Name: Carbonization pipes

Brand: Mingyang

heat resistance thermal steel materials

The

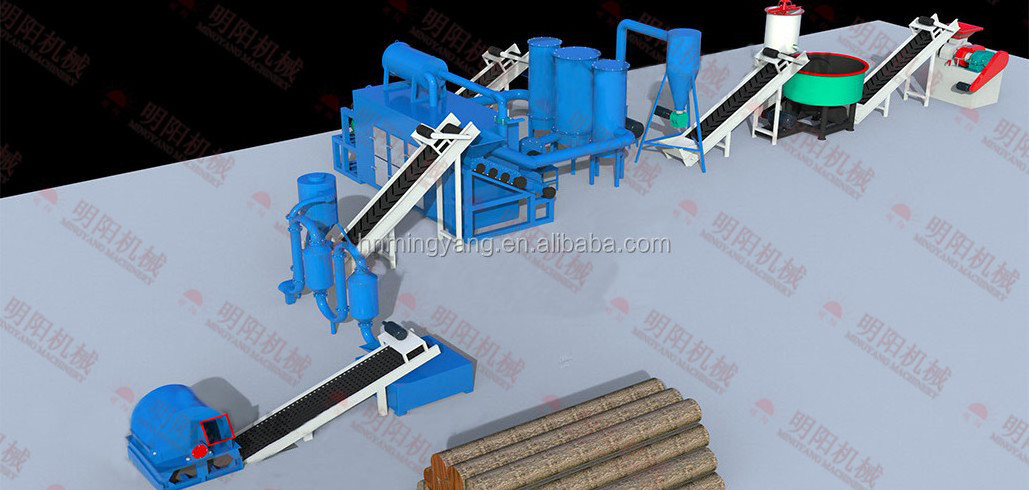

sawdust charcoal kiln

is an advanced technology type carbonizing machine which can feed raw materials and produce finished charcoal at the same time. It is an external heated drying and internal carbonizing machine. The whole production process does not produce harmful gas neither smoke emission.It produces charcoal directly from Peanut shells, sawdust, corn stalk, bagasse, branches, rice husk, bamboo shavings, sorghum stalk, sunflower seed shell, lees, corn cobs, coconut, coffee grounds, cotton pole, bean pole, dead leaves, sweet potatoes, grass biomass raw materials, waste residues, medical pharmaceutical companies sludge, and other materials with size less than 50 mm. This is the best choice of waste agriculture recycling as well as an efficient way to reduce the tension of supply and demand of resources in our country.

Charcoal is a kind of renewable energy fuel that can be recycled from biomass waste. Its calorific value is higher than that of similar raw materials, and it burns better than ordinary coal.It can absorb toxic gases, such as methanol generated after decoration;When burning smokeless, tasteless, non-toxic, clean and sanitary, has the broad market potential, easy to sell, quick effect, large use, large market demand.

|

The Main Parameters

|

|

|

|

|

||||

|

Model

|

capacity

|

Max temperature

|

Machine Auxiliaries

|

|

THJ 200

|

130-220kg/h

|

400-500 degree

|

Screw feeder, dust collector,condenser,tar separator, draught fan,

|

Biomass particles no more than 50mm and moisture content less than 20% can be directly carbonized into this sawdust charcoal kiln , for example: sawdust, rice husk, fruit husk, palm husk, peanut husk, bamboo shavings, shavings and so on can be directly carbonized;Raw materials with large size (above 50mm), such as branches, bark, coconut shell, straw, hemp stalk and tobacco stalk, need to be crushed firstly.If the moisture content is more than 20%, we need to choose a dryer to cooperate with the production process.

1,Mechanical transmission parts have sharply reduced the power consumption, a more reasonable design, reduce the failure rate more than 80%;

2,The feed size of the host machine increases by more than 20-30mm.

3,Screw conveyor inside of the stove, making the carbonized materials moving regularly, at the same time the output and carbonizing uniformity and quality have been greatly improved.

Name: Carbonization pipes

Brand: Mingyang

heat resistance thermal steel materials

Brand: Mingyang

Special structure of the tank make cooling of the burning smoke from the furnace inside and filter some of the wood tar .

Name: Independent controller

Brand: Mingyang

(1) CE motor with national standard reducer

(2) Separately control the temperature

(3) Adjust the heating, keep the carbonization efficiently

Name: Bio-gas purification system

Brand: Mingyang

heat resistance thermal steel materials,

new type, seprately independently water spraying and pipe cooling tanks, after this purification, there is no smoke and harmful elements emission. Can meet the local environmental protection regulations.

Name: Discharge cooling conveyor

Brand: Mingyang

Doubel layer with cooling water inside

Name: Gear and chain transmission

Brand: Mingyang

(1)Gear and chains transmit the speed to the carbonizing pipes.

(2) More stable and reliable

(3) Less daily maintenance work

Name: Draught fan

Brand: Mingyang

Stainless steel blades fan high temperature and corrosion resistant.

Name: Combustible gas recycling pipe and valves

Brand: Mingyang

(1)Gear and chains transmit the speed to the carbonizing pipes.

(2) More stable and reliable

(3) Less daily maintenance work

Gongyi Xiaoyi Mingyang Machinery Plant is one of the largest and earliest manufacturers of the biomass energy equipment ( sawdust charcoal kiln , biomass briquette machine line, charcoal making production line, wood pellet production line and the related machinery) for over 30 years. Now it has been an efficient group with more than 120 experienced workers. having a over 12000 square meter high level standard workshop with advanced producing equipment, Experienced technicians. We can produced 6 production line, more than 150 kinds of machines, awarded 10 patents in China.

a. Sales team will suggest suitable project.

b. Technical team analyse and design special molds for you.

c. Pick you up at airport, arrange hotel-booking.

d. Other travel arrangements.

a. Assist you build up factory and production line.

b. Install and maintain machines.

c. Training your workers to achieve skillful operation.

d. Offer technical support through telephone or online videos at any time.