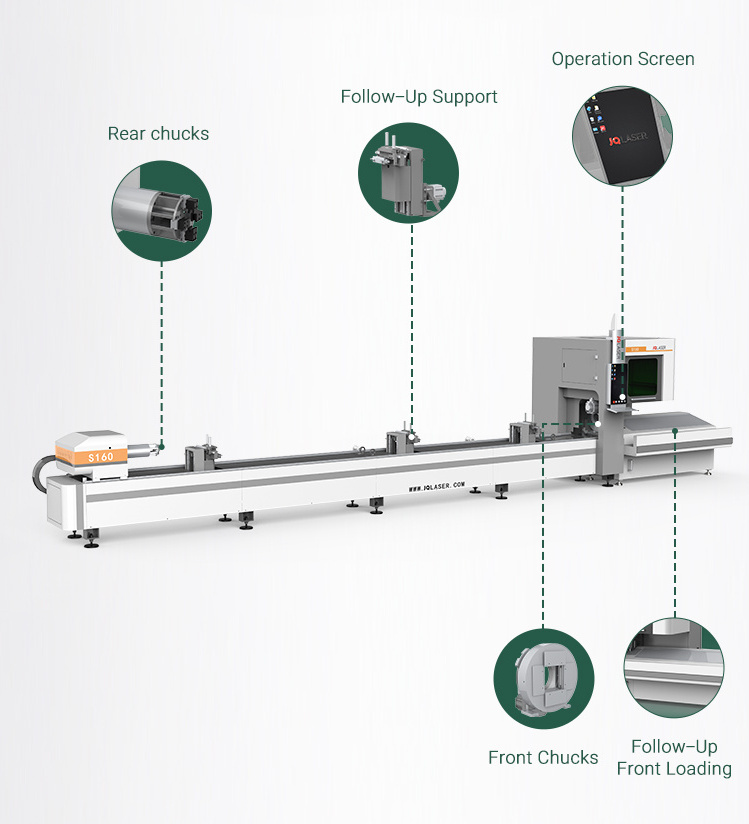

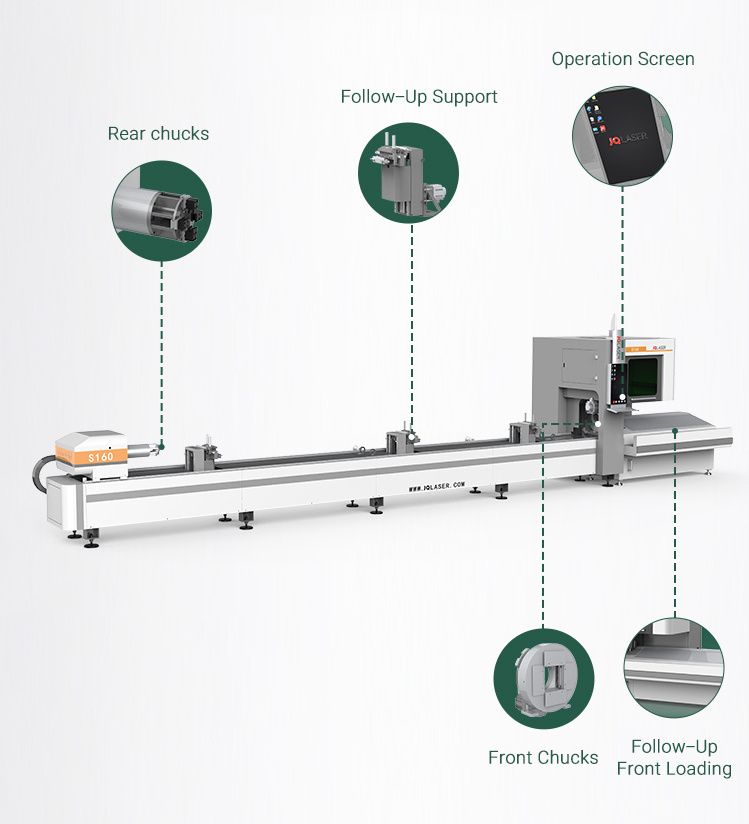

The full-stroke pneumatic (double) chuck design doubles the efficiency; various specifications, support optional matching.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

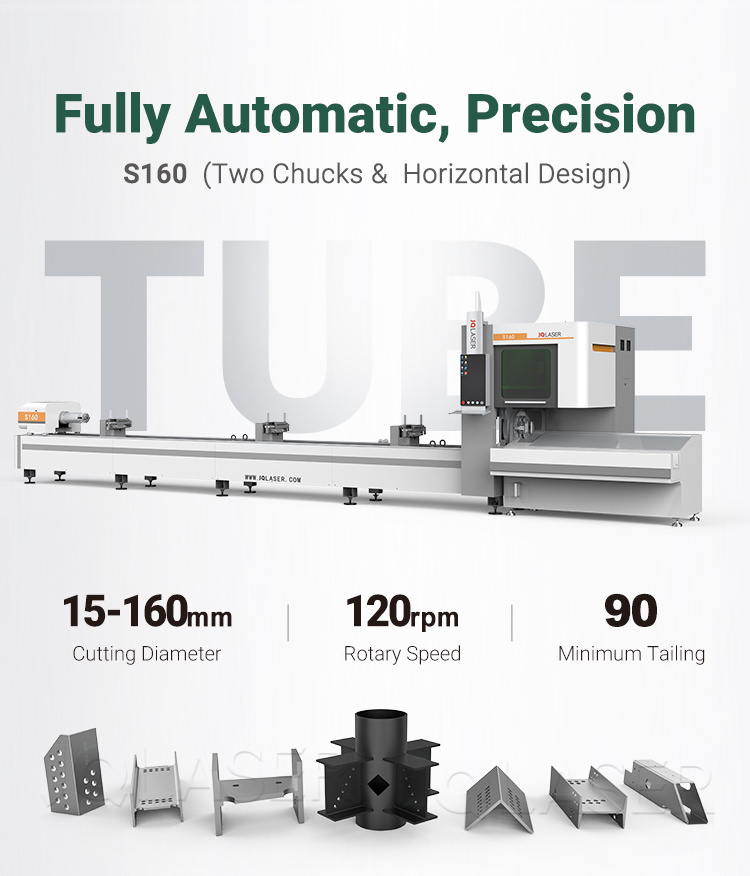

tube diameter:15mm-120mm

-

Cutting Thickness:

-

1-10mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JQ LASER

-

Weight (KG):

-

3500 KG

-

Product name:

-

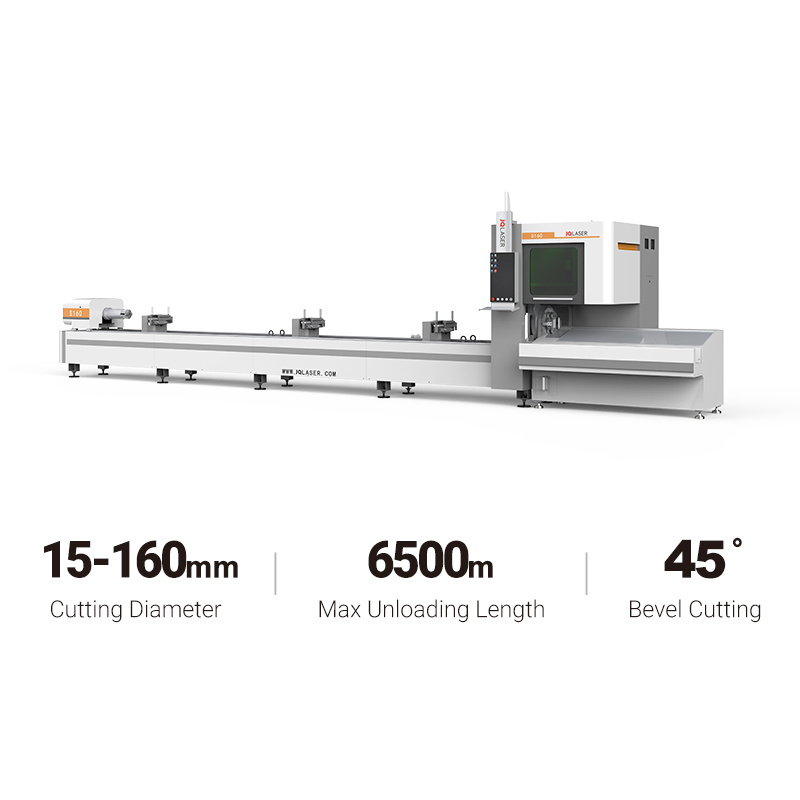

JQ S160 15-160mm Diameter Full Auto Laser Pipe Cut Machine

-

Keyword:

-

15-160mm Diameter Metal Tube Fiber Laser Cut Machine

-

Function:

-

Cutting Tube Metal Materials

-

Laser power:

-

1000W /1500W/ 2000W / 3000W

-

Laser source:

-

Raycus IPG

-

Laser Cutting Head:

-

Raytools Fiber Laser Cutting Head

-

After-sales Service Provided:

-

Online Support

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

90m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

tube diameter:15mm-120mm

-

Cutting Thickness:

-

1-10mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JQ LASER

-

Weight (KG):

-

3500 KG

-

Product name:

-

JQ S160 15-160mm Diameter Full Auto Laser Pipe Cut Machine

-

Keyword:

-

15-160mm Diameter Metal Tube Fiber Laser Cut Machine

-

Function:

-

Cutting Tube Metal Materials

-

Laser power:

-

1000W /1500W/ 2000W / 3000W

-

Laser source:

-

Raycus IPG

-

Laser Cutting Head:

-

Raytools Fiber Laser Cutting Head

-

After-sales Service Provided:

-

Online Support

Product Description

Advantage

:

1.The stability of the cutting:The movement of NC chuck helps to process long workpiece ensuring no vibration with accuracy. 2.Small size and small occupied area, improving the utilization of workshop 3.Optional Automatic Loading and Unloading Device

1.The stability of the cutting:The movement of NC chuck helps to process long workpiece ensuring no vibration with accuracy. 2.Small size and small occupied area, improving the utilization of workshop 3.Optional Automatic Loading and Unloading Device

4.

suitable for the processing of a variety of metal pipes, waist round pipes, round pipes, giant pipes, square pipes, I-beams,channel steels, D-shaped pipes, special-shaped pipes, etc.

Product Paramenters

|

NO.

|

Item

|

Parameter

|

Unit

|

|

1

|

Cut pipe diameter

|

15~160(external circle of workpiece)

|

mm

|

|

2

|

X, Y, Z axis positioning accuracy

|

±0.05/1000mm

|

mm

|

|

3

|

X, Y, Z axis repeat positioning accuracy

|

±0.03/1000mm

|

mm

|

|

4

|

Acceleration speed

|

1g

|

m/s²

|

|

5

|

Max. running speed

|

90

|

m/min

|

|

6

|

Maximum weight of a single pipe

|

120

|

kg

|

|

7

|

Max. speed of chuck

|

120

|

rpm

|

|

8

|

Main machine shape (length, width and height)

|

Approx. 9300×1600×2300

|

mm

|

|

9

|

Laser power

|

1500w/2000w/3000w Optional

|

w

|

|

10

|

Power supply requirements

|

380v/50Hz±10%

|

|

Product Show

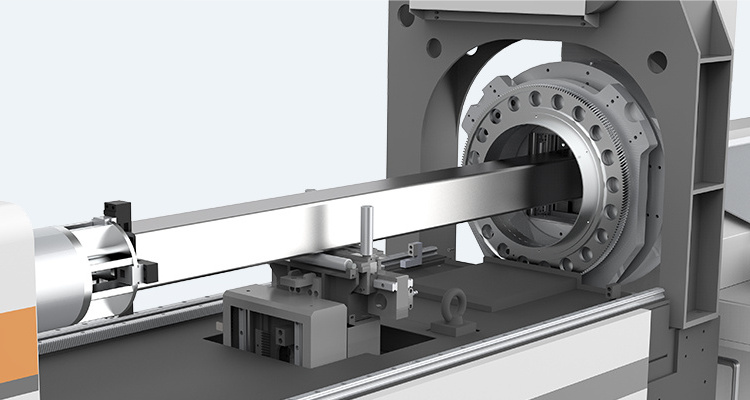

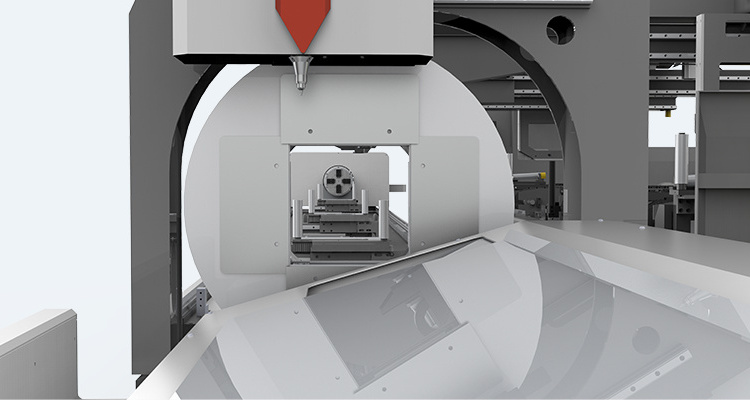

The Chuck Is Clamped For Precise Cutting

Follow-Up Front Splice

Slope type front material receiving,

Front receiving device can complete the continuous cutting of the pipe and improve the processing efficiency.

Follow-on support device

3 sets of follow-up support mechanisms,I

t can reduce processing errors, ensure uniform force on the entire metal pipe, and improve cutting accuracy. Real-time feeding to prevent the reduction of cutting accuracy due to pipe distortion.

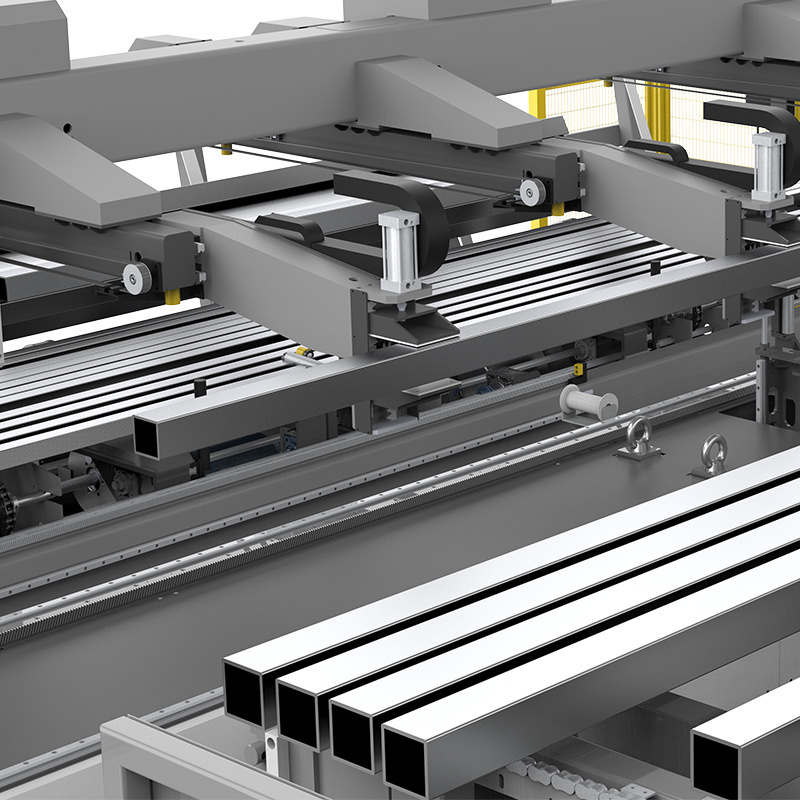

Semi-automatic loading

System

The semi-automatic loading mechanism can realize the semi-automatic loading function of round tubes, square tubes and rectangular tubes.

Machine Bed Design

The machine bed is welded from pipes. It is annealed to eliminate internal stress. After rough machining, vibration aging is performed and then fine machining is performed. This greatly improves the rigidity and stability of the machine tool and ensures the accuracy of the machine tool.

Related Products

Samples & Applications

Customer Service

Hot Searches