- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

25

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.3 - 1.8 mm

-

Heating Power (kW):

-

69 kW

-

Air Comsumption(L/min):

-

2000 L/min

-

Water Comsumption(L/min):

-

8.4 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LITAI MACHINERY

-

Voltage:

-

custom

-

Dimension(L*W*H):

-

L6000*W2200*H2700mm

-

Weight (T):

-

5 T

-

Power(KW):

-

98

-

Machine Name:

-

Fully automatic plastic thermoforming machine

-

Application:

-

Making plastic disposable cups/plates/bowls/containers/lids etc.

-

keyword:

-

disposable plastic glass cup making machine

-

Finished Products:

-

Plastic products

-

Suitable Sheet:

-

PP/PS/HIPS/PET/PVC etc.

-

Forming Principle:

-

Positive pressure forming

-

Controlled:

-

PLC & Touch Screen

-

Hydraulic System:

-

Positive and negative pressure

-

Model:

-

4 Pillar

Quick Details

-

Max.Forming Height(mm):

-

180 mm

-

Forming Width (mm):

-

650 mm

-

Forming Length (mm):

-

320 mm

-

Production Speed(Cycles/min):

-

25

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.3 - 1.8 mm

-

Heating Power (kW):

-

69 kW

-

Air Comsumption(L/min):

-

2000 L/min

-

Water Comsumption(L/min):

-

8.4 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LITAI MACHINERY

-

Voltage:

-

custom

-

Dimension(L*W*H):

-

L6000*W2200*H2700mm

-

Weight (T):

-

5 T

-

Power(KW):

-

98

-

Machine Name:

-

Fully automatic plastic thermoforming machine

-

Application:

-

Making plastic disposable cups/plates/bowls/containers/lids etc.

-

keyword:

-

disposable plastic glass cup making machine

-

Finished Products:

-

Plastic products

-

Suitable Sheet:

-

PP/PS/HIPS/PET/PVC etc.

-

Forming Principle:

-

Positive pressure forming

-

Controlled:

-

PLC & Touch Screen

-

Hydraulic System:

-

Positive and negative pressure

-

Model:

-

4 Pillar

*

Pictures and related technical parameters of products will be updated continuously without prior notice.The right of final interpretation of this information belongs to our company.

Product Paramenters

|

Technical Parameters

|

|

|

||

|

Model

|

TQC-750

|

TQC-650B

|

||

|

Max. Forming Area

|

750*480mm

|

650*320mm

|

||

|

Max. Forming Depth

|

125-180mm(custom height)

|

|

||

|

Sheet Thickness

|

0.3-1.8mm

|

|

||

|

Sheet Width

|

760mm

|

650mm

|

||

|

Max. Forming Speed

|

30 times/min

|

|

||

|

Air Pressure

|

0.6-0.8mpa

|

|

||

|

Air Consumption

|

3.0m³/min

|

2.0m³/min

|

||

|

Water Consumption

|

0.7m³/h

|

0.5m³/h

|

||

|

Rated Power

|

140Kw

|

98Kw

|

||

|

Used Power

|

98Kw

|

72Kw

|

||

|

Power Supply

|

AC 380V,50Hz, Three-phase, Four-wire

|

|

||

|

Dimension

|

L8500*W2200*H3200mm

|

L7000*W2000*H3100mm

|

||

|

Weight

|

About 6.5T

|

About 5T

|

||

|

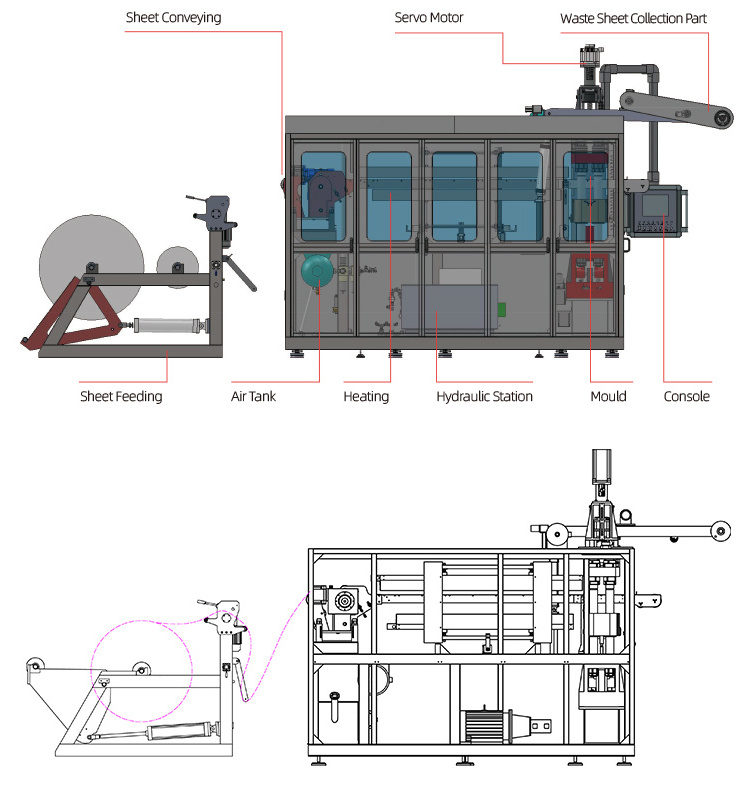

MACHINE MAIN PARTS

|

|

|

|

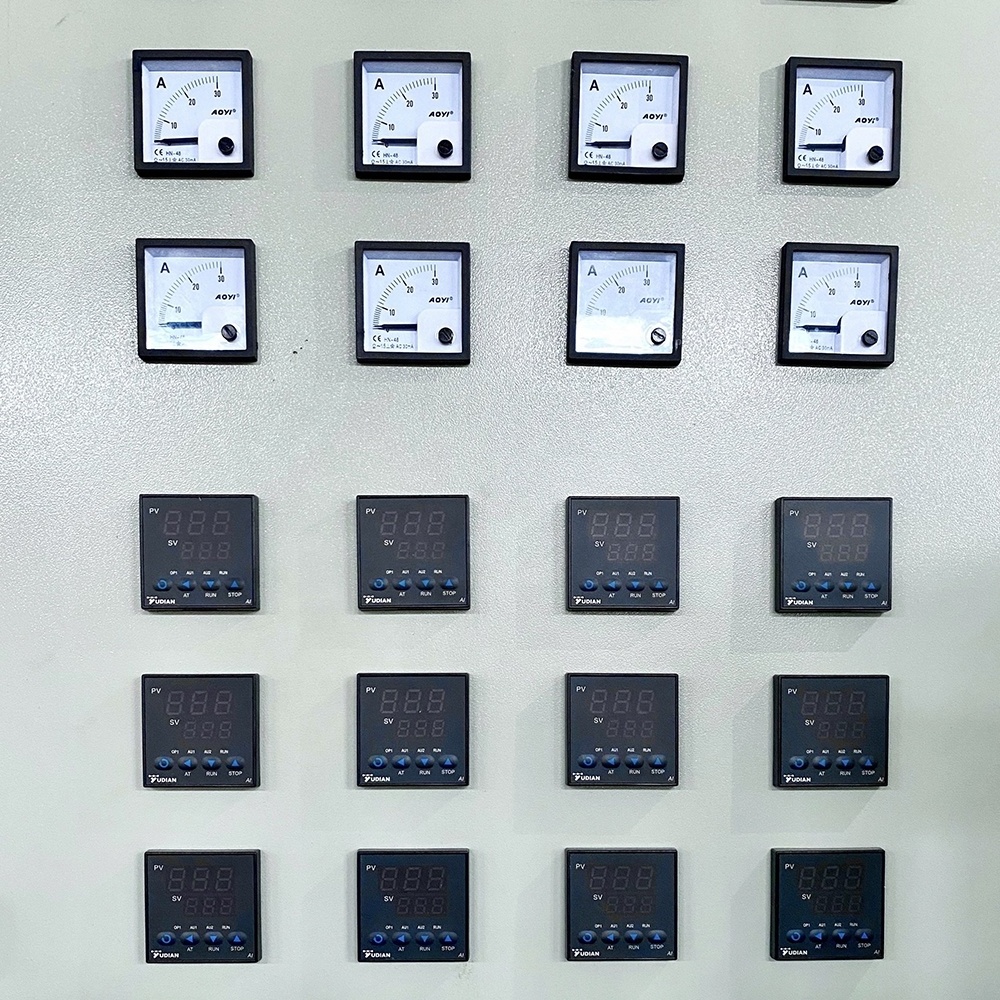

Touch Screen/PLC

|

SIEMENS (Germany)

|

|

|

Servo Motor

|

YASKAWA (Japan)

|

|

|

AC Contactor/Circuit Breaker

|

SCHNEIDER (France)

|

|

|

Proximity Switch

|

ROCKWELL (USA)

|

|

|

Solenoid Directional Valve/solenoid overflowing valve/counterbalance valve

|

YUKEN (Taiwan)

|

|

|

Intermediate relay

|

IDEC (Japan)

|

|

|

Intermediate relay base

|

OMRON (Japan)

|

|

|

Forming Valve

|

CKD (Japan)

|

|

|

Solenoid Valve

|

SMC (Japan) / Mindman (Taiwan)

|

|

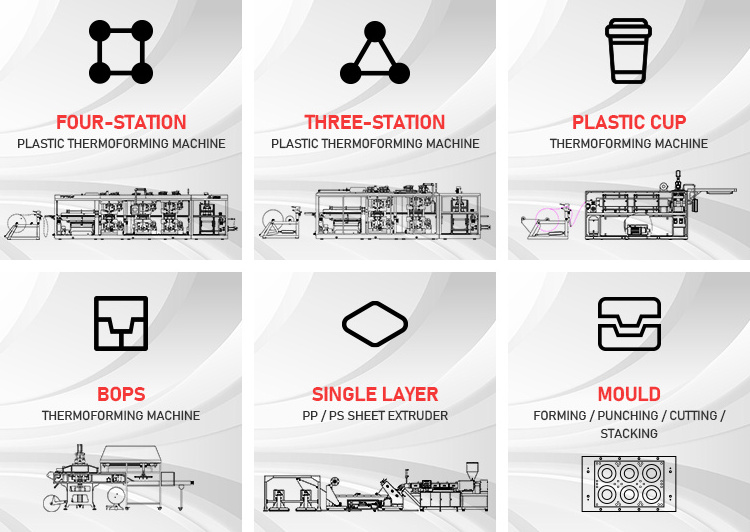

Products Description

APPLICATION

Plastic cup thermoforming machine is our lasted developed product, Sheet feeding and stretching part are driven by servo

motor.Machine produces disposable products, such as plastic cup, bowl, lid, and box through the workflow of sheet feeding, sheet heating, forming, cutting and blowing, widely used and suitable for most of the customer requested. PLC for program, manual interface for operation, stable, low noise, and high efficiency.

motor.Machine produces disposable products, such as plastic cup, bowl, lid, and box through the workflow of sheet feeding, sheet heating, forming, cutting and blowing, widely used and suitable for most of the customer requested. PLC for program, manual interface for operation, stable, low noise, and high efficiency.

Main Function

1.positive and negative pressure forming device.

2.vacuum forming device.

3.touch screen computer temperature module point to point control function.

4.air control device.

5.cooling device.

6.die, mold temperature control function.

7.automatic punching and cutting function.

8.automatic stack counting function.

9.edge automatic rewinding function.

10.safety protection device.

3.touch screen computer temperature module point to point control function.

4.air control device.

5.cooling device.

6.die, mold temperature control function.

7.automatic punching and cutting function.

8.automatic stack counting function.

9.edge automatic rewinding function.

10.safety protection device.

SUMMARY OF MACHINE

1.Industrial manual interface and PLC of SIEMENS (Germany) make the high degree automation, accurate control and convenient operation. The document storage function simplifies the operational processes.

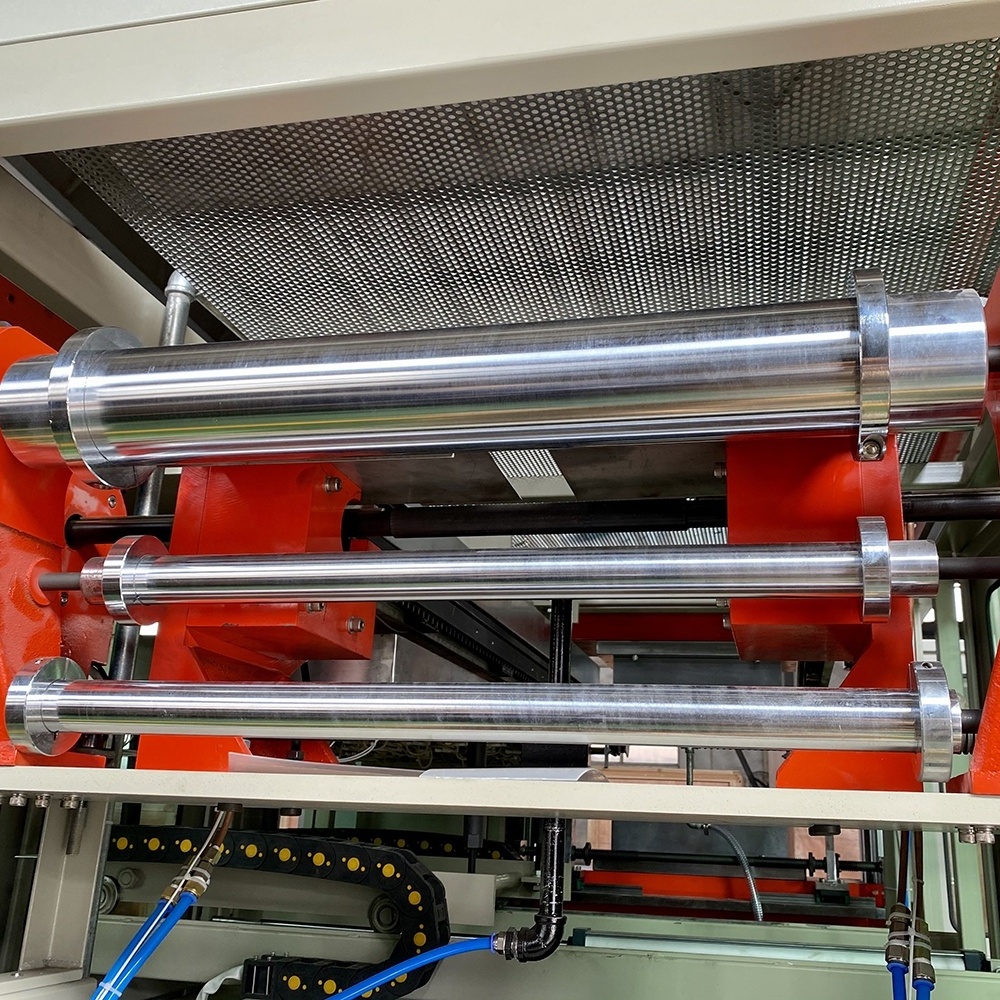

2.Working stations is driven by stable four guiding-pillars (GCr15 steel, outside is hard chrome plated) structure. Wear

resistant, and extend equipment life.

resistant, and extend equipment life.

3.Stretching servomotor of YASKAWA (Japan) controls the speed of the upper and lower die, this can maintain the uniform strength to ensure that the bottom thickness of each cup is uniformly. And the servo motor also controls precisely sheet feeding to avoid wasting.

4.Hydraulic driven system can provide adequately movement speed and strongly punching power.

5.The whole part is driven by hydraulic system, which is reliable and steady. Using proximity switch of ROCKWELL (USA) leads to excellent mould positioning precision.

6.The heater added vacuum insulation cotton, which shows quick response rate, short processing time, and save energy.

7.Sharp chain uses 65#Mn, which has higher strength, better heat resistance and elasticity than 45# steel.

8.The electric lubricating oil pump can automatically inject lubricating oil regularly and quantitatively through the control of computer under the condition of unmanned control, which can make the rotating part of the machine get proper and reasonable lubrication.

9.Sheet feeding servo motor adopt YASKAWA brand, made in Japan, the rated power is 3Kw, ensure stable operation in the process of feeding.

What is features and advantages of our plastic thermoforming machine?

1. Fully servo driven machine.no noise.no vibration,thermoforming good and fast.

2. Fully machine in compact structure,taking small floor space.

3. Can be adapted to a variety of materials,and the products thicker 8% than the average machine products.

4. Furnaces automatic removal device, can be turned down at any time during production without breaking the sheet reaching without wasting materials.

5. Electric furnace temperature control system uses intelligent automatic compensation control,a control,a control of a

regulator,easy to adjust the temperature uniformity,easy to use,simple,fast heating,low temperature three times up and down the oven roast slices.

6. Forming,cutting die servo-driven,two-way adjustable for upper and lower mold stroke,in which the upper mold electric adjustable in clamping direction. The upper and bwer molds height position can be adjusted conveniently and fast under the clamping state;lower mold in clamping direction readily accessible buffer,increasing the clamping speed,avoiding shock.

7. Auto cutting, auto counting,auto transmission by PLC.

8. Labor saving, only 1-2 workers packing.

3. Can be adapted to a variety of materials,and the products thicker 8% than the average machine products.

4. Furnaces automatic removal device, can be turned down at any time during production without breaking the sheet reaching without wasting materials.

5. Electric furnace temperature control system uses intelligent automatic compensation control,a control,a control of a

regulator,easy to adjust the temperature uniformity,easy to use,simple,fast heating,low temperature three times up and down the oven roast slices.

6. Forming,cutting die servo-driven,two-way adjustable for upper and lower mold stroke,in which the upper mold electric adjustable in clamping direction. The upper and bwer molds height position can be adjusted conveniently and fast under the clamping state;lower mold in clamping direction readily accessible buffer,increasing the clamping speed,avoiding shock.

7. Auto cutting, auto counting,auto transmission by PLC.

8. Labor saving, only 1-2 workers packing.

Contact Us

Facebook

https://pse.is/3urql5

LinkedIn

https://pse.is/3ythvl

YouTube

https://pse.is/3zkhvj

Instagram

https://pse.is/3yhe6m

Pinterest

https://pse.is/3vd57m

Tiwtter

https://pse.is/3z675l

Official website

http://www.litai.cc/

Tik Tok

http://pesc.pw/478rpe

Made in China

https://pse.is/3rh2nv

Hot Searches