- Product Details

- {{item.text}}

Quick Details

-

Capacity:

-

10 turn-key solutions per month

-

PLC:

-

Siemens

-

Function:

-

Sand casting

-

Easy operation:

-

Automatic Control

-

Feature:

-

Easy Operate

-

Advantage:

-

High Output

-

Key words:

-

Resin sand casting

-

Raw material:

-

Steel Iron

-

Machine color:

-

Custromized

-

Weight:

-

Customized

-

Certification:

-

ISO9001:2008

Quick Details

-

Place of Origin:

-

China

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Application:

-

Large complex thin wall castings

-

Capacity:

-

10 turn-key solutions per month

-

PLC:

-

Siemens

-

Function:

-

Sand casting

-

Easy operation:

-

Automatic Control

-

Feature:

-

Easy Operate

-

Advantage:

-

High Output

-

Key words:

-

Resin sand casting

-

Raw material:

-

Steel Iron

-

Machine color:

-

Custromized

-

Weight:

-

Customized

-

Certification:

-

ISO9001:2008

How to stop wasting your money on casting right now and never waste it again? Read this!

You can get turn-key solutions from us with #V-process casting machine #Lost foam casting machine #Resin sand casting machine and so on.

We have rich experience in handling orders for heavy buyers with the professional process.

- Stable raw material purchasing

- Favorable orders follow-up management

- Laudable lead-time & shipment control

- Traceable quality evaluation

- Flexible payment terms

- Remarkable after-sale service

Resin sand casting plays a role of barrier and isolation between the casting and the mold to achieve the purpose of anti-sticking sand, effectively prevent the oxidation of high-temperature liquid metal, so that there is no chemical reaction in the contact process between the mold and high-temperature liquid metal, and can absorb and digest nitrogen, sulfur, carbon and other gases.

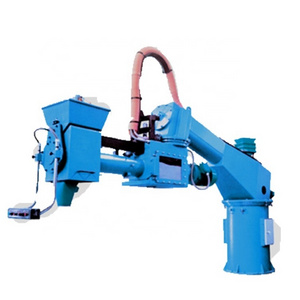

Equipment

Magnetic separation belt conveyor, vibration crusher regenerator, centrifugal rotor secondary regenerator, sand silo, bucket elevator (3 sets), mobile double arm continuous resin sand mixer, pulse back blowing dust remover, etc.

Technical advantages

| 1 | The resin sand equipment is highly automated, easy to operate, and reduces labor costs. |

| 2 | The resin sand equipment is arranged in compact order, saving a lot of land. |

| 3 | The resin sand equipment adopts rubber spring with low noise. |

| 4 | Each equipment dust point of resin sand equipment is equipped with air vent, connected with a dust remover, and the working environment is clean. |

| 5 | The molding sand processed by resin sand equipment is of high purity, which greatly saves the consumption of resin and curing agent (resin consumption is 1% - 1.2 of molding sand). |

| 6 | After the resin sand equipment is unpacked, the surface of the casting is smooth and the accuracy of the external dimension of the casting is high. |

| 7 | Resin sand equipment shall ensure that castings are dense and free of air holes. |

| 8 | The stirrer blade of resin sand mixer of resin sand equipment is made of tungsten steel alloy, which is hard and durable. |

| 9 | The crushing basket of resin sand equipment vibration crusher is made of 16Mn low alloy steel with long service life. |

| 10 | Resin sand equipment the resin sand mixer adopts PLC automatic program control, with less head and tail sand. |

Process flow of resin sand production line:

1. The used sand is naturally cooled and then enters the conveyor and magnetic separator, and then enters the crusher after magnetic separation.

2. The crushed sand is lifted from 1# elevator to the secondary regeneration machine and then is lifted from 2# elevator to the sand depot after magnetic separation.

3. It is then modeled by a double arm continuous sand mixer with a mobile trolley.