- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8.5*1.65*1.5m

-

Weight:

-

2500 kg

-

Marketing Type:

-

New Product

-

Product name:

-

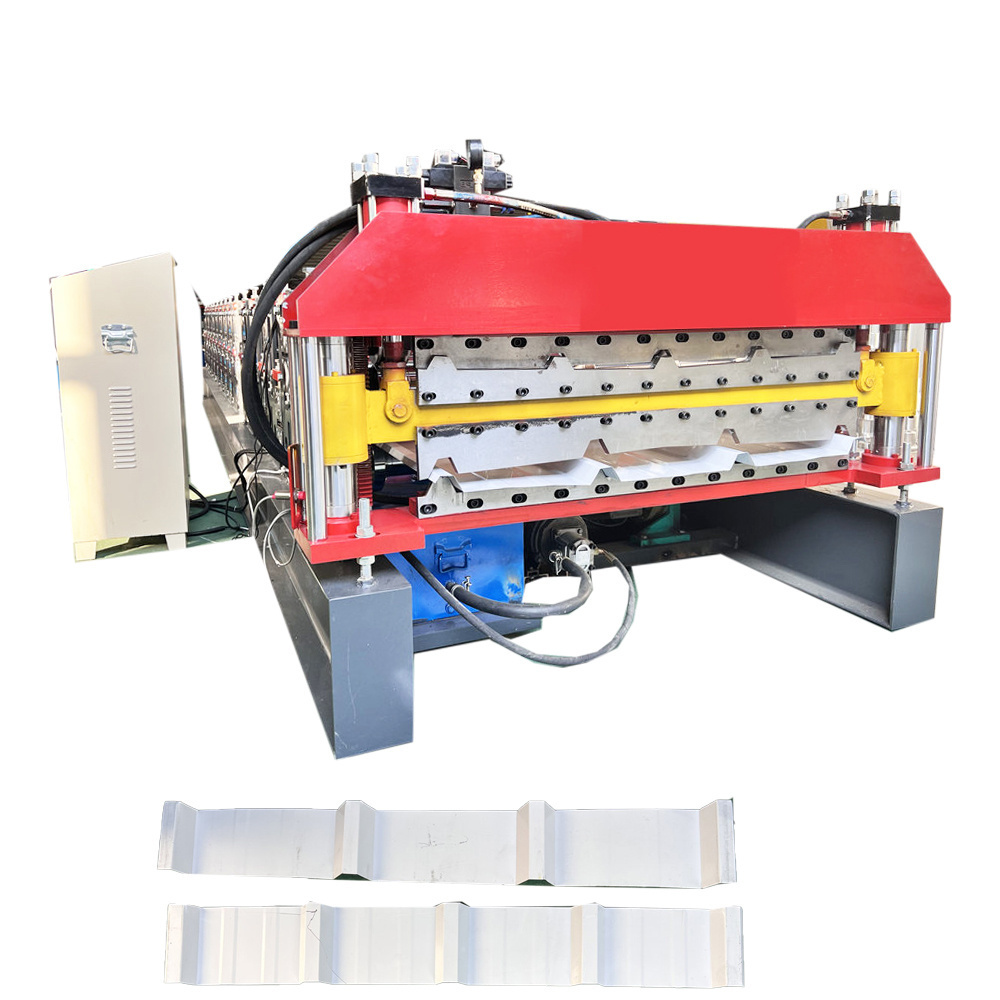

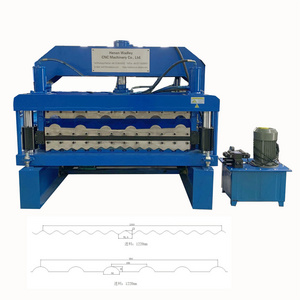

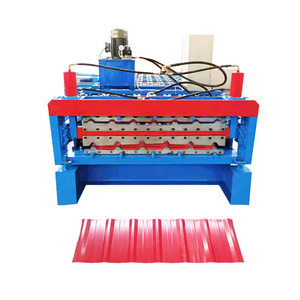

Roll Forming Machine

-

Machine type:

-

Automatic

-

Usage:

-

Steel Construction

-

Shaft material:

-

High Grade No.45 Forged

-

Raw material:

-

Color steel sheet or galvanized steel sheet

-

Material thickness:

-

0.3-0.8 mm or customized

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

Main frame:

-

350H Steel

-

Keywords:

-

Full Automatic Roofing Sheet Roll Forming Machine

Quick Details

-

Type:

-

Roll Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

12m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8.5*1.65*1.5m

-

Weight:

-

2500 kg

-

Marketing Type:

-

New Product

-

Product name:

-

Roll Forming Machine

-

Machine type:

-

Automatic

-

Usage:

-

Steel Construction

-

Shaft material:

-

High Grade No.45 Forged

-

Raw material:

-

Color steel sheet or galvanized steel sheet

-

Material thickness:

-

0.3-0.8 mm or customized

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

Main frame:

-

350H Steel

-

Keywords:

-

Full Automatic Roofing Sheet Roll Forming Machine

Products Overview

- Instruction for roof sheet making roll forming machine

The machine is composed of the Frame, PLC control system, hydraulic station, and automatic shearing system.

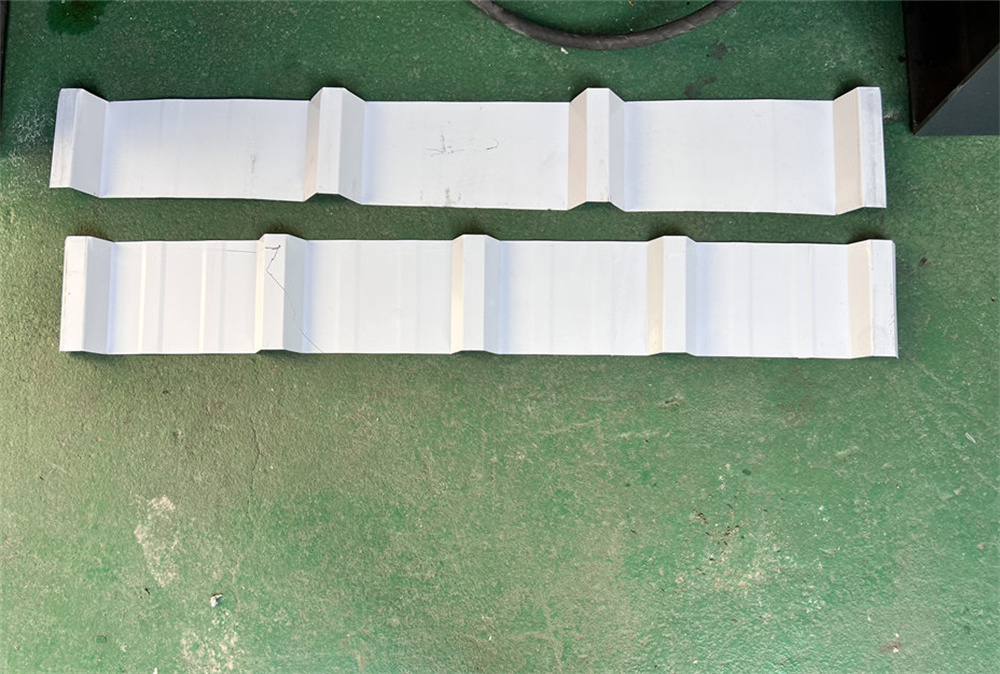

The tile/roof produced are flat and beautiful in appearance, uniform in paint pattern, and are widely used in industrial and civil buildings, such as houses, warehouses, garages, hangars, gymnasiums, exhibition halls, theaters and other room surfaces and walls.

- Features for

roof sheet making roll forming machine

The machine adopts high-level automatic control software to realize production information management. The whole unit automation control system adopts a highly integrated network, which makes the automation system have superior performance.

It also has the advantages of easy operation, easy maintenance and debugging, and easy mold replacement.

- Working flow of roof sheet making roll forming machine

Decoiler-roll forming machine-PLC control box-hydraulic cutter-Run out table

Specification

|

Part details

|

Item Name

|

Specification

|

|

Material

|

Raw material

|

Galvanized steel or PPGI

|

|

|

Thickness

|

0.3-0.8 mm

|

|

Machine

|

Roller station

|

11

|

|

|

Shaft diameter

|

70 mm

|

|

|

Shaft material

|

45# steel with 0.05mm chrome

|

|

|

Roller material hardness 30-40 HRC

|

45# steel with 0.05mm chrome

|

|

|

Machine size

|

About 6.2×1.5×1.3 m

|

|

|

Machine weight

|

About 4.5 ton

|

|

|

Machine color

|

As customer' request

|

|

|

Working speed

|

8-20 m/min

|

|

Cutter

|

Hardness

|

50-65 HRC

|

|

|

Cutting tolerance

|

± 1 mm

|

|

|

Material

|

Cr 12

|

|

|

Operate

|

Hydraulic cutting

|

|

Power

|

Driving way

|

Chain 1 inch

|

|

|

Main power

|

4 kw

|

|

|

Pump power

|

3 kw

|

|

|

Voltage

|

380v/50HZ,3P or customize

as customer' request |

|

Control system

|

PLC brand

|

Delta made in Twaiwan

|

|

|

Screen

|

Touchable screen

|

|

|

Language

|

Chinese and English or add language as customer need

|

|

Decoiler

|

Operation

|

Manual

|

|

|

Weight capicatity

|

5 ton

|

|

|

Price

|

Free as gift

|

|

Receiving table

|

Operation

|

Manual

|

|

|

Length

|

3 m

|

|

|

Price

|

Free as gift

|

5T MANUALDECOILER

FEEDING PLATFORM

HYDRAULIC CUTTING DEVICE

PLC CONTROL SYSTEM

HYDRAULIC PUMP STATION

3M MANUAL RECEIVING TABLE

Recommend Products

840 roofing sheet roll forming machine | metal roof roll forming machine | metal roof machine | trapezoidal sheet roll forming machine | roofing sheet making machine | wall sheet roll forming machine

840 trapezoidal sheet roll forming machine popular sell in many countries, Coil width before rolling is 1000mm /1200mm / 1250mm. After rolling product width is 840mm, Material common is PPGI material, material thickness common between 0.3-0.8 mm. Machine details is like up type:

1000 roofing sheet roll forming machine | metal roof roll forming machine | metal roof machine | trapezoidal sheet roll forming machine | roofing sheet making machine | wall sheet roll forming machine

1000 trapezoidal sheet roll forming machine popular sell in many countries, Coil width before rolling is 1200mm /1220mm / 1250mm. After rolling product width is 1000mm, Material common is PPGI material, material thickness common between 0.3-0.8 mm. Machine details is like up type:

1000 trapezoidal sheet roll forming machine popular sell in many countries, Coil width before rolling is 1200mm /1220mm / 1250mm. After rolling product width is 1000mm, Material common is PPGI material, material thickness common between 0.3-0.8 mm. Machine details is like up type:

1064 Corrugated roll forming machine | corrugated roofing sheet machine | corrugated machine | 850 corrugated roofing sheet machine

Corrugated roofing sheet roll forming machine popular sell in many countries, Coil width before rolling is 1000mm / 1200mm /1220mm / 1250mm. Material common is PPGI material, material thickness common between 0.3-0.8 mm. Machine details is like up type:

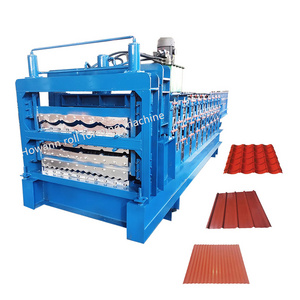

Glazed tile machine | step tile machine | C tile machine | tile make machine | roof tile roll forming machine

Glazed tile roll forming machine popular sell in many countries, Coil width before rolling is 1000mm / 1200mm /1220mm / 1250mm. Material common is PPGI material, material thickness common between 0.3-0.8 mm. Machine details is like up type:

Glazed tile roll forming machine popular sell in many countries, Coil width before rolling is 1000mm / 1200mm /1220mm / 1250mm. Material common is PPGI material, material thickness common between 0.3-0.8 mm. Machine details is like up type:

Why Choose Us

♥ Over 20 years of experience.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

Our Technical Personnel Provide On-Site Services Overseas:

Our technical personnel arrive at the customer's site in Malaysia for technical guidance and training,If a customer encounters technical problems that are difficult to solve during use, we usually send professional and technical personnel to foreign customer sites for guidance and training. Therefore, if you want to do business in cold bending forming equipment, please feel free to contact our customer service personnel at any time.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

Our Technical Personnel Provide On-Site Services Overseas:

Our technical personnel arrive at the customer's site in Malaysia for technical guidance and training,If a customer encounters technical problems that are difficult to solve during use, we usually send professional and technical personnel to foreign customer sites for guidance and training. Therefore, if you want to do business in cold bending forming equipment, please feel free to contact our customer service personnel at any time.

Hot Searches