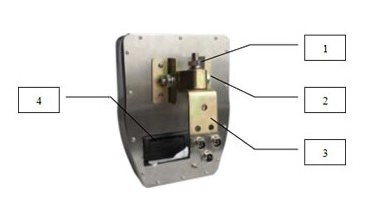

1: Fastening Nut for Lateral Rotation;

2: Fastening Nut for Vertical Rotation;

3:Locating Plate;

4: Printer

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Supmeter

-

Model Number:

-

BST106-N59[B]

-

Output Voltage:

-

DC12V

-

Max. Output Current:

-

100mA

-

COM1:

-

RS232

-

IP Grade:

-

IP65

Quick Details

-

Power Supply:

-

24V

-

Display Type:

-

TFT color display screen

-

Warranty:

-

1year

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Supmeter

-

Model Number:

-

BST106-N59[B]

-

Output Voltage:

-

DC12V

-

Max. Output Current:

-

100mA

-

COM1:

-

RS232

-

IP Grade:

-

IP65

Operating Principle

1.Wheel Loader Weigher is a dynamic weighing and auto-totalizing equipment installed on wheel loader.

2.When the lift-arm of wheel loader lifted to a certain height, the position sensor will trigger the weighing process, and the weighing indicator will collect the oil pressure signal from lower and upper oil chambers of arm-lifting oil cylinder. After signal processing and compensating, Single-bucket-loading -weight will be got and totalized to Totalized Loading Weight automatically The operator can judge if the present Single-bucket-loading-weight is valid according to the alarm messages, and confirm the last bucket's loading weight according to the negative deviation value.

Main Features

1.EMC design with high anti-jam for industrial environment.

2.DC24V power input with reverse polarity protection.

3.32-bit ARM CPU with 72MHz & higher arithmetic speed.

4.Dust-proof stainless steel shell with protection level IP65.

5.640×480 TFT display screen with English display and input.

6.24-bit ∑-△ADC with internal resolution 1/1,000,000.

7.High sampling frequency 400Hz.

8.Special Anti-vibration Digital Filtering Algorithm for precise weighing, stable display and rapid response.

9.Special Acceleration Compensation Algorithm.

10.10000 Loading Records can be saved.

11.Each record can contain 50 Single-bucket-loading-weight.

System Accuracy

1.Accuracy Grade: III.

2.Verification Accuracy of Weighing Indicator: 0.02%.

3.Accuracy of Single-Bucket-Weight: 0.5%~1.0%.

4.Accuracy of Totalized Loading Weight: 1.0%.

System Configuration

1 Position sensor.

2 Oil pressure sensors.

2 Plate type three-way joints.

1 Mounting fitting.

Installation of Weighing Indicator

Installation of Weighing Indicator

Installation of Position Sensor

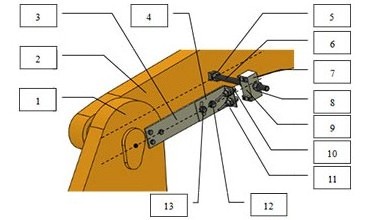

Position sensor includes two modules:

1.Proximity Switch Module: Main Mounting Plate with a chute for length adjustment, Sub-mounting Plate with a chute for angle adjustment, Upper Proximity Switch and Lower Proximity Switch [Detecting Distance: 1~8mm].

2.Magnet Module: Thread Pole, Weld-nut, Tight-nut, Nylon Block, Magnet Block.

1: Lift-arm Seat; 2: Lift-arm; 3: Main Mounting Plate; 4: Sub-mounting Plate; 5: Weld-nut; 6: Thread Pole; 7: Nylon Block; 8: Fastening Nut for Position Ajustment; 9: Magnet Block; 10: Upper Proximity Switch; 11: Upper Proximity Switch; 12: Fastening Nut for Length Ajustment; 13: Fastening Nut for Angle Ajustment.

|

Menu Operation

|

|

|

|

Key Name

|

Description

|

|

|

[Menu]

|

Enter Main Menu / Exit.

|

|

|

[Ent]

|

Enter / Save.

|

|

|

[◄]

|

Cursor shifts left. Backspace.

|

|

|

[►]

|

Cursor shifts right.

|

|

|

[▲]

|

Cursor shifts up. Display the previous option.

|

|

|

[▼]

|

Cursor shifts down. Display the next option.

|

|

|

Parameter Setting Operation

|

|

System Calibration Operation

|

|

||

|

Key Name

|

Description

|

Key Name

|

Description

|

||

|

[Set]

|

Setpoint Parameters Setting.

|

4/[Zero]

|

Zero Calibration with unloading and idle speed.

|

||

|

[0~9]

|

Number Input.

|

7/[Z.cmp]

|

Zero Compensation with unloading and accelerating.

|

||

|

[A-Z]

|

English Alphabet Input.

|

5/[Cal]

|

Span Calibration with loading and idle speed.

|

||

|

[Print]/[IME]

|

Input Method Switch: Number / English / Chinese PinYin.

|

8/[S.cmp]

|

Span Compensation with loading and accelerating

|

||

|

Operation in Loading Process

|

|

|

|

|||

|

Key Name

|

Description

|

Key Name

|

Description

|

|||

|

6/[Mode]

|

Options: Truck Mode / Mix Mode.

|

[Print]

|

Print Loading Records.

|

|||

|

[Load]

|

Enter Loading state with blue sign '▲' displaying.

Let the bucket of wheel loader stay at the lowest position before pressing[Load] |

1/[Disp]

|

|

|||

|

|

Truck Mode: Save the current Loading Record and Clear Screen after the truck-loading process finished.

|

2/[Lock]

|

Key-locking.

Key-unlocking. |

|||

|

|

Mix Mode: Save the Loading Record of the current Material No. and Clear Screen.

|

3/[Deduct]

|

Deduct the next Single-bucket-loading-weight from Totalized Loading Weight.

|

|||

|

[No.]

|

Truck Mode: it's for inputting Truck No..

|

9/[Rec]

|

F3 Record Management [Query/Clear/USB Copy].

|

|||

|

|

Mix Mode: it's for changing Material No..

After the new Material No. inputted, the current Material No.'s Loading Record will be saved automatically, and then the new Material No.'s historical Loading Record will be displayed again for material-reloading operation. |

0/[Cls]

|

|

|||

|

[Pause]

|

Enter Pause state with red sign '■' displaying

|

[On/Off]

|

Press it to turn the power on.

Keep it pressed for 2 seconds to turn the power off. |

|||

|

[Void]

|

Cancel Totalizing: After totalizing, the present Single-bucket-loading-weight can be deducted from Totalized Loading Weight via this key.

Cancel Deducting: After deducting, the present Single-bucket-loading-weight can be totalized to Totalized Loading Weight again via this key. |

[Ent]

|

Backlight Switch of Keypad.

Auto-on time of keypad backlight: 17:00~8:00; Auto-off time of keypad backlight: 8:00~17:00.

Check if the U-disk is ready.

|

|||

Handling:

Multiple purchases saving plan: Please make sure single payment for each item you won. We will combine the shipping when you make multiple purchases.