- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Jiangzhi

-

Model Number:

-

OEM

-

Item:

-

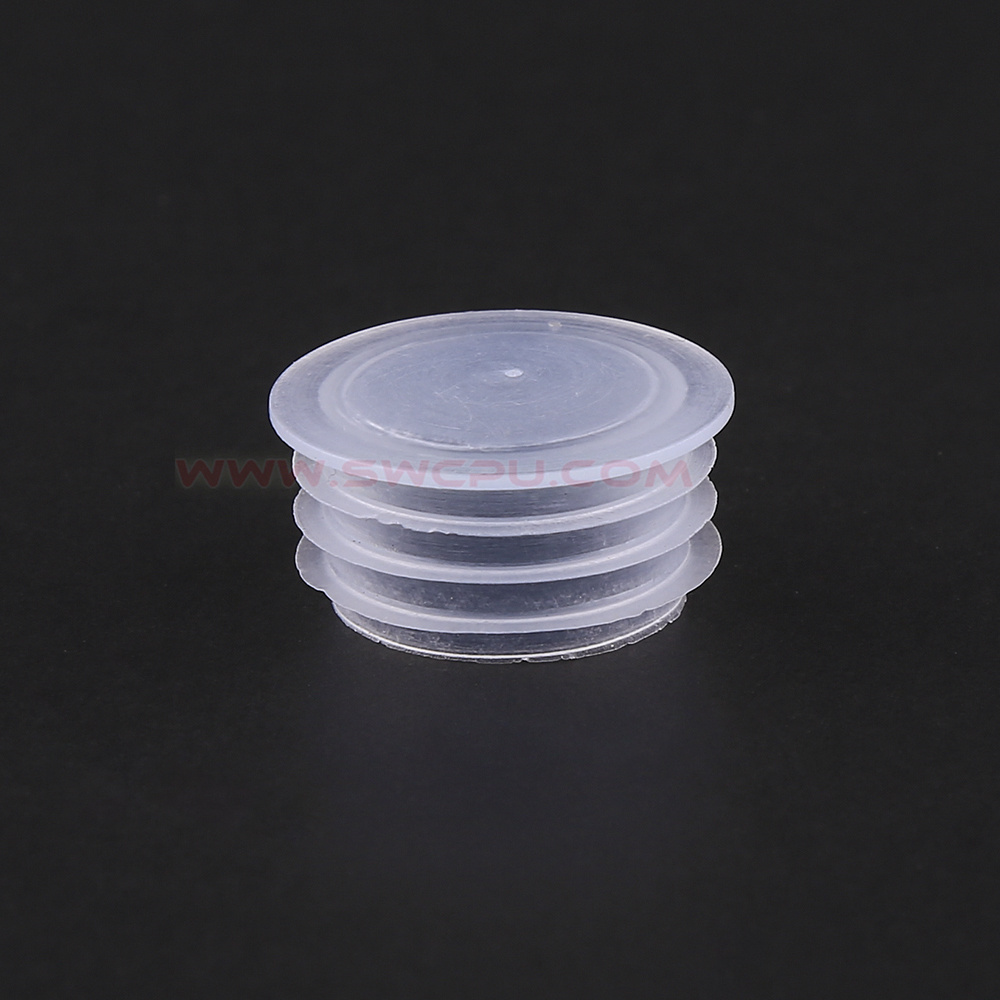

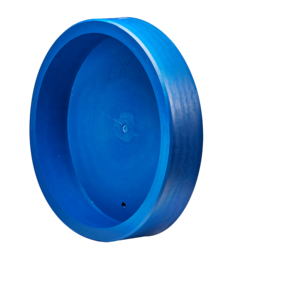

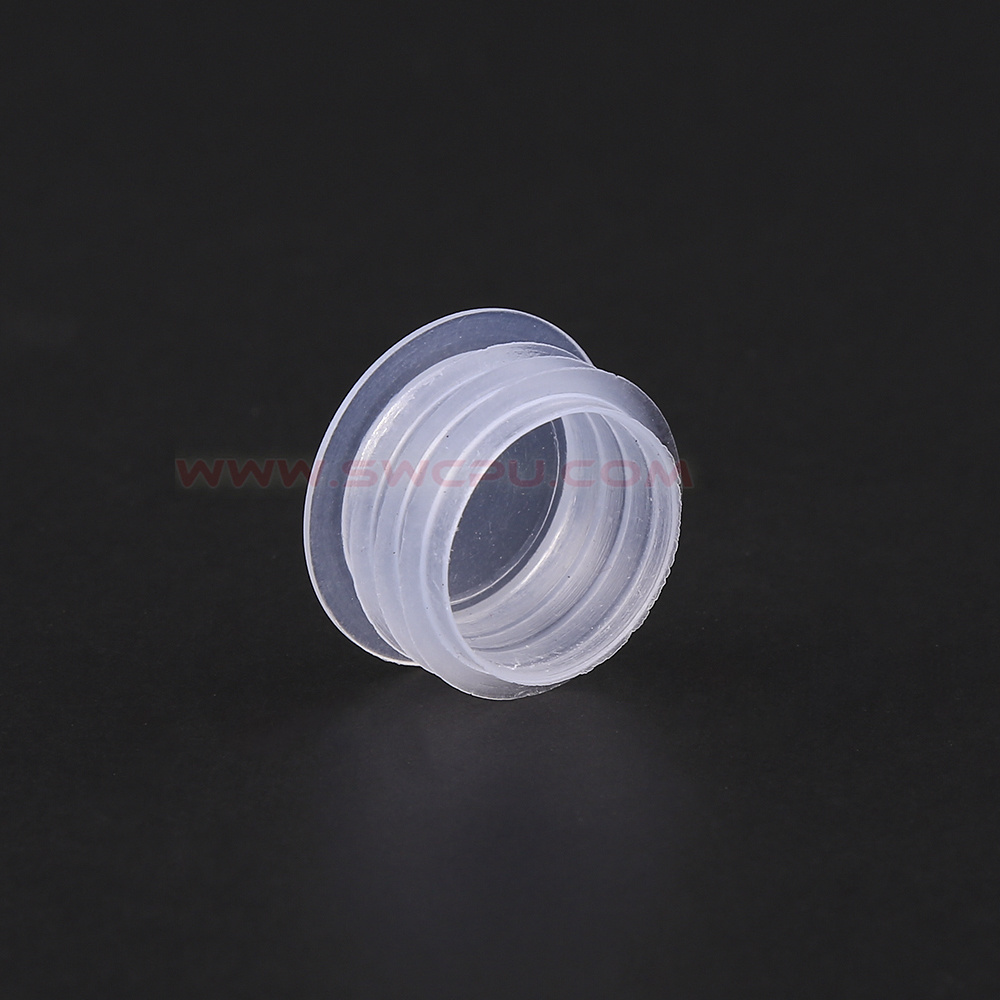

Customized pipe threaded plastic end cap

-

Material:

-

PA, ABS, POM, PP, PTFE, PE, PVC, TPU, etc, or any compound plastic

-

Size:

-

As per customer's requirements

-

Color:

-

Black,white,red,green,transparent or any color

-

Tolerance:

-

±0.05mm

-

Technology:

-

Hot pressing molding ,injection molding or extrusion

-

Working temperature:

-

-60~350℃

-

Density:

-

1.0-2.0g/cm3

-

Drawing Format:

-

DWG/DXF/IGS/STEP/X-T and PDF

-

Service:

-

OEM or ODM

Quick Details

-

Technics:

-

Other

-

Shape:

-

Equal

-

Head Code:

-

Square

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Jiangzhi

-

Model Number:

-

OEM

-

Item:

-

Customized pipe threaded plastic end cap

-

Material:

-

PA, ABS, POM, PP, PTFE, PE, PVC, TPU, etc, or any compound plastic

-

Size:

-

As per customer's requirements

-

Color:

-

Black,white,red,green,transparent or any color

-

Tolerance:

-

±0.05mm

-

Technology:

-

Hot pressing molding ,injection molding or extrusion

-

Working temperature:

-

-60~350℃

-

Density:

-

1.0-2.0g/cm3

-

Drawing Format:

-

DWG/DXF/IGS/STEP/X-T and PDF

-

Service:

-

OEM or ODM

Product Description

Plastic end caps are great for finishing off edges on gate post, Tennis Racquet Butt cap Round Tubing, steel tube, rail,furniture etc.The plastic inserts are perfect for preventing unwanted marks and scratches on your floor surfaces.

Our plastic tube inserts can prevent dirt and dust gathering inside the tube and causing rust. Made from extra strong plastic, our caps are weather resistant offering durability in unpredictable weather conditions.

|

We Support Parts Customization for Most Plastic Materials

(Non-Standard Parts)

|

|

|

|

|

||||

|

Product info

|

|

|

|

|

||||

|

Material

|

PA, PP, ABS, POM, PVC, HDPE, UHMWPE. etc, or any custom compound

|

|

|

|

||||

|

Size

|

As per customers' requirment

|

|

|

|

||||

|

Color

|

Any color or according to Pantone colors

|

|

|

|

||||

|

Service

|

OEM or ODM

|

|

|

|

||||

|

Samples

|

1-2pcs of free samples are available

|

|

|

|

||||

|

Production basis

|

Product drawing, 3D files or exsiting samples

|

|

|

|

||||

|

Process Technic

|

Injection molding, CNC machining, extrusion, casting, etc.

|

Injection molding, CNC machining, compression molding, extrusion, casting, stamping, etc.

|

|

|

||||

|

Tolerance

|

±0.05mm

|

|

|

|

||||

|

Lead Time

|

7-15 days for molding, 10-15days for mass production

|

|

|

|

||||

|

Application

|

Automotive, Mechanical equipment, Construction, Home application, Aviation, Office facilities, etc.

|

|

|

|

||||

|

Shipping & Payment

|

|

|

|

|

||||

|

Packaging

|

Ziplock bag or bubble film plus cardboard boxes with wooden pallets outside

|

|

|

|

||||

|

Shipping Method

|

Sea, Air, DHL, TNT, Fedex, UPS, etc.

|

|

|

|

||||

|

Payment Terms

|

Trade assurance, T/T, L/C, Western Union

|

|

|

|

||||

|

|

|

|

|

|||||

Available in following material

(Any custom compound plastic is available )

(Any custom compound plastic is available )

* PA6 PA66 PA6+GF PA66+GF

* PE, LDPE, HDPE, UHMWPE

* ABS * POM

* PP * PTFE

* PVC * PEEK

* ABS * POM

* PP * PTFE

* PVC * PEEK

* PC

*

PMMA

* PS

*

PPS

* PET * PBT

* PET * PBT

*

AS

*

TPV

* TPU

*

TPE

Production Process

Why Choose Us

Hebei Jiangzhi Machinery Equipment Co., ltd

is a global manufacturer for molds and custom parts and components. Our capabilities includes

mold making

,

injection molding

,

compression molding,

CNC machining

,

metal stamping

,

parts assembly

. Our products material range from plastic, rubber to metal, covering industries such as automotive, agriculture, food&beverage, consumer electronics, medical equipment, etc.

Following pictures are taken in our own factory.

Mold Shelf

Mold Material

Vulcanizing

Injection

Machine

Warehouse

Certified By SGS & ISO9001;2005

FAQ

Q1.

Are you manufacture or trade company?

A: We are manufacture.

Q2.

What kind of payment do you accept?

A: Trade assurance, T/T, L/C, Weston Union are all accepted.

Q3.

What is normal lead time?

A: Average 15-25days for tooling, bulk orders should be depends on quantity.

Q4

. What is your standard package?

A: In general we use ziplock bag or bubble film plus cardboard boxes, wooden pallets or wooden cased will be used if necessary. Special packing method is available if needed.

Q5.

What is the working life of the mould?

A: It depends on the parts we made. Besides, we will maintain or replace the mould by ourselves.

Q6

. How many employees do you have?

A: We have 150 employees for factory, 45 employees for sales, 16 employees for technical support.

Hot Searches