- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Disc Dia.:

-

Optional

-

No Load Speed:

-

0.25~0.3m/s

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Xinghuo

-

Model Number:

-

X-600

-

Warranty:

-

1 year warranty

-

Usage:

-

Car Baking

-

Certification:

-

ce

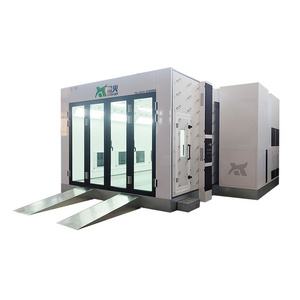

Quick Details

-

Power:

-

16-42KW

-

External Size:

-

7000*5300*3300

-

Internal Size:

-

6900*3900*2600

-

Voltage:

-

380V/50HZ

-

Disc Dia.:

-

Optional

-

No Load Speed:

-

0.25~0.3m/s

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Xinghuo

-

Model Number:

-

X-600

-

Warranty:

-

1 year warranty

-

Usage:

-

Car Baking

-

Certification:

-

ce

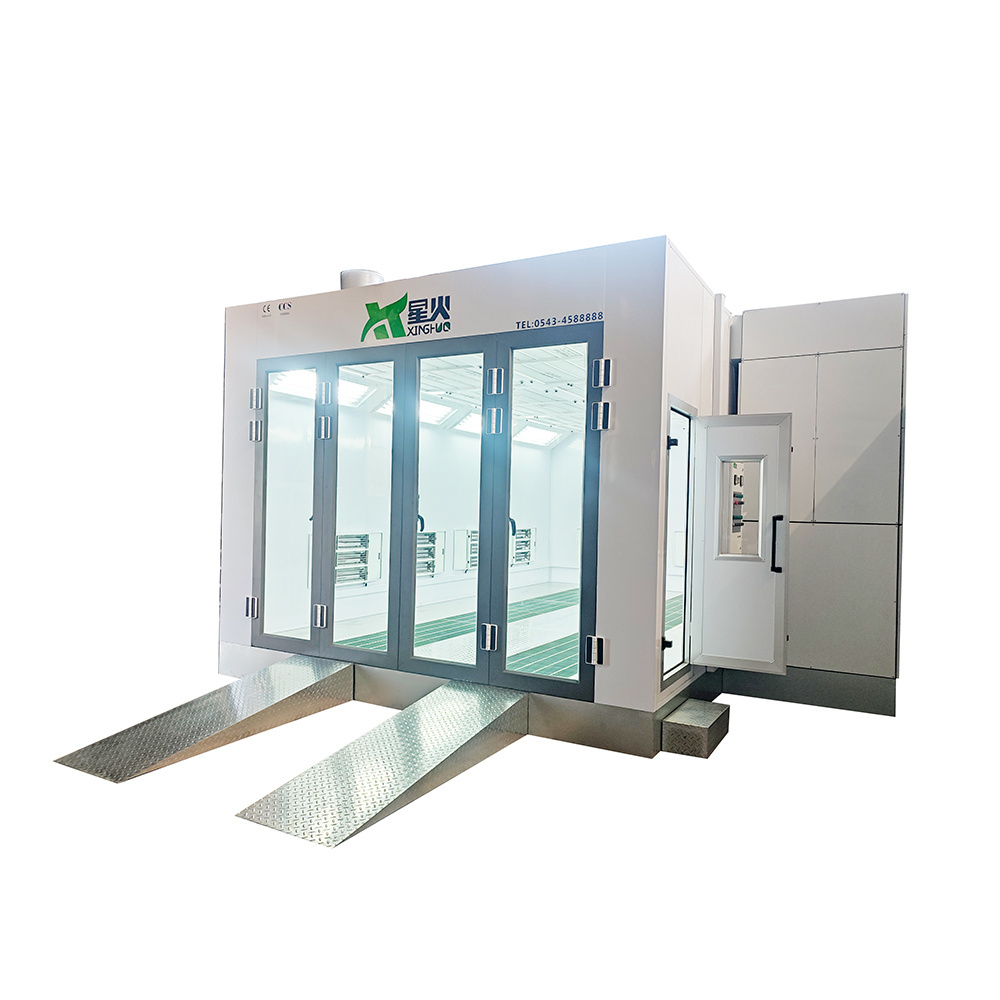

Specification

|

No.

|

Project

|

Unit

|

Specification

|

*

|

|

1

|

Spray booth type

|

*

|

Side-inlet, side-exhaust spray booth

|

Single station

|

|

2

|

Inside diameter of the chamber

|

mm

|

6900×3900×2800

|

*

|

|

3

|

The outer diameter of the chamber

|

mm

|

7000×4000(+1300)×3500

|

Including 300mm base

|

|

4

|

Door opening size (W×H)

|

mm

|

3200×2600

|

4 sheet metal gates

|

|

5

|

Noise when the equipment is working

|

dB

|

≤85

|

*

|

|

6

|

Indoor illumination

|

Lux

|

≥1000

|

*

|

|

7

|

Average indoor wind speed

|

m/s

|

≥0.3

|

*

|

|

8

|

Air supply filter

|

*

|

tertiary filtration

|

*

|

|

9

|

Paint mist treatment efficiency

|

*

|

≥98%

|

*

|

|

10

|

Paint temperature

|

℃

|

60-80

|

*

|

|

11

|

Total enter air volume

|

m³/h

|

25000

|

2 sets of 4kw intake fans

|

|

12

|

Total exhaust air volume

|

m³/h

|

20000

|

1 set 7.5kw exhaust fan

|

Products Detail

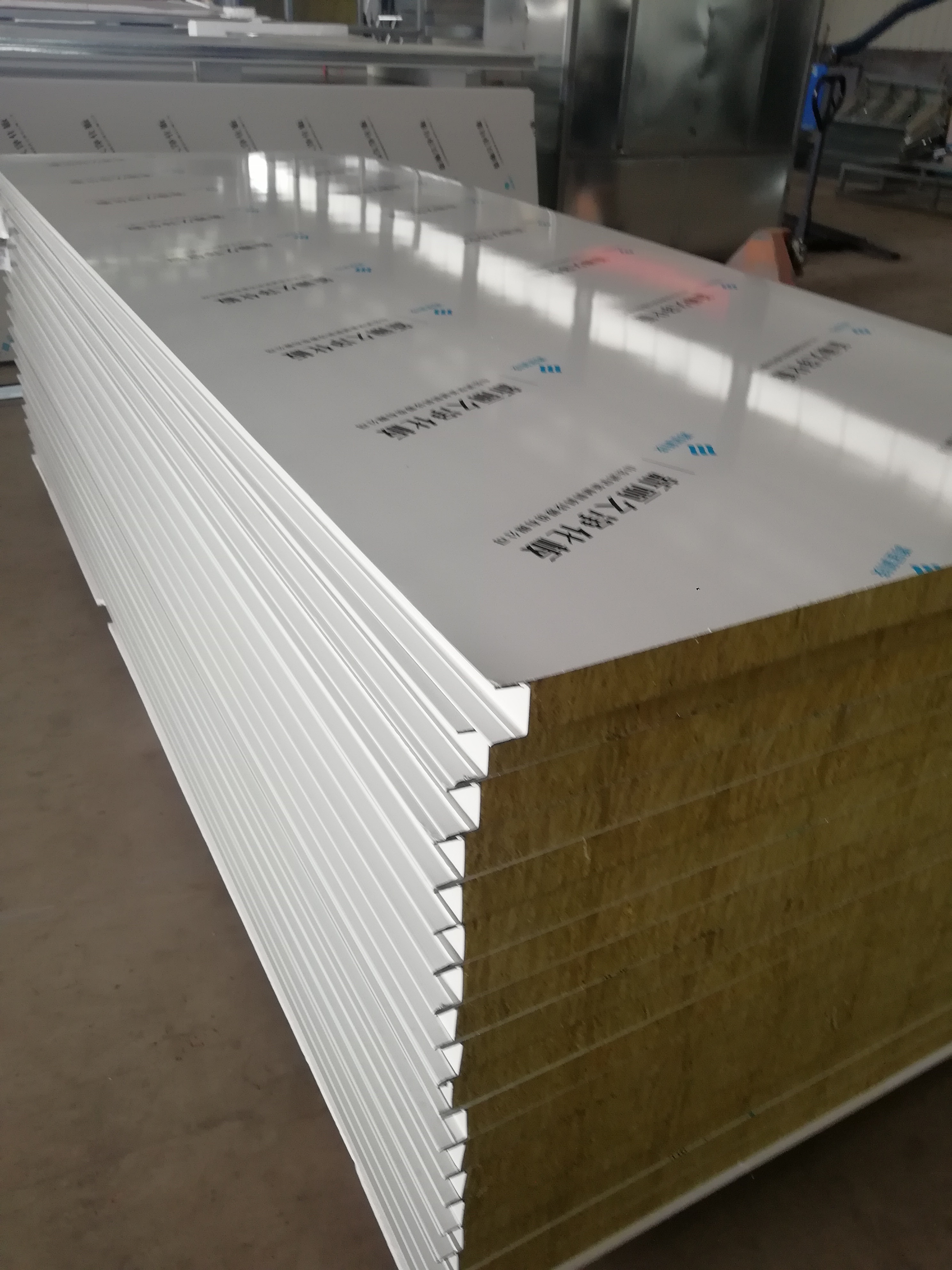

House System

①The wall panel of the house is made of 50mm industrial purification fireproof rock wool board, the thickness of the thermal insulation board is 50mm, the single-layer color steel plate δ0.5mm, and the rock wool bulk density is 120 kg/cubic;

②The top is bent and buckled with δ0.6mm galvanized sheet, and the top frame is welded with 40*60 square tube, which is firm and safe.

③The slot and wrap angle are bent with δ0.8mm galvanized sheet and sprayed with plastic.

Plenum system

①The top "T" beam is welded with 40*60mm galvanized square tube, and both ends are equipped with 2.0mm galvanized sheet folded 90°, and the connection with the paint room is lap joint;

②The top vertical bracing is made of 40*60mm galvanized square tube, and the two sides of the square tube are equipped with connecting rows. The fixing method is screw connection, which has high stability and is used to support the top plate;

③The upper sealing plate is made of δ0.8mm galvanized sheet by bending and welding, sprayed with plastic, and the color is white; the connection between the upper sealing plates is screw connection, and the connection between the upper sealing plate and the top beam is screw Connection, large bearing capacity and strong stability.

④ The filter frame material is made of high-quality profiles to be folded into a "concave" shape, sprayed with plastic, and the filter cotton edge can be inserted into the frame to prevent lint. The design of 6 cotton supports is convenient for replacement and enhances the overall strength.

Gate system

①The gate design is a folding four-leaf tempered explosion-proof sheet metal large glass door, all handmade, with a built-in δ1.2mm high-strength skeleton, a built-in mortise lock, and a glass observation window, which is convenient for observing the paint spraying in the room; the size of the door opening is W :3200mm×H:2600mm, the size of single door is W:800mm×H:2600mm;

Gate system

②There is a safety working door on one side of the room, equipped with a safety pressure lock device. When the pressure in the room reaches the limit, the safety door will automatically pop open to release the pressure, which is convenient and safe. It is equipped with a glass observation window, which is convenient for observing the paint spraying in the room. The size of the door opening is: W:650mm×H:1800mm.

lighting device

①The light box is folded and sprayed with high-quality δ1.2mm galvanized steel sheet, and the lighting tubes are all 16W Philips LED integrated tubes, with high lighting brightness;

②The ceiling lamp is equipped with 8 groups, each group of 4 lamps, to achieve no ghosting and blind spots in the working area;

③The surface of the lamp tube has a glass cover, and the frame is sprayed with plastic, which can prevent rust and be beautiful; the light boxes are evenly distributed on both sides of the spray booth and hang on the top of the spray booth at a 45-degree angle.

④The waist light is equipped with 9 groups of LED panel lights to increase the overall brightness and achieve illuminance of 1000 lux;

④Lighting power: 2KW.

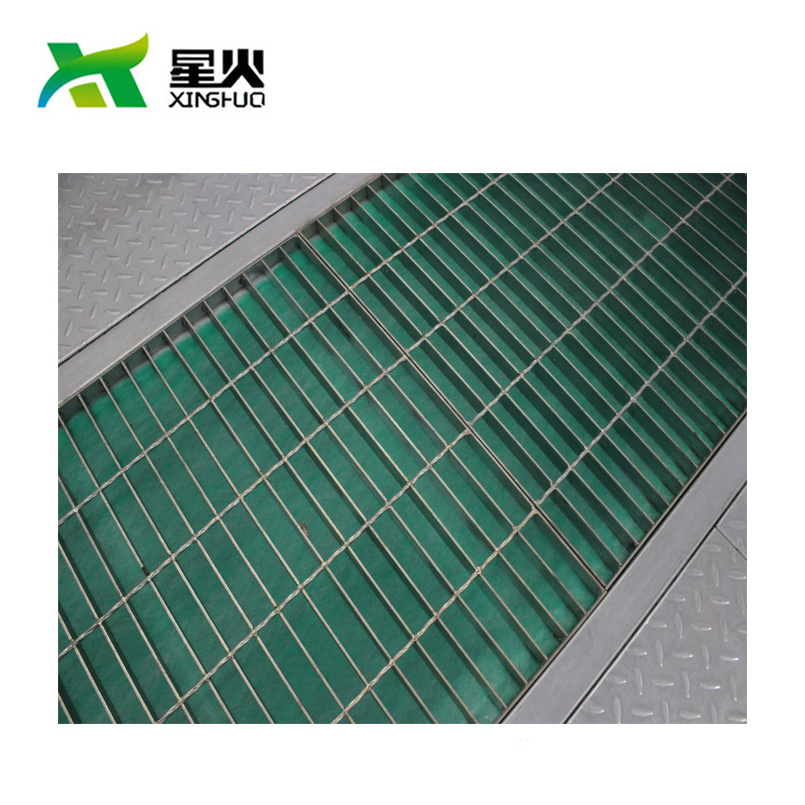

Air Filtration System

①The air inlet of the fan adopts the primary filter of the special air inlet cotton;

②The top of the static pressure chamber adopts CC-800XU advanced filter cotton for high-efficiency filtration;

③The bottom of the steel grille is equipped with bottom cotton paint mist filter felt for efficient filtration;

⑤The exhaust box body adopts 2 layers of paint mist filter cotton.

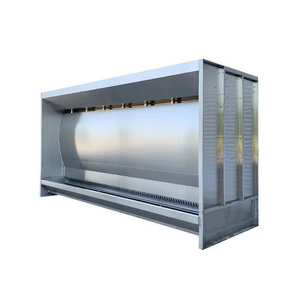

Fan system

①The air supply unit uses Jiangsu YDW double-inlet fans. According to the calculation of air volume, a total of 2 sets of 4kw fans are configured for air intake. The air supply volume of each fan is 12500m³/h, and the total air supply volume is 25000m³/h. , a total of 8kw.

Fan system

②The exhaust fan group adopts Jiangsu DKF type double air intake fan. The fan motor is external, and the external motor is covered by a special protective cover, which is convenient for maintenance; a total of 7.5KW fans are equipped to exhaust air, and the exhaust air volume of each fan is 20000m³ /h, a total of 7.5KW.

Heating system

Diesel heating: Italian G20 diesel burner, heat exchanger made of SUS304 high-quality stainless steel.

Heating system

A total of 10 sets of side-by-side heating and baking lamps are configured, each set of 3kw, a total of 30kw.

Heating system

Natural gas heating: Italian FS20 natural gas burner, heat exchanger made of SUS304 high-quality stainless steel.

Base system

③The steel grating is made of 30*5mm flat iron and 8# thread welding, with high strength;

④The checkered plate is folded from δ2.3mm steel plate. The bottom is welded with reinforcing ribs and the checkered plate to enhance the bearing capacity, and is treated with rust removal and plastic spraying, and the appearance is beautiful.

Base system

①The front and lower skirts of the house are made of δ1.2mm galvanized sheet, bent and welded, and reinforced; the other skirts are made of δ0.8mm galvanized sheet, bent and welded, and reinforced;

②The connecting legs are made of δ1.8mm galvanized sheet bent and welded into a "convex" structure, which has high strength and is used to support steel grilles and checkered plates;

Water-based paint system

①The water-based paint fan adopts YDW type double-inlet fan, with a total of 2 sets, each water-based paint fan is 0.55KW, and the total is 1.1KW;

②The special water-based paint air duct is made of δ1.0mm bending; the air supply duct is fixed with 2 sets of flexible connections and the top light box;

③The top lighting light box is equipped with 32 sets of water-based paint blowing nozzles, which can be rotated to adjust the wind direction;

④The water-based paint bellows is welded by 20*20mm galvanized square tube, with delta 0.8mm galvanized sheet skin, and contains 1 air supply purifying cotton, which is sprayed as a whole.

Hot Searches