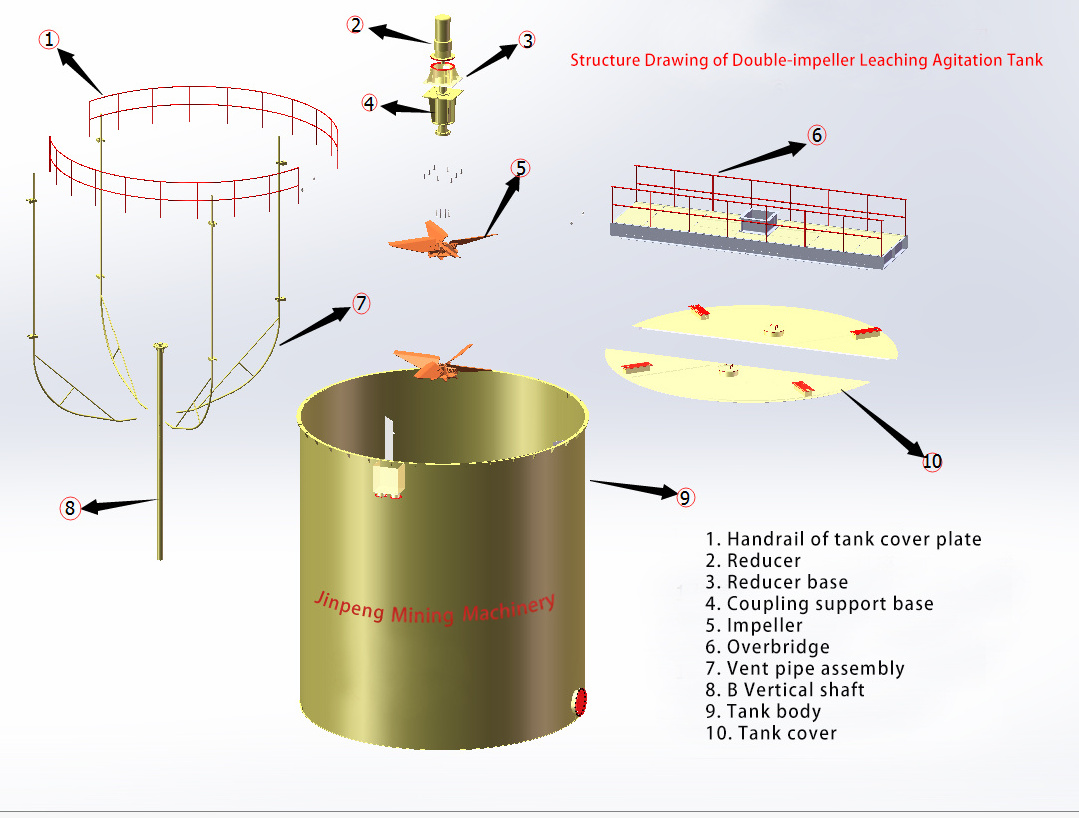

be more uniform, in terms of energy consumption, the more saving energy. the impeller use wrapping adhesive technology, long service life, moral give in to the gas use is for gas, air evenly.

Effective volume : 6-1740m³

|

Model

|

Tank specifications(mm)

D×L

|

Effective volume(m³)

|

Impeller

speed

(r.p.m)

|

Impeller

Diameter

(mm)

|

Motor

model

|

Motor

power

(kw)

|

Tank

Weight

(kg)

|

Total weight (kg)

|

|

SJ2.0×2.5

|

2000×2500

|

6

|

52

|

909

|

XLD2.2-4-29

|

2.2

|

|

2144

|

|

SJ2.5×3.15

|

2500×3150

|

13.14

|

52

|

935

|

XLD2.2-4-29

|

2.2

|

2242

|

3095

|

|

SJ3.0×3.0

|

3000×3000

|

18

|

40.85

|

1130

|

XLD4-5-35

|

4

|

2802

|

4161

|

|

SJ3×3.15

|

3000×3150

|

18.93

|

43

|

1130

|

XLD4-5-35

|

4

|

3331

|

4323

|

|

SJ3.15×3.55

|

3150×3550

|

24

|

43

|

1260

|

XLD4-5-35

|

4

|

3391

|

4583

|

|

SJ3.5×3.5

|

3500×3500

|

30

|

52

|

1310

|

XLD5.5-5-29

|

5.5

|

4286

|

5025

|

|

SJ3.5×4.0

|

3500×4000

|

32.7

|

41

|

1310

|

XLD5.5-5-29

|

5.5

|

4631

|

5429

|

|

SJ3.55×4.0

|

3550×4000

|

33.6

|

43

|

1310

|

XLD4-5-35

|

4

|

4860

|

5825

|

|

SJ3.7×4.2

|

3700×4200

|

38.4

|

42

|

1310

|

XLD4-5-35

|

4

|

5058

|

6153

|

|

SJ4.0×4.0

|

4000×4000

|

38

|

35

|

1750

|

XLD7.5-7-43

|

7.5

|

6056

|

7450

|

|

SJ4.0×4.5

|

4000×4500

|

48

|

35

|

1750

|

XLD7.5-7-43

|

7.5

|

6106

|

7569

|

|

SJ4.5×5.0

|

4500×5000

|

71.57

|

35

|

1750

|

XLD7.5-7-43

|

7.5

|

7506

|

10864

|

|

SJ5.0×5.6

|

5000×5600

|

98

|

31

|

2046

|

XLD11-8-47

|

11

|

10483

|

14291

|

|

SJ5.5×6.0

|

5500×6000

|

112

|

31

|

2100

|

XLD11-8-47

|

11

|

14209

|

18745

|

|

Φ6×6.5

|

6000×6500

|

170

|

24.9

|

2300

|

XLD18.5-9-35

|

18.5

|

16164

|

21006

|

|

Φ6.5×7

|

6500×7000

|

215

|

23

|

2400

|

XLD18.5-9-43

|

22

|

17190

|

25567

|

|

Φ7.0×7.5

|

7000×7500

|

245.4

|

21

|

2400

|

XLD22-10-47

|

22

|

22091

|

30486

|

|

SJ7.5×8.0

|

7500×8000

|

268.6

|

21

|

2900

|

XLD22-10-47

|

22

|

26958

|

34365

|

|

SJ8.0×8.5

|

8000×8500

|

342

|

16.4

|

3200

|

Y250M-8

|

30

|

33489

|

42468

|

|

Φ8.5×9

|

8500×9000

|

395

|

18.5

|

3300

|

Y250M-8

|

30

|

36696

|

46623

|

|

Φ9.5×10

|

9500×10000

|

648

|

16.6

|

3750

|

Y280S-8

|

37

|

46261

|

59786

|

|

Φ10.5×11

|

10500×11000

|

900

|

13.28

|

4400

|

Y315S

|

55

|

56888

|

72647

|

|

Φ11.5×12

|

11500×12000

|

1190

|

12.1

|

4600

|

Y315M-8

|

75

|

67669

|

95669

|

|

Φ12×13

|

12000×13000

|

1414

|

13.4

|

4600

|

Y315L1-8

|

90

|

88418

|

120635

|

|

Φ13×14

|

13000×14000

|

1740

|

10.7

|

5200

|

JR125-8

|

110

|

113669

|

148666

|