A palletizer is a machine that provides automatic means to sort, transfer and stack goods or products onto pallets; usually at the end of a production line. Automatic palletizing facilitates convenient, high-volume shipments. Palletizers provide load stability, precision and operating speed. They can also move more loads at once. The variety of products that palletizers can handle is also increasing, including items such as bottles that would be difficult and uneconomical to palletize by hand.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhenheng

-

Dimension(L*W*H):

-

2000*1000*1800

-

Weight:

-

1500 KG

-

Payload:

-

80 kg to 700 kg (according to customer for selected models)

-

Stacking velocity:

-

10 and 40 cases per minute

-

Using air:

-

6-7 kg

-

Working radius:

-

800 mm - 3150 mm

-

Positioning accruacy:

-

0.2mm

-

Arm Length:

-

2400mm

-

Material:

-

Stainless Steel

-

Packing material:

-

Wooden Case

-

Keywords:

-

Automatic Pallet Stacking Robot

Quick Details

-

Application:

-

Food, Beverage, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, Cigarettes, Tobacco

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood

-

Voltage:

-

380V 50/60HZ

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhenheng

-

Dimension(L*W*H):

-

2000*1000*1800

-

Weight:

-

1500 KG

-

Payload:

-

80 kg to 700 kg (according to customer for selected models)

-

Stacking velocity:

-

10 and 40 cases per minute

-

Using air:

-

6-7 kg

-

Working radius:

-

800 mm - 3150 mm

-

Positioning accruacy:

-

0.2mm

-

Arm Length:

-

2400mm

-

Material:

-

Stainless Steel

-

Packing material:

-

Wooden Case

-

Keywords:

-

Automatic Pallet Stacking Robot

Products Description

Robot Palletizer

Main Features:

1) Simple structure ,easy in installation and maintation.

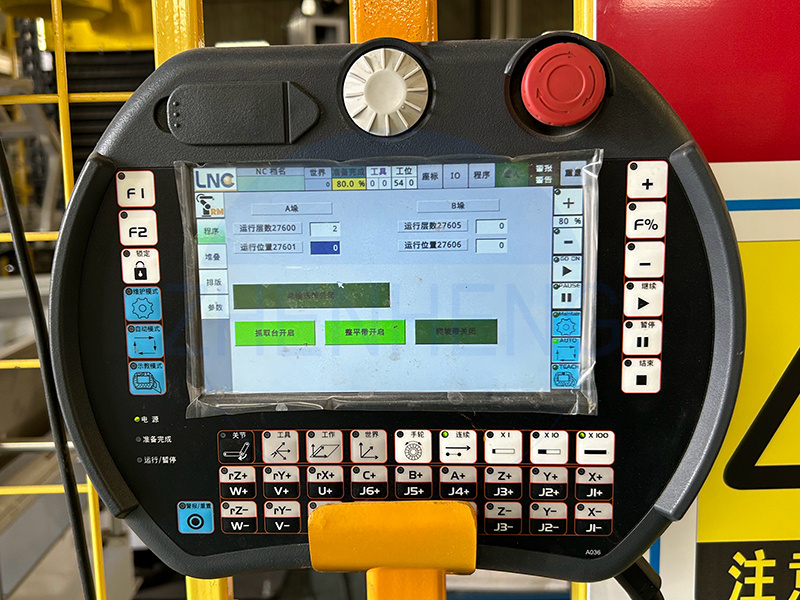

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) When there is some change about the production line, just need to modify the software program.

4) Running in a high automatization and intellectualization,no pollution

5) Robert Palletizer takes less space and more flexiable ,accurate compared to the traditional palletizer.

6) Reducing a lot of labour and labour cost, more productive.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) When there is some change about the production line, just need to modify the software program.

4) Running in a high automatization and intellectualization,no pollution

5) Robert Palletizer takes less space and more flexiable ,accurate compared to the traditional palletizer.

6) Reducing a lot of labour and labour cost, more productive.

Customer Site

Renewable Resources Industry

Refractory Material Industry

Welding Material Industry

Bag Material

Box Material

Building Material

Specification

|

Palletizing Robot

|

4m3

|

|

|

Model

|

ABB/Kuka/Fanuc/Estun/Kawasaki/Cutomized Brand

|

|

|

Palletizing Speed

|

600-1000 times/hour (double gripple available )

|

|

|

Power Supply

|

380v 50/60hz 9kw or as customer's request

|

|

|

Application

|

Forage, flour, fertilizer, grain, box materials, etc

|

|

|

Applicable Packing

|

all kinds of woven bags, paper bags, plastic bags, cartons, etc

|

|

|

Applicable Pallet

|

all kinds of wooden, steel, plastic pallet, etc.

|

|

|

Palletizing Height

|

≤1500mm

|

|

Various styles of mechanical grippers

can flexibly grab boxes, boxes, woven bags, etc. High efficiency, wide application range, low cost, and better completion of palletizing work.

1. A variety of

stack types

can be pre-stored;

2.

The grouping method and number of layers

can be customized;

3.

Multilingual operating system:

Spanish, Arabic, etc

.

1.Rigid arms, light weight, less inertia during fast movements;

2. Unique design enables

four-axis robots

to perform high-speed and high-repetition work

The base is made of high-strength steel with stable structure. High installation accuracy to ensure the positioning accuracy of the robot;

Advantages of Robot palletizer machine:

1.

Increased productivity:

Palletizers eliminate manual labor for unitizing products. They are much more efficient, lift heavier loads, and perform the work faster. They also do not experience exhaustion or injury. With proper maintenance, palletizers can reliably operate 24/7. This reduces any potential bottlenecks in the packaging line.

2.

Better product handling:

Since palletizers are automated machines, their movements are pre-programmed and are designed to function without damaging the product. They do not need to constantly make decisions, unlike their human counterparts. This makes them less prone to errors resulting in better product handling.

3.

Improved workplace safety:

When properly designed, palletizers eliminate workplace threats and hazards associated with manual labor. Manual palletizing poses falling, slipping, tripping, and crushing hazards. They also cause muscle strains due to the repetitive reaching and stacking of products. This can lead to lower back injuries and can permanently damage the health of workers.

4.

Reduced operating costs:

In most applications, particularly in large packaging systems, the cost-benefit analysis of acquiring a palletizer yields positive results. Savings in operating expenses can be derived from increased throughput, low product wastage, and reduced labor costs.

Packing & Shipping

Hot Searches