- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

400

-

Name:

-

crush metal machine

-

Application:

-

Copper Wire Recycling

-

Raw material:

-

Used Metal Material

-

Final product:

-

Metal Granule

-

Machine Type:

-

Support Customization

-

Advantage:

-

High Efficiency Low Energy Consumption

-

Capacity:

-

800-5000kg/h

-

Certification:

-

CE ISO

-

VOLTAGE:

-

380V 50Hz 3Phase/Customized

-

Shredder Type`:

-

Vertical Shredder

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Quality Machine

-

Power (kW):

-

7.5

-

Weight (KG):

-

400

-

Name:

-

crush metal machine

-

Application:

-

Copper Wire Recycling

-

Raw material:

-

Used Metal Material

-

Final product:

-

Metal Granule

-

Machine Type:

-

Support Customization

-

Advantage:

-

High Efficiency Low Energy Consumption

-

Capacity:

-

800-5000kg/h

-

Certification:

-

CE ISO

-

VOLTAGE:

-

380V 50Hz 3Phase/Customized

-

Shredder Type`:

-

Vertical Shredder

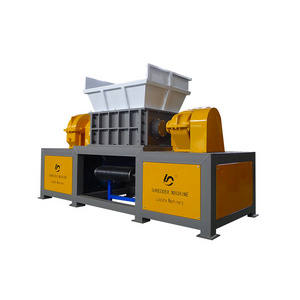

Product Overview

Metal Crushing Machine

Shredder, also known as shearing shredder, reduces the size of materials by cutting, tearing and squeezing. Shredders are used in metal products such as scrap steel, scrap iron, radiators, waste plastics, waste rubber, wood, Crop straw and other large-volume wastes are improved and produced according to the actual domestic situation, and a new series of shredders are launched, which provides a guarantee for our waste recycling and volume reduction treatment.

FEATURES AT A GLANCE

The working principle of metal crusher:

1. The metal crusher is mainly composed of feeding silo, crushing double stick, power distribution control system, discharge

conveyor and power drive;

2. Feeding silo: place the metal to be broken to prevent the metal from splashing out and causing

accidents when broken;

3. Crushing double rollers: The double rollers are equipped with wear-resistant knives. After all the

cutter discs are assembled, a spiral cutter is formed. After rotation, each cutter disc is guaranteed to be evenly stressed, and

the double rollers are buckled to ensure that there is no large gap between the double-roller cutter discs. , through the hook of

the knife and the extrusion between the double sticks to achieve the crushing of the material;

cutter discs are assembled, a spiral cutter is formed. After rotation, each cutter disc is guaranteed to be evenly stressed, and

the double rollers are buckled to ensure that there is no large gap between the double-roller cutter discs. , through the hook of

the knife and the extrusion between the double sticks to achieve the crushing of the material;

4. The power system of the metal crusher: the feed is driven by a reducer;

5. Discharge conveyor: independent power system, the whole is fixed on the crusher with bolts, which can be extracted as a whole, and the maintenance and replacement parts are flexible and convenient;

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Host base

|

Channel steel production

|

|

2

|

External dimensions

|

Length 2400*width 1550*height 3250

|

|

3

|

main rotor disc

|

4 (thickened steel material)

|

|

4

|

hammer

|

24 (Menggan steel material)

|

|

5

|

Screen thickness

|

50mm

|

|

6

|

Motor base

|

Channel steel production (thickening)

|

|

7

|

Feed conveyor

|

700*7M

|

|

8

|

Outlet conveyor

|

700*4M

|

|

9

|

Magnetic Separation Conveyor

|

700*3M

|

|

10

|

Distribution Cabinet

|

star delta start

|

|

11

|

counterweight wheel

|

75KG

|

Final product

Hot Searches