- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

100-240V

-

Weight (KG):

-

200

-

Brand:

-

HICOLO

-

Name:

-

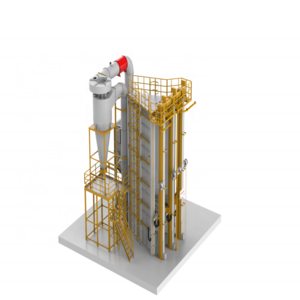

Fluidized bed powder coating dipping tank machine

-

MOQ:

-

1 PCS

-

Usage:

-

Powder Coating Workpieces

-

After Warranty Service:

-

Spare parts

-

Guarantee:

-

1 year

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

Fluidized bed, Fluidized bed

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

COLO

-

Voltage:

-

100-240V

-

Weight (KG):

-

200

-

Brand:

-

HICOLO

-

Name:

-

Fluidized bed powder coating dipping tank machine

-

MOQ:

-

1 PCS

-

Usage:

-

Powder Coating Workpieces

-

After Warranty Service:

-

Spare parts

-

Guarantee:

-

1 year

-

Certification:

-

CE

Product Description

Electrostatic fluidized bath for powder coating

Fluidized bath( fluidzed bed ) powder coating is a coating process where finely ground powder particles are suspended in air, and a preheated part is dipped into the powder bath. The melted particles fuse to the object, providing a consistent, even finish on metal parts.

Fluidizing the powder mimics the action of liquid dip coatings and eliminates the faraday cale effect of electrostatic spray,

allowing the powder to build on all surfaces, including inside corners, and welded wire products.

allowing the powder to build on all surfaces, including inside corners, and welded wire products.

Details Images

Fluidized bed powder coating equipment features

1.

Fluidized bed powder coating is

basically a low-tech coating method, and once coating parameters are established, there are not that many things that can go wrong.

2. Fluid bed coating will generally smooth over any small details in the parts, such as embossed serial numbers, metal

imperfections, etc.

3. Productivity increases, the ability to coat an entire rack of parts by a single dip into the coating tank can be very

efficient.

imperfections, etc.

3. Productivity increases, the ability to coat an entire rack of parts by a single dip into the coating tank can be very

efficient.

4. Fluidized bed coating is a fairly inexpensive system,

SS304 tank offers excellent durability, resistance to wear and rust,

and ongoing maintenance is most always lower.

5.

The fact that virtually 100% transfer efficiency is obtained, and the temperature in the bed is easy to maintain uniformity, powder either melts to the part or remains in the fluidized bed, and the configuration of the filter element recovery.

Fluidized Bed Appearance

Circulating Fan and Filter

Inside Fluidized Bed

Electrical Control Box

|

Centrifugal fan:

|

4kw, wind pressure of 1500Pa;

|

|

Wind pressure:

|

40-100kpa

|

|

Working size of fluidized bed:

|

W2200*H1500*D1400 mm

|

|

Base material

|

Stainless steel plate, thickness 2mm

|

|

The inner fluidized plate

|

2200*1400*20 mm (spliced by microporous plates)

|

|

Micropores

|

10-15 micron

|

|

Air inlet holes

|

6pcs, (4 points*12)

|

|

Quick-release filter

|

5pcs, (325*600mm)

|

Manufacturing Technique

Application

Fluidized bath powder coating applications

Fluidized Bed Powder Coatings are best suited for covering wire forms, irregular shaped products, sheet metal and metal stampings that require a thinner uniform protective coating.

Fluid Bed Coatings can provide coverage of many imperfections in the base materials, eliminating the need for secondary operations such as grinding and deburring. Depending on the application we can offer product preparation including sandblasting equipment and polishing machine to insure adhesion.

Recommend Products

Product packaging

Standard and Safety Export Packages

Inside with environment-friendly soft bubble paper , EPE foam wrapped well, carton outside for the delivery.

Inside with environment-friendly soft bubble paper , EPE foam wrapped well, carton outside for the delivery.

Hot Searches