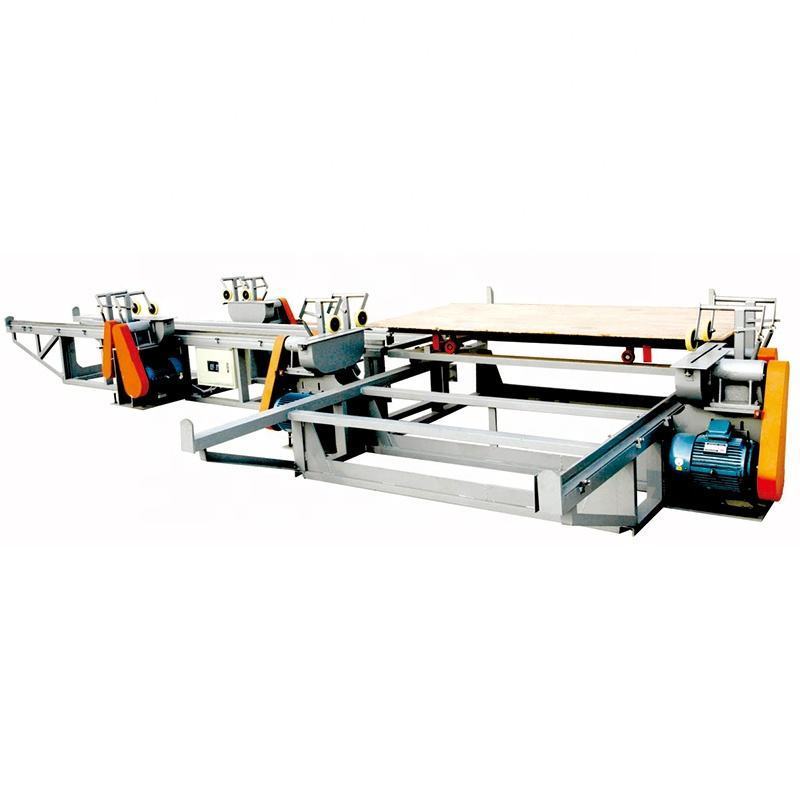

1.The automatic four-side sawing machine is suitable for trimming various special-shaped boards such as blockboards, multi-layer boards, ecological boards, building templates, insulation boards, container bottom boards, and floor substrates.

2. It can also improve the sawing accuracy and quality of the boards, and increase output of finished product.