- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SHIBO

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

10000 KG

-

Name:

-

Hard rock breaking machine stone crusher plant stone crushing line

-

Model:

-

1-1000TPH

-

Suitable for:

-

All kinds of stone

-

Max feeding size:

-

130-1200mm

-

Final product size:

-

depends on customer needs

-

Voltage and frequency:

-

Customizable

-

Color:

-

Customizable

-

Spare parts supply:

-

Anytime

-

Installation:

-

Under Engineer's Guide

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Application:

-

Stone,Gold Mining Crushing/Breaking

-

Capacity(t/h):

-

1-1000t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHIBO

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

10000 KG

-

Name:

-

Hard rock breaking machine stone crusher plant stone crushing line

-

Model:

-

1-1000TPH

-

Suitable for:

-

All kinds of stone

-

Max feeding size:

-

130-1200mm

-

Final product size:

-

depends on customer needs

-

Voltage and frequency:

-

Customizable

-

Color:

-

Customizable

-

Spare parts supply:

-

Anytime

-

Installation:

-

Under Engineer's Guide

-

After-sales Service Provided:

-

Video technical support

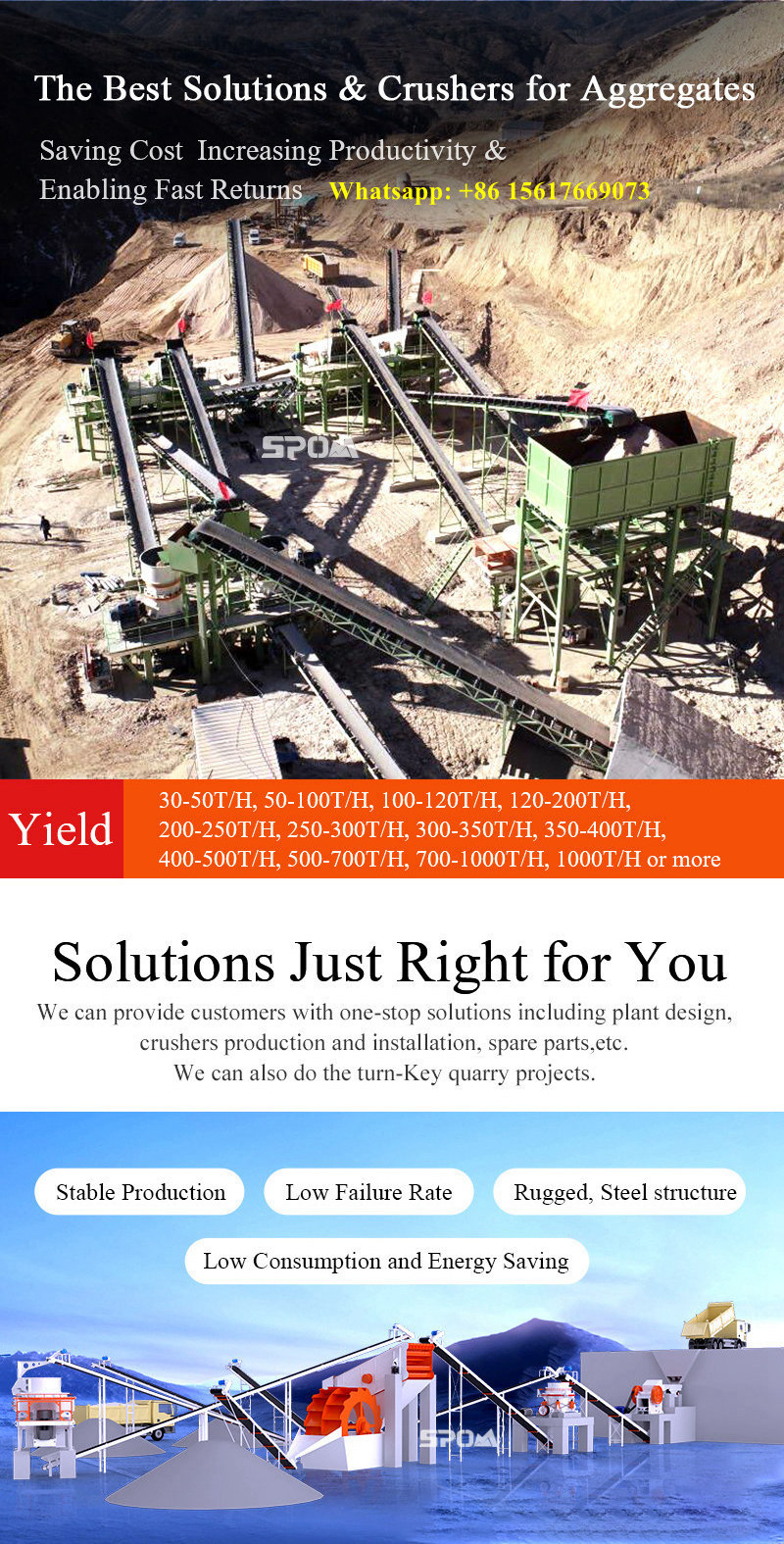

Hard rock breaking machine stone crusher plant stone crushing production line

Product Description

The quarry machine stone crusher crushing plant

line is normally used for:

Quarry

,

Mining

and

Construction waste recycling

. It

can make sand, gravel, and aggregate from many kinds of rocks like pebble, basalt, feldspar, granite, limestone, construction waste, etc. We will help you design complete stone crushing plant to meet the processing requirement of raw materials.

According to production capacity, we can design

30TPH-50TPH-100TPH-200TPH-300TPH-500TPH-800TPH-1000TPH complete stone

crushing plant for you.

According to max feeding size, the crusher can handle 130-1200mm size stone, but the feeding size is related to production capacity & cost, only big crusher have big feeding size which is expensive.

According to final product size, our machine can produce 0-5mm, 5-10mm, 10-15mm,

15-20mm, 20-40mm, 40-80mm, or

3/8, 1/2, 1/4, 3/4,

etc.

depends on your needs.

According to Stone hardness, there have several kinds of design, for example: Jaw crusher + cone crusher, Jaw crusher + impact crusher,

Jaw crusher + sand making machine,

jaw crusher + hammer crusher, hammer crusher + tertiary impact crusher, etc.

Our design team configures various layouts by using our different types and sizes of feeders, crushers, screens, hoppers, washers and conveyors. Our target is always to support our clients to choose the most suitable designs as per their real needs and to help them to avoid mis-investments that will cause waste of finance and/or high operational costs.

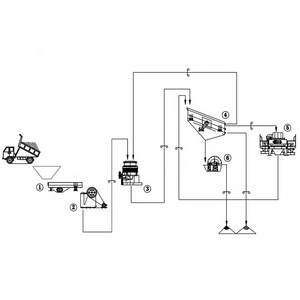

Main Equipment

1.

Vibrating feeder

: to feed the jaw crusher evenly and smoothly.

2. Primary jaw crusher , crush large stones to smaller one.

3. Impact crusher or cone crusher or secondary jaw crusher , to crush stones from primary crusher to smaller gravels or sand.

4. Circular Vibrating screen to classify the gravels to different groups.

5. Belt conveyors , for materials conveying and connect the equipment together.

6. Control panel , to control the equipment motors.

Sand washing machine, sand making machine and other machines can be added to this line to meet the various customers' requirements.

2. Primary jaw crusher , crush large stones to smaller one.

3. Impact crusher or cone crusher or secondary jaw crusher , to crush stones from primary crusher to smaller gravels or sand.

4. Circular Vibrating screen to classify the gravels to different groups.

5. Belt conveyors , for materials conveying and connect the equipment together.

6. Control panel , to control the equipment motors.

Sand washing machine, sand making machine and other machines can be added to this line to meet the various customers' requirements.

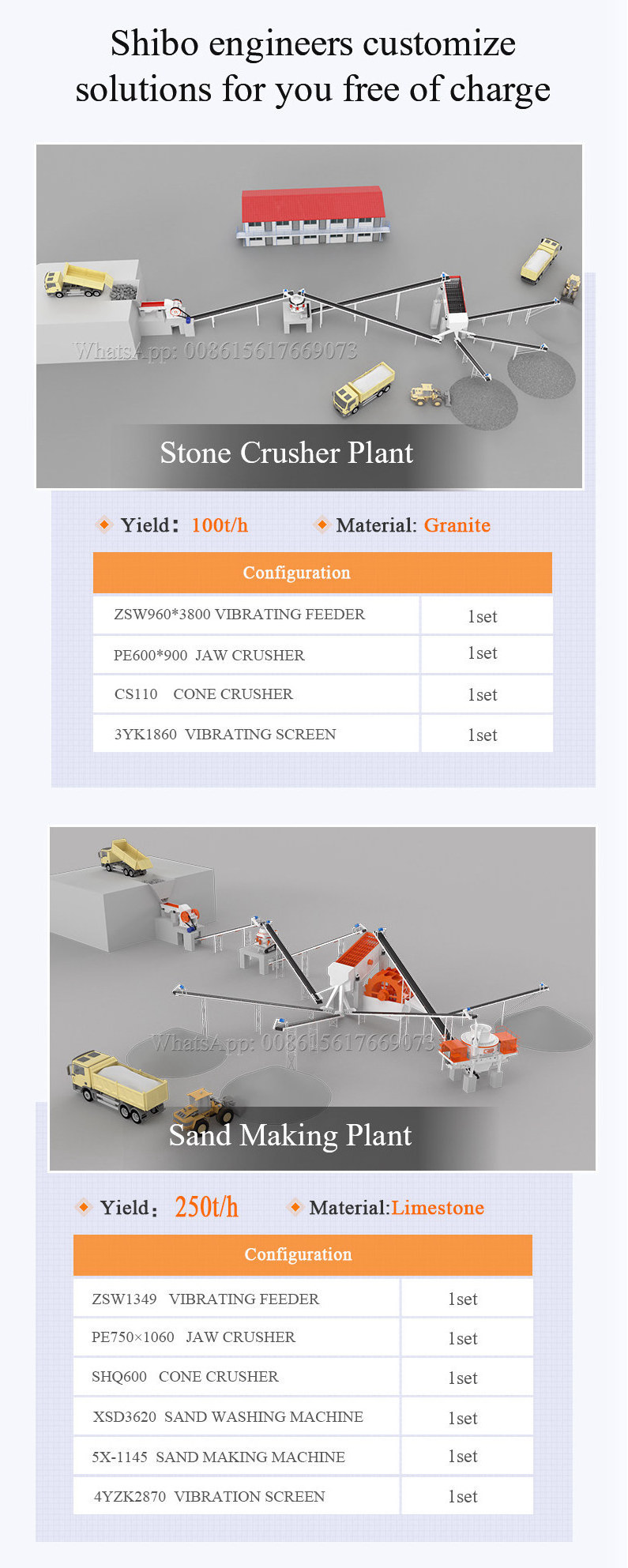

Specification

In order to let you have an idea about the production line configuration and cost, here are some project equipment cost for your reference, this is only the roughly cost of crushing plant.

|

Equipment Configuration

|

|

|

|

|||

|

Model

|

30-50tph

|

60-80tph

|

80-120tph

|

|||

|

Vibrating Feeder

|

ZSW650*2300

|

ZSW850*3000

|

ZSW960*3800

|

|||

|

Jaw Crusher

|

PE400*600

|

PE500*750

|

PE600*900

|

|||

|

Impact Crusher

|

PF1007 / PF1010

|

PF1010

|

PF1214 / PF1315

|

|||

|

or Cone Crusher

|

PYB900

|

CS75

|

CS110

|

|||

|

Vibrating Screen

|

3YK1548

|

3YK1848

|

3YK1860

|

|||

|

Price

|

60,000-80,000 USD

|

85,000-110,000 USD

|

110,000-140,000 USD

|

|||

|

|

|

|

|

|||

|

Model

|

150-200tph

|

180-220tph

|

300tph

|

|||

|

Vibrating Feeder

|

ZSW1100*4200

|

ZSW1100*4200

|

ZSW1300*4900

|

|||

|

Jaw Crusher

|

PE750*1060

|

PE900*1060

|

PE900*1200

|

|||

|

Impact Crusher

|

PF1315

|

PF1320 / PF1210*2

|

PF1315*2

|

|||

|

or Cone Crusher

|

CS220

|

CS160*2

|

CS250+CS110

|

|||

|

Vibrating Screen

|

3YK2160

|

3YK1860*2

|

3YK2460*2

|

|||

|

Price

|

160,000-200,000 USD

|

190,000-365,000 USD

|

______

|

|||

Working Site

Packing & Delivery

Depends on machine size and weight, <6 ton and 6CBM can be packing in wooden box, bigger machine are nude packing, the motor packing in wooden box.

Hot Searches