- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

5 years

-

Technics:

-

Brushed

-

Place of Origin:

-

Gansu, China

-

Model Number:

-

PWC03

-

Brand Name:

-

YLSD

-

Material:

-

wood plastic composite, Wood plastic composite

-

Feature:

-

Waterproof, Fireproof, Anti-flaming, Wear-resistant, Anti-slip

-

Type:

-

Engineered flooring

-

Usage:

-

Indoor or outdoor

-

Surface Treatment:

-

3d embossing/CO-Extrusion Decking

-

Certificate:

-

CE, Certification

-

color:

-

customed

-

size:

-

customed

Quick Details

-

Project Solution Capability:

-

graphic design

-

Application:

-

Outdoor

-

Design Style:

-

Modern

-

Warranty:

-

5 years

-

Technics:

-

Brushed

-

Place of Origin:

-

Gansu, China

-

Model Number:

-

PWC03

-

Brand Name:

-

YLSD

-

Material:

-

wood plastic composite, Wood plastic composite

-

Feature:

-

Waterproof, Fireproof, Anti-flaming, Wear-resistant, Anti-slip

-

Type:

-

Engineered flooring

-

Usage:

-

Indoor or outdoor

-

Surface Treatment:

-

3d embossing/CO-Extrusion Decking

-

Certificate:

-

CE, Certification

-

color:

-

customed

-

size:

-

customed

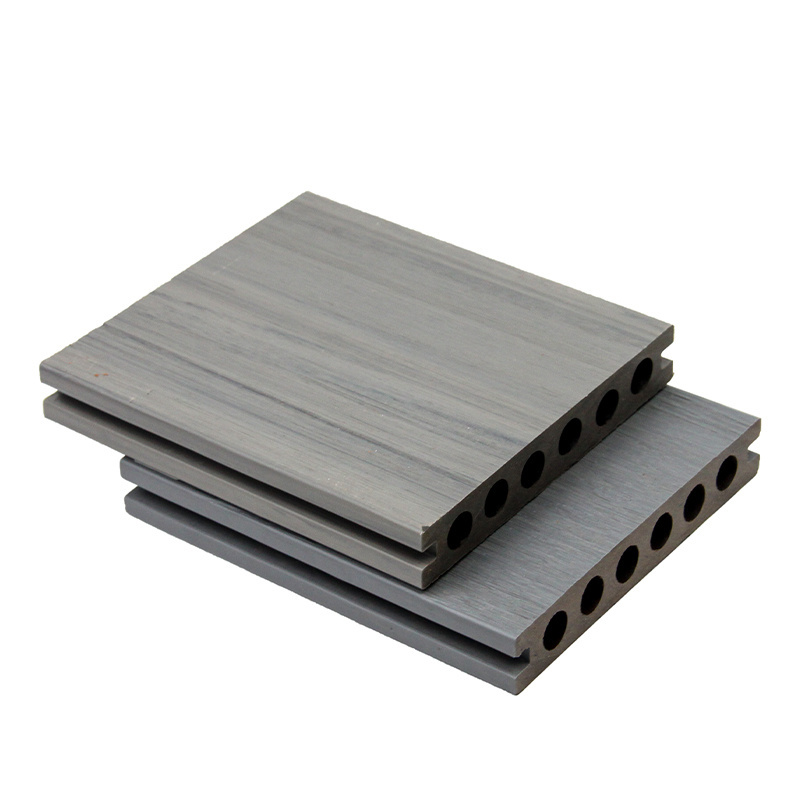

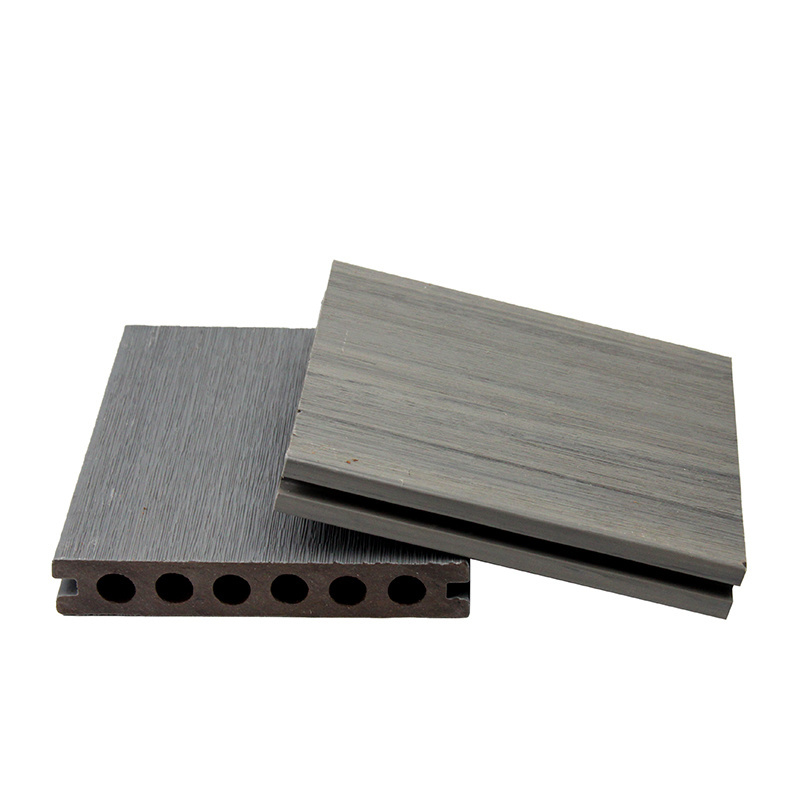

WPC composite outdoor decking terrace flooring solid hard wood flooring

Products Description

wpc decking ( wood-plastic composite) is the commonly used resin adhesive with polyethylene, polypropylene, PVC, mixed with more than 50% of the materials such as wood powder, rice shell, straw and other waste plant fibers to form new wood materials, and then plates or profiles are produced through plastic processing processes such as extrusion, molding and injection molding. Mainly used in building materials, furniture, logistics and packaging and other industries.

|

Product name

|

WPC decking floor

|

|

|

|

Working environment

|

-40~60 Degrees Celsius

|

|||||

|

Material

|

60% wood fiber+30% HDPE+10% additives

|

|

|

|

Slip Resistance Rate

|

Above 36

|

|||||

|

YBrand

|

YLSD

|

|

|

|

Water Absorption Rate

|

Less Than 2%

|

|||||

|

Size

|

140*24mm/140*25mm/145*24mm/150*25mm or customized

|

|

|

|

Fire Rating

|

Class B

|

|||||

|

Length

|

2.2 m/2.9m/3m/3.6m or customized

|

|

|

|

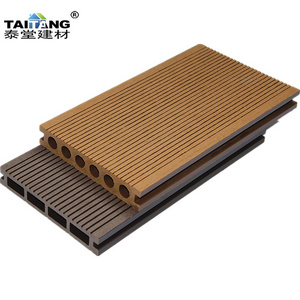

Colors

|

Black, Dark grey, Brown, Oak, Teak, White, Grey, Light grey or customized

|

|||||

|

Surface Treatment

|

Brushing, Sanding, Emobossing, Mixed Color, Wood Grain, Bamboo View,Groove, Sripe

|

|

|

|

Maintenance

|

Low Maintenance

|

|||||

|

Advantages

|

1. Eco-friendly, sustainable.2. Low maintenance. 3. Anti-slip, anti-insect, anti-termite, fire retartant, UV resistant, waterproof. 4. Easy installation.

|

|

|

|

|

|

|||||

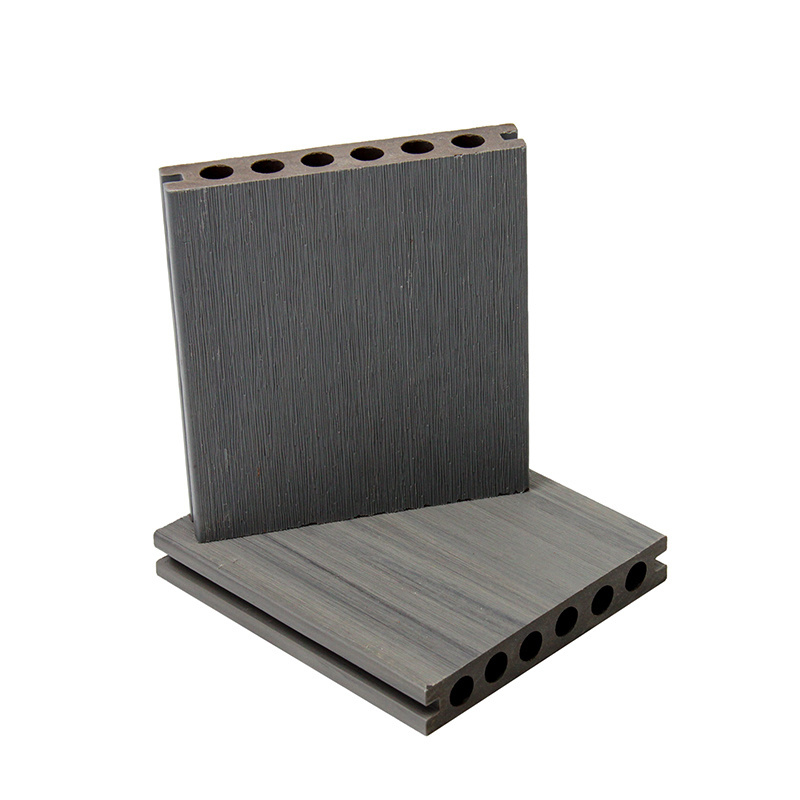

Co-extrusion technology of wpc floor

By adding a layer of functional material on the outer surface of the original product, the plastic-wood full-covering co-extrusion technology can improve the appearance strength, enhance the wear resistance, UV resistance and other functions, and make the product color and appearance more realistic. This kind of co-extrusion process developed on the basis of single-material extrusion not only improves the performance of products, but also expands application fields and product categories.

There are more and more fully covered co-extruded wood-plastic products on the market, not only the traditional high-end wood-plastic doors and windows, handrails, and fences use the wood-plastic co-extrusion process, but also more and more floors,fences, exterior wall panels, and templates. The plastic-wood full-covering co-extrusion process has become the mainstream trend of the industry.

Details Images

Best Services

★ Provide free samples for trial sale.

★ Try our best to meet and exceed customers' expectation --

Best prices, low MOQ, strictly quality control, on-time delivery and prompt responsiveness to customers' requirements.

★ Follow up and feed back tightly during production process.

★ Provide real pictures of loading container of bulk QC report before shipping.

★ Customized designs, colors, sizes and logos are welcome.

★ Price term and payment are negotiable.

Application Scenarios

WPC profile with two sides groove designing for slip resistance, can be used as floor board, be installed on theoutdoor ground, trestle road and garden path, and perform outstanding superiority in the outdoor decking of courtyard, park,garden community, waterscape, seashore path or gazebo, trestle and plank road, dock, etc

Installation Instructions

Tips:

1. Make sure the ground is flat or leveled before installation.

2. The composite wood planks can be easiy cut/ screwed/ sawed.

3. If the deck planks are to be paved suspended, it's highly suggested to build the support frame with galvanized steel or other steel made materials.

4. If the decking are to be installed around the swimming pool, it's better to leave slope on the ground, to allow better water

drainage.

5. When it comes to the corner, it's suggested to leave some space (2-5cm) between decking and wall.

3. If the deck planks are to be paved suspended, it's highly suggested to build the support frame with galvanized steel or other steel made materials.

4. If the decking are to be installed around the swimming pool, it's better to leave slope on the ground, to allow better water

drainage.

5. When it comes to the corner, it's suggested to leave some space (2-5cm) between decking and wall.

Hot Searches