- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Advantage:

-

Stable Purity

-

Keyword:

-

Nitrogen Production Machine

-

Feature:

-

High-effiency

-

Capacity:

-

High Capacity

-

Application:

-

General Industrial Fields

-

MOQ:

-

1 Set

Quick Details

-

Place of Origin:

-

China

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

1650*1500*2050

-

Marketing Type:

-

Hot Product 2023

-

Advantage:

-

Stable Purity

-

Keyword:

-

Nitrogen Production Machine

-

Feature:

-

High-effiency

-

Capacity:

-

High Capacity

-

Application:

-

General Industrial Fields

-

MOQ:

-

1 Set

Product Overview

Features:

1.Advanced energy-saving inequality pressure equalization structure can improve the utilization rate of adsorbents and directly reduce compressed air consumption.

2.Advanced internal structure ensures uniform distribution of airflow,reduces the impact on the adsorbent,and improves the service life of the adsorbent.

3.In cooperation with well-known molecular sieve manufacturers in China,the most energy-saving and efficient ratio can be selected according to the actual working conditions.

4.Reliable air treatment accessories to ensure the stable operation and service life of the equipment.

5.The blizzard filling method is used to make the adsorbent filling more uniform and dense,and the friction coefficient is reduced to the minimum value, so as to improve the reliability of the long-term operation of the whole machine.

6.Siemens PLC programmable controller is used for automatic control,one-key start does not need special operation,and can reserve the connection with computers,mobile phones and other remote equipment to observe the operation in real time.

7.It adopts the well-known stainless steel pneumatic foot seat valve in China,which has the characteristics of fast opening and closing speed,less energy consumption,good sealing performance,convenient installation and maintenance,and long service life.

8.Adopt unqualified nitrogen automatic emptying device/manual emptying device (optional).

9.Select well-known brand components at home and abroad to ensure the stable operation of the equipment and nitrogen quality.

2.Advanced internal structure ensures uniform distribution of airflow,reduces the impact on the adsorbent,and improves the service life of the adsorbent.

3.In cooperation with well-known molecular sieve manufacturers in China,the most energy-saving and efficient ratio can be selected according to the actual working conditions.

4.Reliable air treatment accessories to ensure the stable operation and service life of the equipment.

5.The blizzard filling method is used to make the adsorbent filling more uniform and dense,and the friction coefficient is reduced to the minimum value, so as to improve the reliability of the long-term operation of the whole machine.

6.Siemens PLC programmable controller is used for automatic control,one-key start does not need special operation,and can reserve the connection with computers,mobile phones and other remote equipment to observe the operation in real time.

7.It adopts the well-known stainless steel pneumatic foot seat valve in China,which has the characteristics of fast opening and closing speed,less energy consumption,good sealing performance,convenient installation and maintenance,and long service life.

8.Adopt unqualified nitrogen automatic emptying device/manual emptying device (optional).

9.Select well-known brand components at home and abroad to ensure the stable operation of the equipment and nitrogen quality.

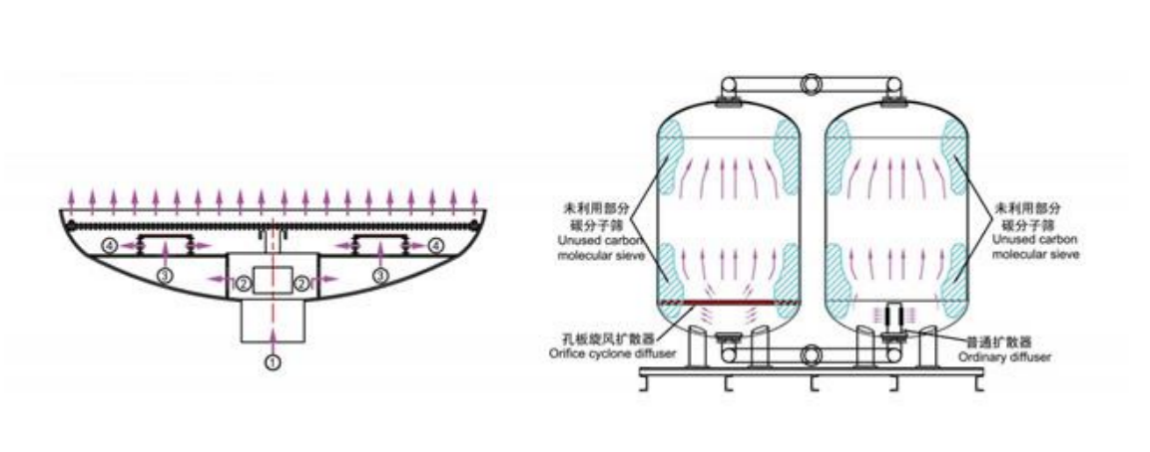

Gas diffusion device:

Original airflow diffuser: The compressed air is forcibly diverted to a surface diffusion mode to avoid the airflow dead angle and tunneling effect, and improve the utilization rate of adsorbent and nitrogen production.

The conventional two gas diffusers are easy to produce dead angles of gas flow, resulting in the inability of the adsorbent to be fully utilized, and it is easy to cause the pulverization and tunneling reaction of the adsorbent, which directly affects the nitrogen quality and the life of the adsorbent.

The conventional two gas diffusers are easy to produce dead angles of gas flow, resulting in the inability of the adsorbent to be fully utilized, and it is easy to cause the pulverization and tunneling reaction of the adsorbent, which directly affects the nitrogen quality and the life of the adsorbent.

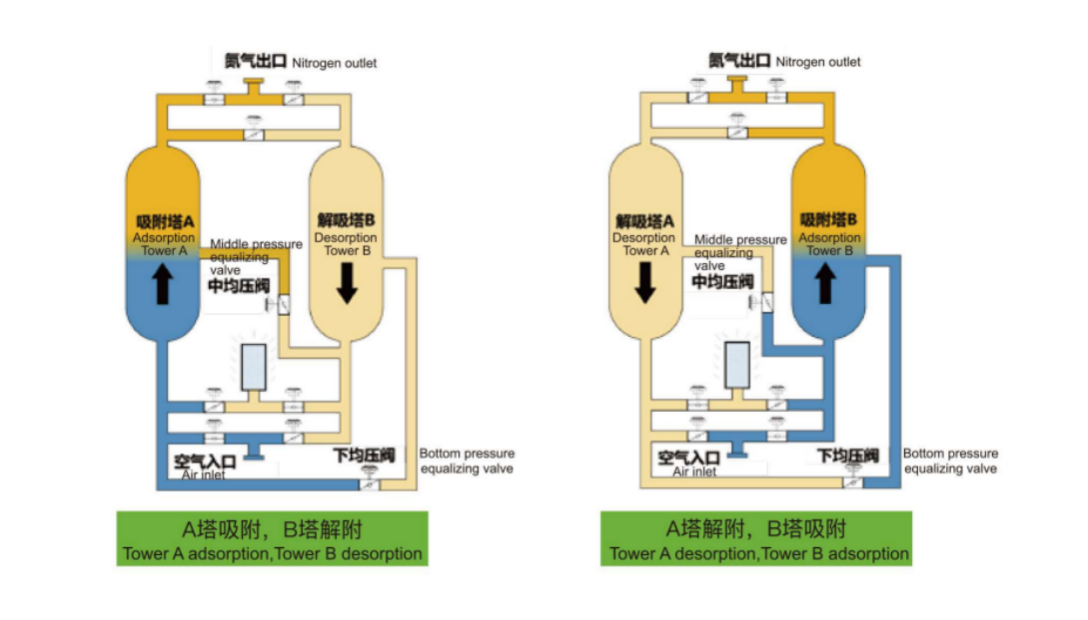

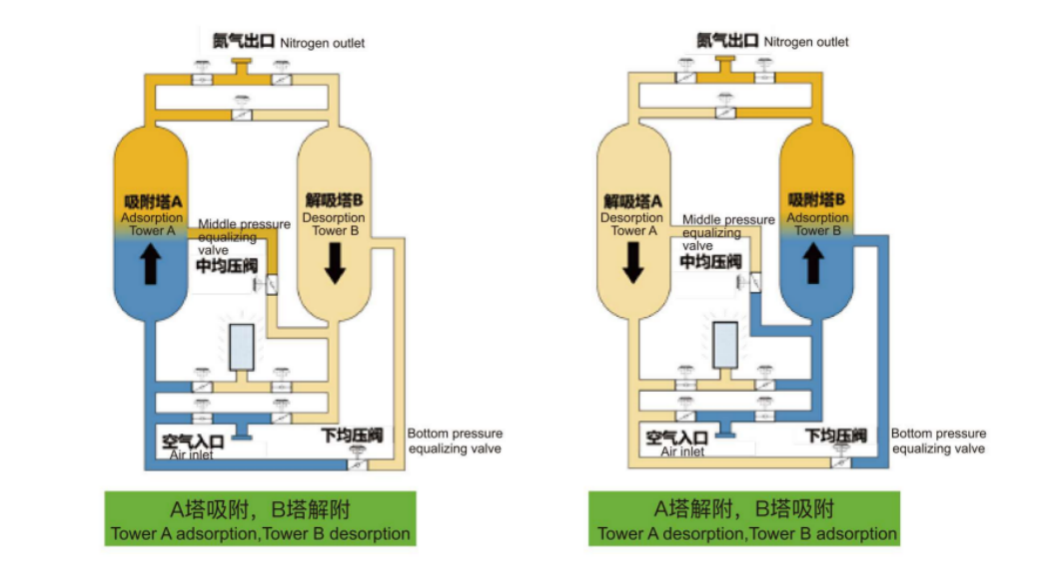

Workflow:

The clean compressed air enters from the bottom of the adsorption tower filled with carbon molecular sieve, and after the air flow diffuses through the equalizer diffuser with a special structure, it evenly enters the adsorption tower for oxygen and nitrogen adsorption separation, and then produces high-purity nitrogen from the top of the adsorption tower and sends it to the nitrogen process tank for storage; A small amount of finished nitrogen enters the regeneration tower to purge the carbon molecular sieve to remove the adsorbed oxygen to achieve regeneration. The two adsorption towers operate alternately in cycles, continuously feeding raw material air to continuously produce nitrogen.

Principle introduction:

PSA nitrogen generator uses air as raw material, carbon molecular sieve as adsorbent, uses the principle of pressure swing adsorption, and uses the method of selective adsorption of oxygen and nitrogen by carbon molecular sieve to separate nitrogen and oxygen, and produces nitrogen automatic equipment.

The carbon molecular sieve is based on the slight difference between the kinetic diameter of O2 and N2 to achieve the separation of nitrogen and oxygen, and the kinetic diameter of the oxygen molecule is smaller, so there is a faster diffusion rate in the micropores of the carbon molecular sieve. The kinetic diameter of the nitrogen molecule is larger, so the diffusion rate is slower, and the final enrichment from the adsorption tower is high-purity nitrogen.

The carbon molecular sieve is based on the slight difference between the kinetic diameter of O2 and N2 to achieve the separation of nitrogen and oxygen, and the kinetic diameter of the oxygen molecule is smaller, so there is a faster diffusion rate in the micropores of the carbon molecular sieve. The kinetic diameter of the nitrogen molecule is larger, so the diffusion rate is slower, and the final enrichment from the adsorption tower is high-purity nitrogen.

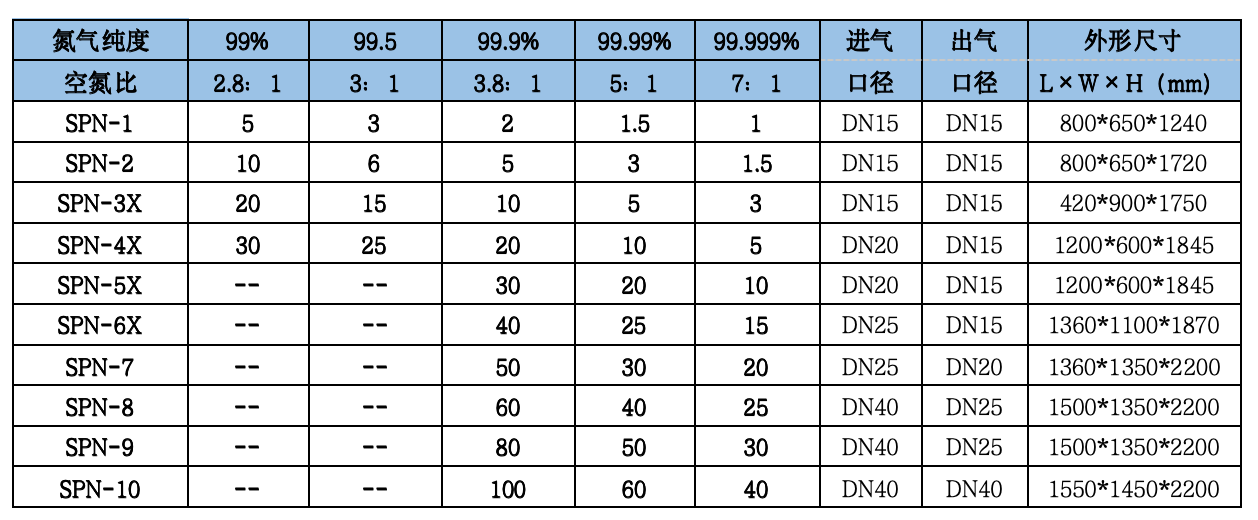

Equipment selection table

Product Advantages:

Automatic start.

Minimum pressure valve and bypass nozzle for quick start.

Avoid excessive gas and carbon molecular sieve damage.

Outstanding reliability.

Rugged design.

Continuous operation (24 hours a day, 7 days a week).

It will not stop operation due to interruption of air supply.

Automatic adjustment, stable purity.

According to the required nitrogen pressure and purity automatically adjusted.

The purity adjustment is extremely convenient.

Failed nitrogen blowing.

Minimum pressure valve and bypass nozzle for quick start.

Avoid excessive gas and carbon molecular sieve damage.

Outstanding reliability.

Rugged design.

Continuous operation (24 hours a day, 7 days a week).

It will not stop operation due to interruption of air supply.

Automatic adjustment, stable purity.

According to the required nitrogen pressure and purity automatically adjusted.

The purity adjustment is extremely convenient.

Failed nitrogen blowing.

FAQ

Q1:Can you supply what is the service?

A1:We can supply the kinds of metal materials and products, and we also can supply other process services.

Q2:What about your the fast lead time if we place order?

A2:It is normal 7-10 days after receive your deposit.

Q3:Which payment terms can you accept?

A3:We can accept the TT,Western Union now or Negotiation.

A1:We can supply the kinds of metal materials and products, and we also can supply other process services.

Q2:What about your the fast lead time if we place order?

A2:It is normal 7-10 days after receive your deposit.

Q3:Which payment terms can you accept?

A3:We can accept the TT,Western Union now or Negotiation.

|

|

Hot Searches