- Product Details

- {{item.text}}

Quick Details

-

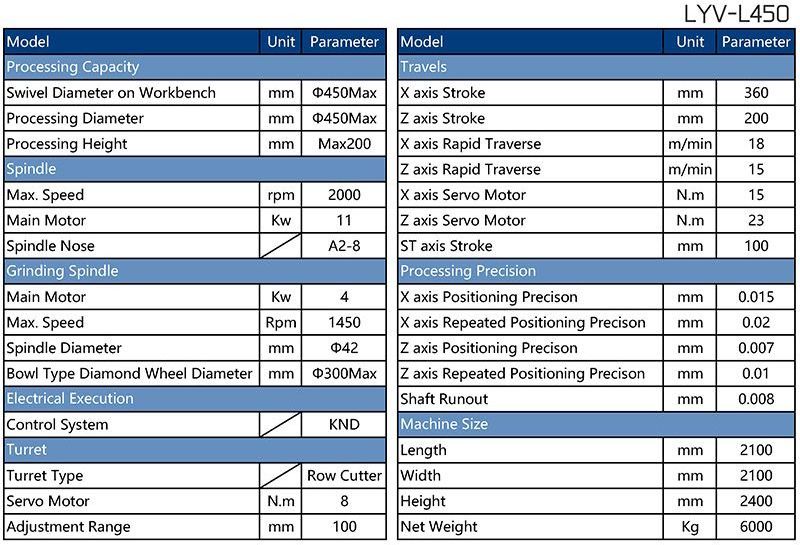

Weight (KG):

-

6000

-

Power (kW):

-

11

-

Core Components:

-

principal axis

-

Product name:

-

CNC vertical turning and grinding machine tool

-

Turret:

-

Row Cutter

-

Processing Diameter:

-

450mm

-

Shaft Runout:

-

0.008mm

-

X axis Positioning Precison:

-

0.015mm

-

X axis Repeated Positioning Precison:

-

0.007mm

-

Max. Speed:

-

2000rpm

-

X axis Stroke:

-

360mm

-

Z axis Stroke:

-

200mm

-

Main Motor:

-

11KW

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hengga

-

Dimension(L*W*H):

-

210*210*240

-

Weight (KG):

-

6000

-

Power (kW):

-

11

-

Core Components:

-

principal axis

-

Product name:

-

CNC vertical turning and grinding machine tool

-

Turret:

-

Row Cutter

-

Processing Diameter:

-

450mm

-

Shaft Runout:

-

0.008mm

-

X axis Positioning Precison:

-

0.015mm

-

X axis Repeated Positioning Precison:

-

0.007mm

-

Max. Speed:

-

2000rpm

-

X axis Stroke:

-

360mm

-

Z axis Stroke:

-

200mm

-

Main Motor:

-

11KW

Products Description

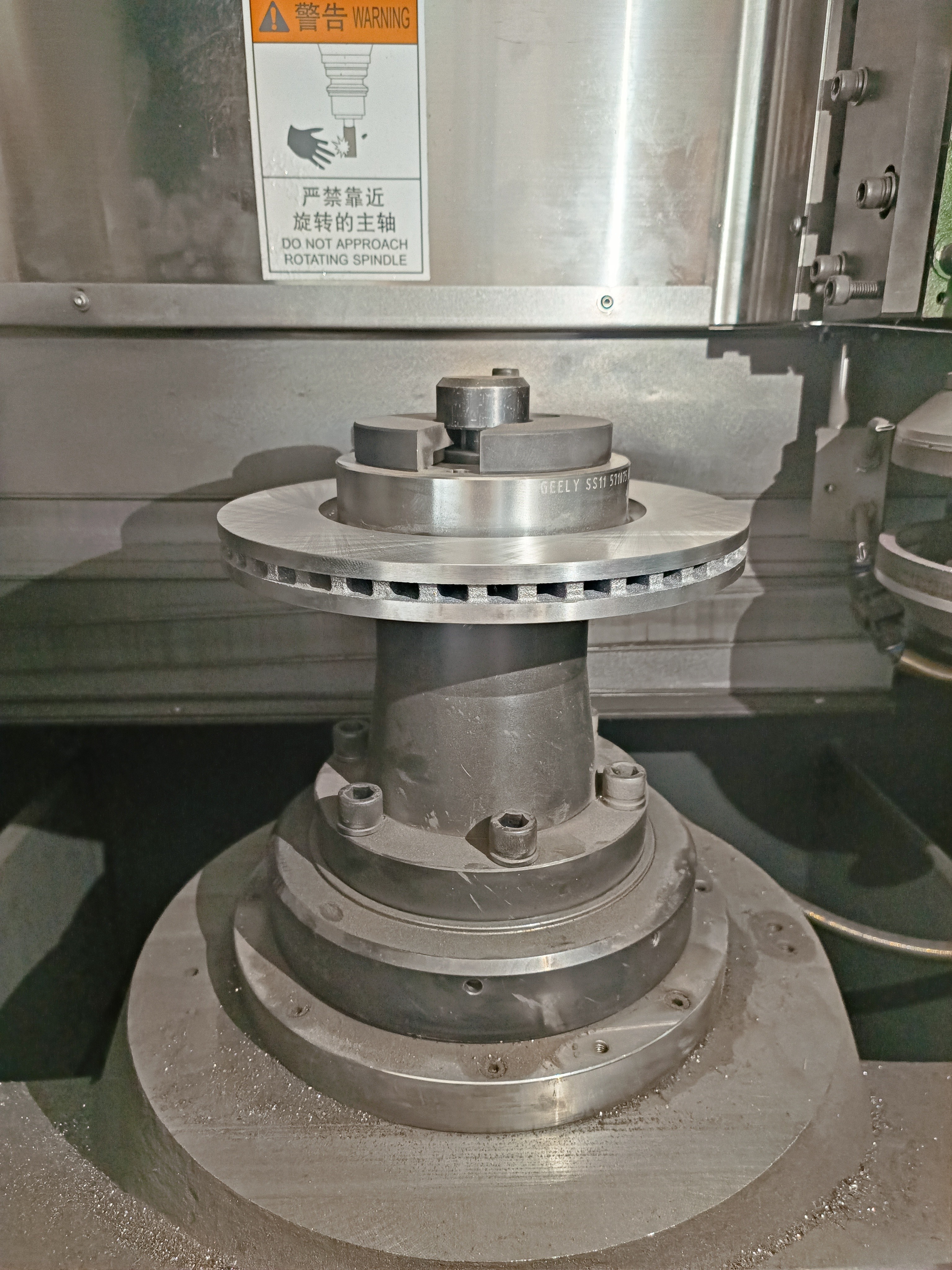

Hengga LYV-L450 P

recision Automated CNC Brake Disc And Drum Grinding Machine Plate Grinding CNC Machine Vertical Surface Grinder

Main Features

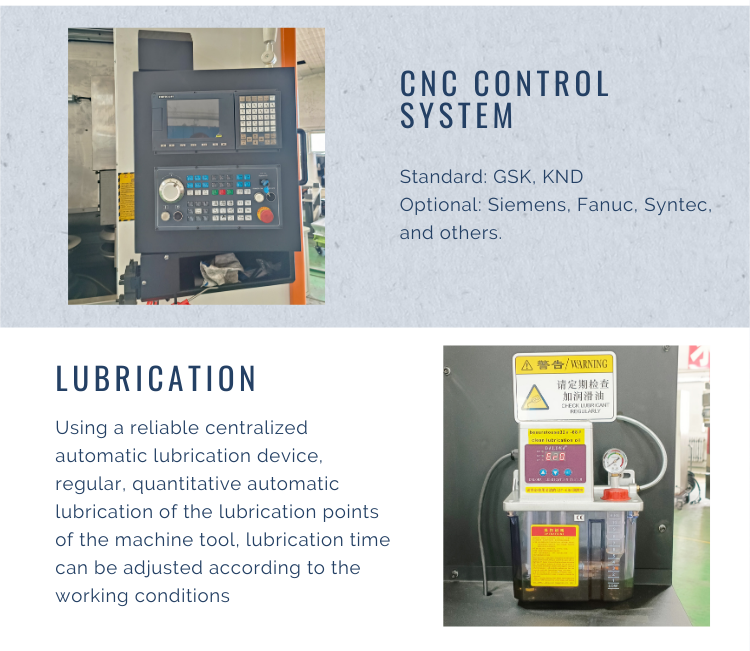

1. The LYV-L450 is a vertical turning and grinding machine, meet the high volume and fast cycle time demands of brake disc production. It's equipped with high speed steel and carbide cutting tools to process internal and external cylinders, end faces, grooving, chamfering and other processes. The CBN grinding wheel can be used for end grinding of disc, ring and complex disc, short shaft metal parts.

2. Heavy duty slide rails, integral base castings and hardened wheel head guides create a solid, rigid machine structure that minimizes vibration, movement and displacement.

3. By combining turning and grinding operations in one machine, fast processing is ensured and the unit cost of brake discs is reduced.

2. Heavy duty slide rails, integral base castings and hardened wheel head guides create a solid, rigid machine structure that minimizes vibration, movement and displacement.

3. By combining turning and grinding operations in one machine, fast processing is ensured and the unit cost of brake discs is reduced.

4. With the LYV-L450 series of grinding compound lathers, Hengga offers production solutions that combine quality, productivity and process reliability.

5. Hengga machines meet the high volume and fast cycle time demands of brake disc production.

6. As a specialist in vertical machining of brake discs, Hengga has worked closely with customers to create a number of customized, turnkey manufacturing solutions. We are committed to providing fully automated manufacturing solutions for the processing of brake discs.

Quick View List

|

Product Model

|

LYV-L450 CNC Vertical Turning And Grinding Lathe

|

|

Application Area

|

Flange

Brake Disc & Drums

Automobile Wheel Hubs

Flywheels

Clutch Plate and Housings

|

|

Processing Procedure

|

Finish Turning

Grinding Double Surface Of Workpiece

|

|

MOQ

|

1 Unit

|

|

Payment Terms

|

T/T, L/C, Paypal, Westunion, Alibaba.com Pay

30% in advance, 70% before shipping

|

|

Packaging Method

|

Wooden case(LCL) / Steel Pallet(FCL)

|

|

Leading Time

|

1 unit--45 days

2-5 units--60 days

>5 units--To be negotiated

|

Product Paramenters

Details Images

Recommend Products

Hot Searches