1. Low speed, high torque, 8-30 revolutions per minute 2. Low noise and low dust 3. Optional domestic and foreign brand motors and

reducers 4. Based on the different properties of materials, customers can freely choose to equip integral shredding blades or

assembled detachable blades 5. Use advanced simulation software to ensure the mechanical structure of integral or combination

blades and avoid fracture and disassembly 6. Optional hydraulic forced feeding device to quickly shred materials 7. The double

locking structure at both ends of the shaft head ensures the installation position of the blade and prevents axial displacement 8.

Adopting microcomputer (PLC) automatic control, equipped with start, stop, reverse and overload automatic reverse control

functions 9. 80-100 hours of feeding test before leaving the factory to ensure equipment reliability

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

600

-

Voltage:

-

220v/380v/415v, 220V/380V/415V/440V/customized

-

Dimension(L*W*H):

-

2600*1600*2200

-

Year:

-

2024

-

Weight (KG):

-

3800 kg

-

Power (kW):

-

45

-

Application:

-

Recycle Tire

-

Keyword:

-

Double Shaft Shredder

-

Final product:

-

1-10 Cm

-

Usage:

-

Fully Automatic

-

Advantage:

-

Easy Operation

-

Capacity:

-

2-5t/h

-

Suitable material:

-

Waste Plastic Rubber Metal Tire

-

Blades material:

-

H13

-

After-sale Service:

-

Lifelong

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mind

-

Marketing Type:

-

New Product 2024

-

Model Number:

-

600

-

Voltage:

-

220v/380v/415v, 220V/380V/415V/440V/customized

-

Dimension(L*W*H):

-

2600*1600*2200

-

Year:

-

2024

-

Weight (KG):

-

3800 kg

-

Power (kW):

-

45

-

Application:

-

Recycle Tire

-

Keyword:

-

Double Shaft Shredder

-

Final product:

-

1-10 Cm

-

Usage:

-

Fully Automatic

-

Advantage:

-

Easy Operation

-

Capacity:

-

2-5t/h

-

Suitable material:

-

Waste Plastic Rubber Metal Tire

-

Blades material:

-

H13

-

After-sale Service:

-

Lifelong

Product Overview

Performance characteristics of double shaft shredder

1. Double blade shaft mechanism, using multiple multi jaw cutting tools and

coordinating with the tool shaft for multi angle changes, saving cutting effort, strong cutting force, and demonstrating strong crushing ability.

coordinating with the tool shaft for multi angle changes, saving cutting effort, strong cutting force, and demonstrating strong crushing ability.

2. The motor passes through the gearbox transmission system to create a transmission structure, making it

operate at low speed and high torque, achieving a crushing effect. 3. The large transmission wheel is made of special steel and

has undergone heat treatment hardening, resulting in a long service life. 4. The gearbox adopts an oil inlet pulley, which

operates smoothly, has low noise, high torque, and is resistant to long-term operation. 5. The design of low speed and high torque

provides lower noise and less dust, improving a good working environment.

operate at low speed and high torque, achieving a crushing effect. 3. The large transmission wheel is made of special steel and

has undergone heat treatment hardening, resulting in a long service life. 4. The gearbox adopts an oil inlet pulley, which

operates smoothly, has low noise, high torque, and is resistant to long-term operation. 5. The design of low speed and high torque

provides lower noise and less dust, improving a good working environment.

FEATURES AT A GLANCE

Double shaft shredder features:

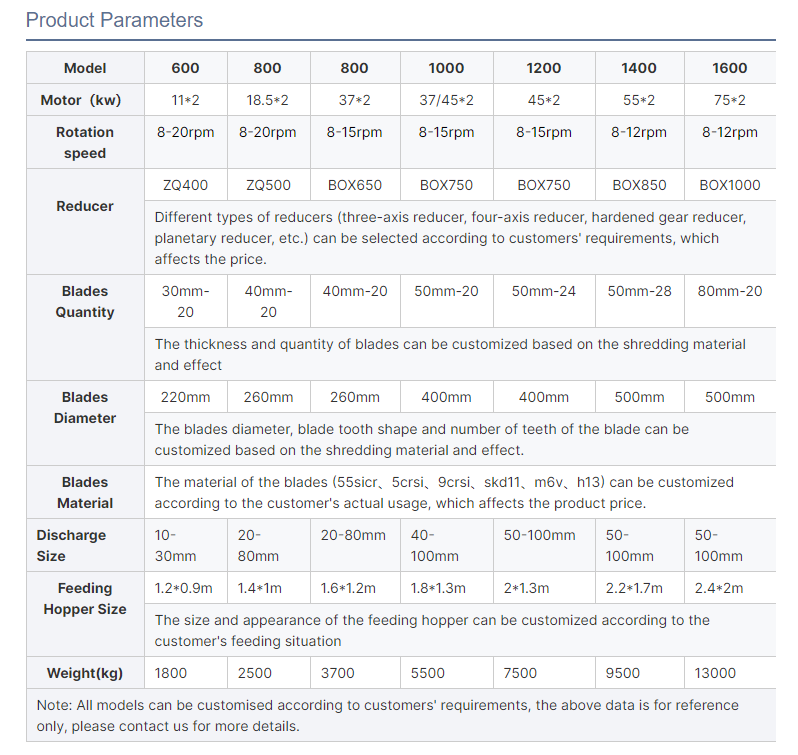

PRODUCT SPECIFICATIONS

|

Model

|

Power(kw)

|

Shredding chamber size

|

Capacity

|

Dimensions

|

Weight

|

|

400

|

7.5*2sets

|

400*360mm

|

500kg/h

|

2000*900*1200mm

|

1500

|

|

600

|

11*2sets

|

600*450mm

|

800kg/h

|

2500*1400*1700mm

|

2200kg

|

|

800

|

18.5*2sets

|

800*560mm

|

1000kg/h

|

3500*1700*2200mm

|

3000kg

|

|

1000

|

30*2sets

|

1000*650mm

|

1500kg/h

|

3800*1800*2200mm

|

4000kg

|

|

1200

|

45*2sets

|

1200*780mm

|

2000kg/h

|

4200*2000*2200mm

|

4500kg

|

|

1400

|

75*2sets

|

1400*860mm

|

3000kg/h

|

4500*2100*2200mm

|

5000kg

|

|

1600

|

90*2sets

|

1600*950mm

|

5000kg/h

|

4700*2200*2300mm

|

6000kg

|

|

1800

|

110*2sets

|

1800*1100mm

|

7000kg/h

|

5600*2300*2300mm

|

6500kg

|

We can customize the machine to the size you need !

PRODUCT DETAILS

SALES AND SERVICE NETWORK

Project in Thailand

Project in India

Project in Russia

Packaging

Certifications

FAQ

1. Are you a manufacturer, trading company or a third party?

We are a manufacturer. Our factory is in Zhengzhou.

2. How can I get to your factory?

When you arrive at Zhengzhou high-speed Railway Station or the airport, we can pick you up at the airport.

3. Could you help me book a hotel if I need to stay with you for a few days?

It's my pleasure. We have hotel reservation service here.

4. What is your minimum order quantity? Can you send the sample to me?

Our MOQ is 1 set, because our products are mechanical equipment, it is difficult to send samples to you, but we can send you the catalog, warmly welcome you to visit our company.

5. What is the quality level of your products?

At present, it has passed CE, ISO, SGS, TUV, SONCAP and other certifications.

6. When is the delivery time for your machines?

Under normal circumstances, our machine delivery time is around 15-20 days, customized machines will be delivered after consultation with the customer.

7. Can the machine be customized according to our needs, such as pasting our logo?

Of course, our machines can be customized according to your needs, and can also be affixed with your logo.

8. About after-sales service, how do you solve the problems of overseas customers in a timely manner?

The warranty period of our machines is usually 12 months, during which time we will immediately arrange international Courier to ensure that the replacement parts can be delivered as soon as possible.

9. After we place the order, will you arrange to install the machine now?

All machines are well tested before delivery, so most of them can be used directly, and our machines are easy to install, if your customers need our help, we will be happy to arrange installation, but all costs will be borne by you.

Hot Searches