- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

l*2200*2000mm

-

Weight:

-

4000 KG

-

Marketing Type:

-

Hot Product 2024

-

Name:

-

Poultry Carcass Chilling Machine

-

Suit for:

-

Poultry Slaughterhouse Plant

-

Material:

-

304 Stainless Steel

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

mingshun

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

l*2200*2000mm

-

Weight:

-

4000 KG

-

Marketing Type:

-

Hot Product 2024

-

Name:

-

Poultry Carcass Chilling Machine

-

Suit for:

-

Poultry Slaughterhouse Plant

-

Material:

-

304 Stainless Steel

Products Description

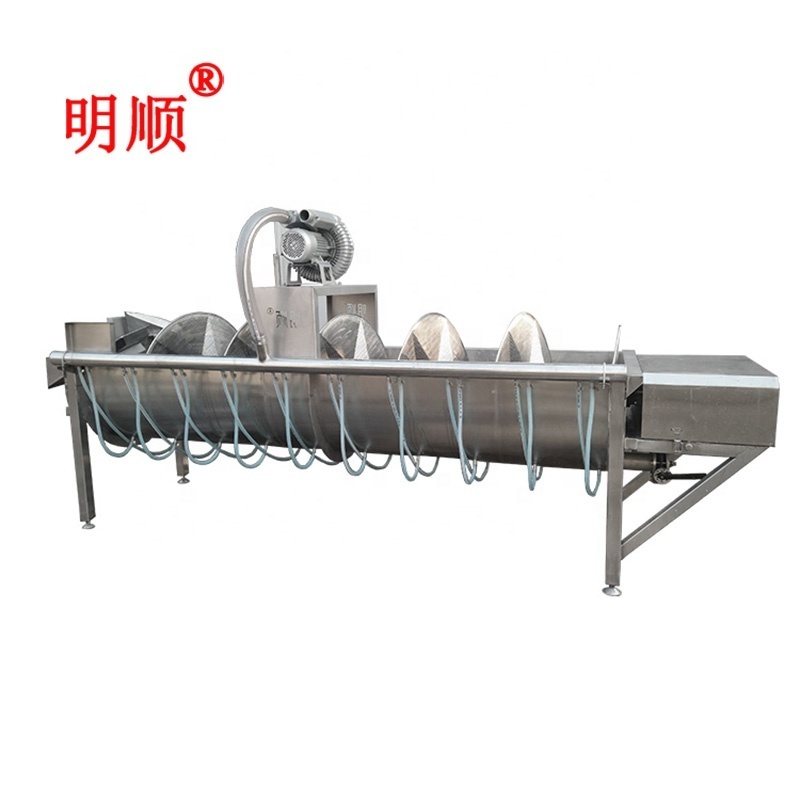

Spiral pre-cooling /pre -chilling machine

Structure Features:

The spiral Pre-cooling machine used for the cooling work of chicken ,duck and goose carcass before segmentation or packing ,in order to achieve the purpose of deacidification ,detoxification ,spiral propulsion system and blower system enables the cooling of chicken carcass more evenly and thoroughly ,Pre-cooling time can be designed according to customer requirements

Technical Parameters:

Cooling time :20-130 min(can be adjustable according to the need of client)

Dimension:L*3600*3600 mm ,L*2700*2800 mm ,L*2200*2000 mm

Power:8-18 kw

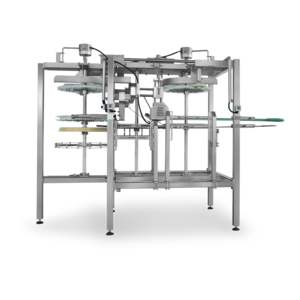

Poultry by product pre-cooling machine

Structure Features:

This machine is mainly sued for poultry by-products pre cooling work ,in order to achieve the purpose of

deacidification ,detoxification ,spiral propulsion system and blower system enables the cooling of chicken carcass more evenly and thoroughly ,Pre-cooling time can be designed according to customer requirements

Technical Parameters:

Cooling time :adjusted according to the requirements

Dimension:L*1200*1050 mm

Power:4.1kw

Cooling time :adjusted according to the requirements

Dimension:L*1200*1050 mm

Power:4.1kw

HALAL POULTRY SLAUGHTER HOUSE MACHINE

We are the manufacturer of poultry slaughter machine,In our company ,we have large size ,medium size ,small size poultry

slaughter machine and a

ccessories for you choose ,the big capacity can reach 13500 chickens per hour ,the full slaughter machine from poultry cage conveyor ,poultry kill ,bleeding ,scalding ,feather removal ,evisceration ,chilling ,carcass cutting ,by -products processing and packing and so on .it's suit for big and small size poultry slaughterhouse and meat company ,which kind of machine do you need ,please feel free to contact with me ,we will design the it as your needs

|

Product Name

|

chicken slaughter line machine

|

|

|

|

|||

|

Main Equipment |

Overhead conveyor line

|

Chicken cage conveyor

|

Stunning Machine

|

Bleeding Trough

|

|||

|

|

Scalding Machine

|

Plucking Machine

|

Evisceration Trough

|

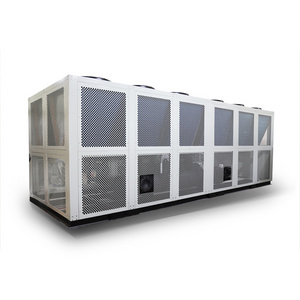

Chilling Tank

|

|||

|

Dimension

|

customized according to the capacity

|

|

|

|

|||

|

Total Power

|

customized according to the capacity

|

|

|

|

|||

|

Voltage

|

380V or customized

|

|

|

|

|||

About the chicken slaughtering line ,there are some question we need to confirm with you ,then we will send you a quotation and design as your need

1. Have you built workshop now? Please e-mail the drawing if you have.

We can make the plan based on the space of your workshop.

If not, we can provide you with a design reference

2. The biggest slaughter capacity per hour you want?

3.What’s the weight of live chicken you slaughtered ?

4. Do you need to cut the heads & feet of chickens?

5.. The chicken heads & feet to eat or make the animal feed or discarded?

6.the chicken viscera (Internal organs) to eat or make the animal feed or discarded

7. what is the final products do you need ? whole chickens,portion parts/split or others' products ?

8. Voltage/frequency also need to be considered. Please reconfirm what's your industrial power supply .is it 380v/50hz/3p or others?

9. Do you need our engineers to supply the professional instruction on site for the equipments installation. any question ,please feel free to contact with me

1. Have you built workshop now? Please e-mail the drawing if you have.

We can make the plan based on the space of your workshop.

If not, we can provide you with a design reference

2. The biggest slaughter capacity per hour you want?

3.What’s the weight of live chicken you slaughtered ?

4. Do you need to cut the heads & feet of chickens?

5.. The chicken heads & feet to eat or make the animal feed or discarded?

6.the chicken viscera (Internal organs) to eat or make the animal feed or discarded

7. what is the final products do you need ? whole chickens,portion parts/split or others' products ?

8. Voltage/frequency also need to be considered. Please reconfirm what's your industrial power supply .is it 380v/50hz/3p or others?

9. Do you need our engineers to supply the professional instruction on site for the equipments installation. any question ,please feel free to contact with me

Details Images

Main Process and Equipment for Chicken Slaughtering Line

1. Chicken Hanging

Hanging the chicken on the slaughtering line by hand

2. Stunning Machine

chicken from dynamic to static to facilitate manual slaughter and bleeding

3. Manual Chicken kill( or Auto Chicken kill )

The chickens are killed manually for bleeding, or automatic killing equipment can be selected as needed.

4.Bleeding Trough

Placed below the slaughter line for easy collection of chicken blood

5. Scalding Machine

Used to scald the carcass of the chicken to remove the feather easily.

6.Plucking Machine(Defeathering Machine)

Used to remove the chicken feathers to get a smooth and good carcass body.

7.Automatic chicken head cutting machine

this equipment use to auto cut the head on production line

8.Automatic chicken feet cutting machine

this equipment use to auto cut the feet on production line

9.Evisceration(Taking Offals)

On the slaughter line, workers will gut the chickens and extract their internal organs during the evisceration process.

10. Pre-chilling machine

Used tocool the temperature of chicken carcasses for deacidification and detoxification

11.Chicken carcass cut-up line

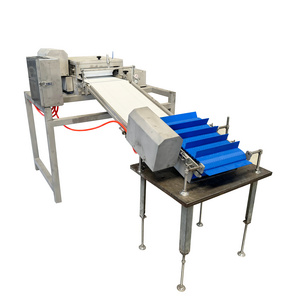

Used to cut the chickens into pieces and blocks, such as wings ,breast ,legs etc.manually on the line.

12. Automatic chicken carcass weight grading machine

Online sorting of chicken products into different groups according to preset weight ranges

13.Chicken packing area

Pack the chickens as actual need , whole chicken or portions packed , by bags, cartons or vacuum machine.

14. Overhead Conveyor Line

Chicken will be processed on this rail, it is main part for the main slaughter plant Production line.

Customer Poultry Slaughterhouse Site

Packaging & Shipping

Hot Searches