High strength

Heat resistant

High resistant to abrasion

Low elongation

Resistant to impact

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

EP150/EP200, EP300/3EP800/4

-

Product name:

-

PATTERN Conveyor Belt

-

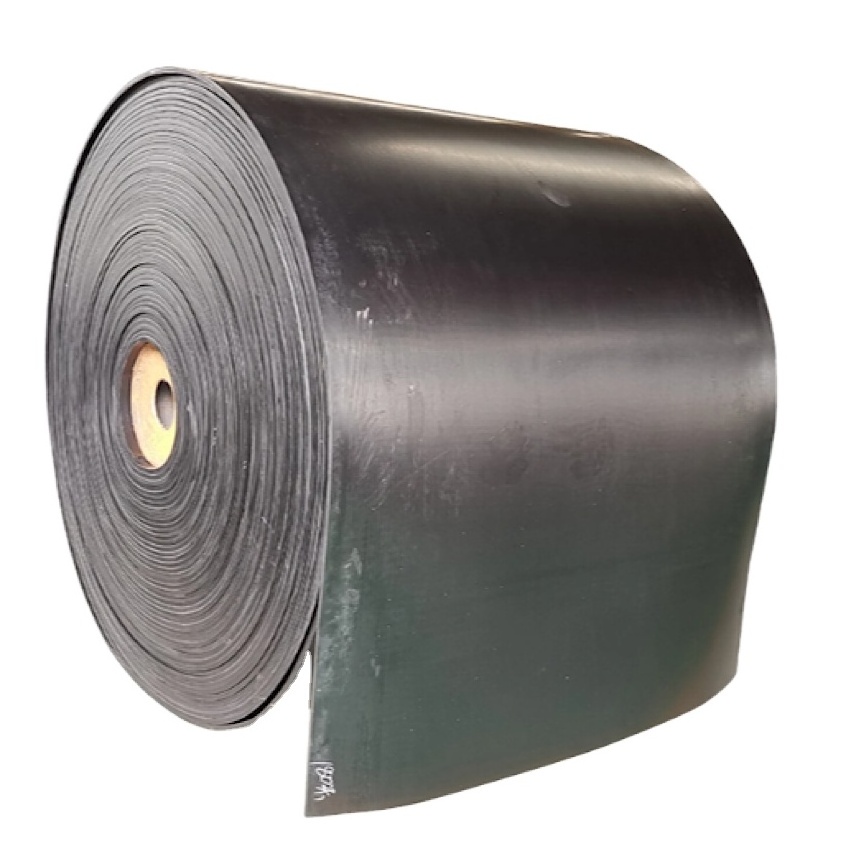

Materials:

-

Rubber+EP Fabric

-

MOQ:

-

1 METER

-

Elongation at Break:

-

350%-450%

-

Certification:

-

IS09007.1S014007

-

Edge:

-

Mould Edqe/Cut Edge

-

Standards:

-

GB/TG770-2001/DIN221 02/JISK6

-

Rubber Grade:

-

8Mpa-25Mpa

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KILOMEGA, Kilomega

-

Model Number:

-

EP150/EP200, EP300/3EP800/4

-

Product name:

-

PATTERN Conveyor Belt

-

Materials:

-

Rubber+EP Fabric

-

MOQ:

-

1 METER

-

Elongation at Break:

-

350%-450%

-

Certification:

-

IS09007.1S014007

-

Edge:

-

Mould Edqe/Cut Edge

-

Standards:

-

GB/TG770-2001/DIN221 02/JISK6

-

Rubber Grade:

-

8Mpa-25Mpa

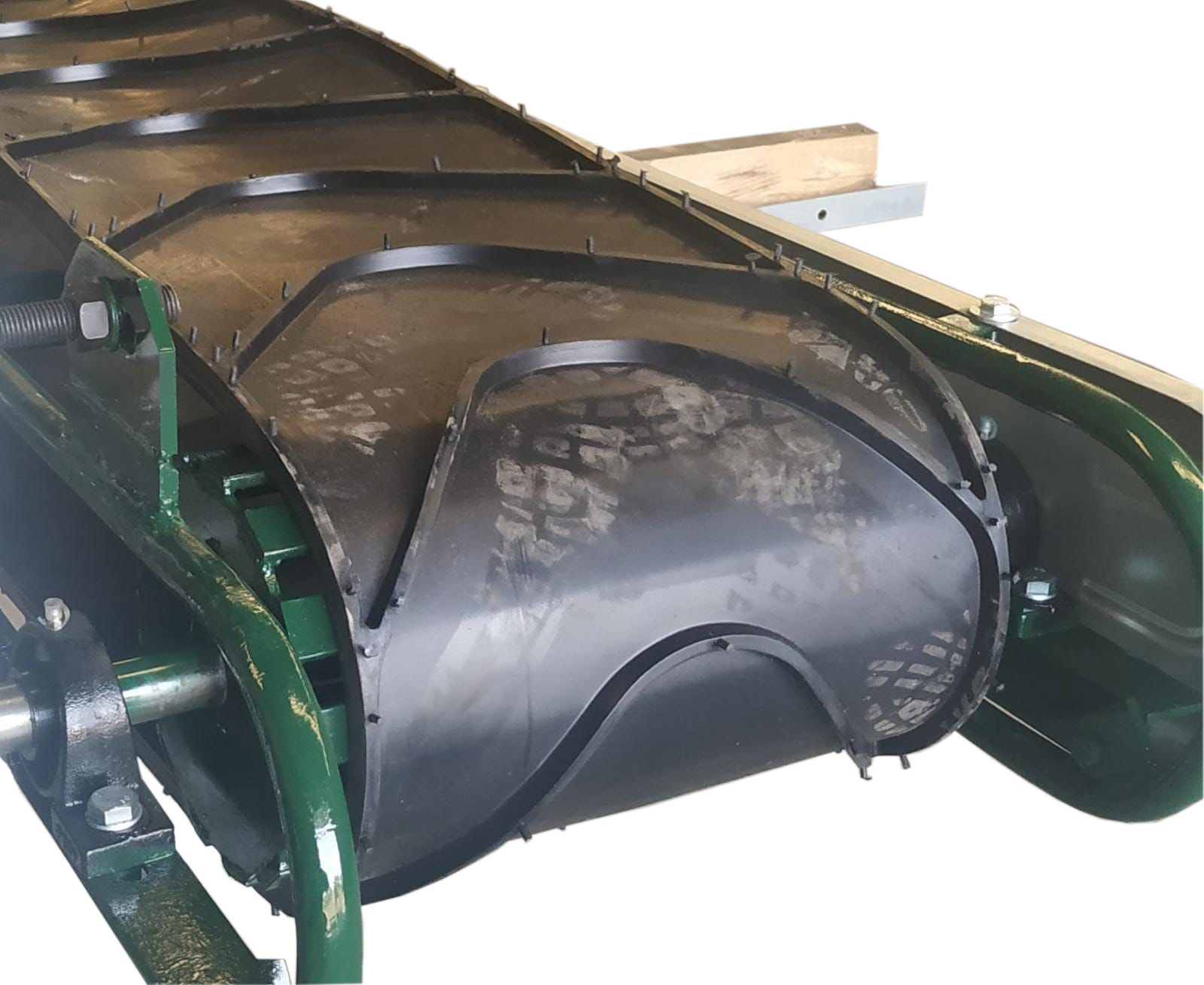

Products Description

For steep angle conveying with incline less than 45° Allows the use of smaller pulley diameters.

Cleat height range from 5mm to 25mm which is suitable to conveyor bulk material up to 80mm lump size.

Cleat height range from 5mm to 25mm which is suitable to conveyor bulk material up to 80mm lump size.

Title goes here.

from400up to 1200 mm

Specification

|

Type

|

Belt width

|

Cleat width

|

Cleat pitch

|

Cleat angle

|

Cleat angle

|

|

C5

|

500-1200

|

full-width

|

100

|

5

|

120 Degree

|

|

C10

|

500-1200

|

full-width

|

150

|

10

|

120 Degree

|

|

C15

|

500-1200

|

full-width

|

200

|

15

|

120 Degree

|

|

C15V330

|

400

|

330

|

250

|

15

|

60 Degree

|

|

|

450

|

330

|

250

|

15

|

60 Degree

|

|

|

500

|

330

|

250

|

15

|

60 Degree

|

|

|

600

|

330

|

250

|

15

|

60 Degree

|

|

|

650

|

330

|

250

|

15

|

60 Degree

|

|

C15V450

|

600

|

450

|

250

|

15

|

60 Degree

|

|

|

650

|

450

|

250

|

15

|

60 Degree

|

|

|

700

|

450

|

250

|

15

|

60 Degree

|

|

C15P385

|

450

|

385

|

250

|

15

|

60 Degree

|

|

|

500

|

385

|

250

|

15

|

60 Degree

|

|

|

550

|

385

|

250

|

15

|

60 Degree

|

|

|

600

|

385

|

250

|

15

|

60 Degree

|

|

|

650

|

385

|

250

|

15

|

60 Degree

|

|

C15P600

|

750

|

600

|

250

|

15

|

60 Degree

|

|

|

800

|

600

|

250

|

15

|

60 Degree

|

|

|

900

|

600

|

250

|

15

|

60 Degree

|

Quality Control

Step 1: Advance equipment to guarantee quality from the details

Precise calender process

4 rollers celender machine is able to stick rubber on both side of the fabric in one time.This can reduce the strength loss of the rubber during the process.

Forming process

The forming tension is even between different plies,which can avoid wrinkled fabric and guarantee an even thickness of belt core.

Step 2:Finished belts inspection

We have an inspection team to inspect the surface and dimension of each conveyor belt.

Length and surface inspection

Thickness inspection

WIdth inspection

Step 3: Technical data test

We have a lab to test all raw materials and rubber compound.For each roll of conveyor belt,the lab will test the following features, and issue Quality Test Report.

Abrasion test

Adhesion strength test

Tensile strength test

2023 The China Import and Export Fair

Packing&Application

Hot Searches