- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DAC-HPMg

-

Shape:

-

Magnesium anode in D type, R type, S type,etc.

-

Material:

-

magnesium alloy anode

-

Dimensions:

-

Customer's Demands

-

Chemical Composition:

-

Magnesium anode-Mg,Al,Zn,Mn,Fe,Cu, Mg balance

-

Product name:

-

Cathodic Protection High potential Magnesium Alloy Sacrificial Anode

-

Product technology:

-

Casting Magnesium Anode Sacrificial anode cathodic protection

-

Magnesium anode Model Number:

-

MIC,High potential,AZ63B Casting Magnesium Anode Sacrificial anode

-

Standard:

-

ASTMB843-M1C, ASTMB843-AZ63B Casting Magnesium Anode Sacrificial anode

-

Color:

-

silver

-

Usage:

-

Buried pipelines, steel structure in water, boat, storage tanks, etc.

-

Density:

-

1.8G/CM3

Quick Details

-

Application:

-

Magnesium anode use for cathodic protection

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Durable

-

Model Number:

-

DAC-HPMg

-

Shape:

-

Magnesium anode in D type, R type, S type,etc.

-

Material:

-

magnesium alloy anode

-

Dimensions:

-

Customer's Demands

-

Chemical Composition:

-

Magnesium anode-Mg,Al,Zn,Mn,Fe,Cu, Mg balance

-

Product name:

-

Cathodic Protection High potential Magnesium Alloy Sacrificial Anode

-

Product technology:

-

Casting Magnesium Anode Sacrificial anode cathodic protection

-

Magnesium anode Model Number:

-

MIC,High potential,AZ63B Casting Magnesium Anode Sacrificial anode

-

Standard:

-

ASTMB843-M1C, ASTMB843-AZ63B Casting Magnesium Anode Sacrificial anode

-

Color:

-

silver

-

Usage:

-

Buried pipelines, steel structure in water, boat, storage tanks, etc.

-

Density:

-

1.8G/CM3

Cathodic Protection High potential Magnesium Alloy Sacrificial Anode for underground pipelines

Cathodic Protection High potential Magnesium Alloy Sacrificial Anode for underground pipelines

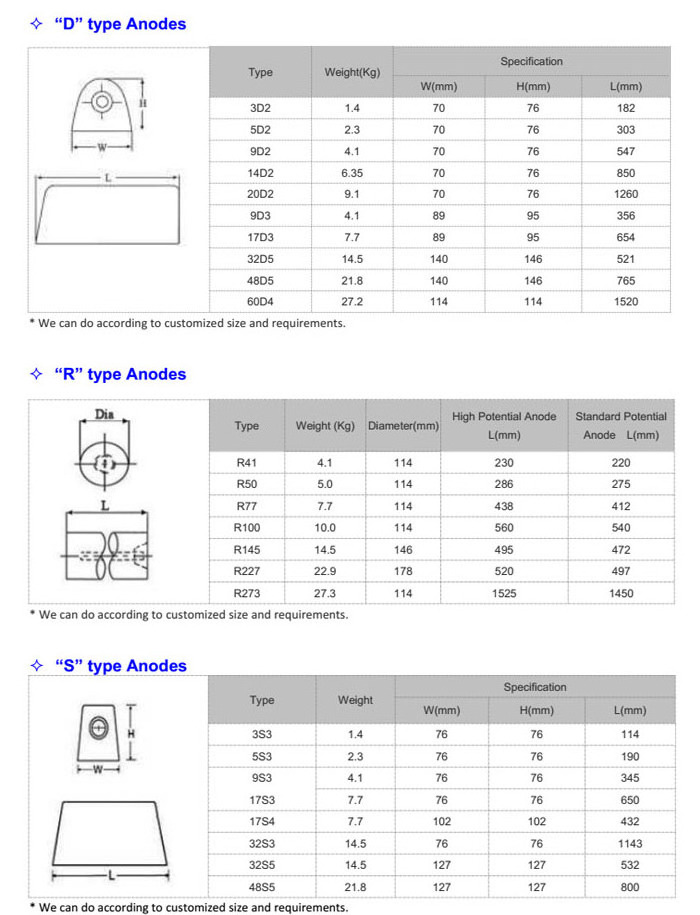

♦ Specifications

High Potential Magnesium anode is used as a sacrificial anode in cathodic protection. Magnesium has the highest driving voltage of all the materials used for sacrificial anodes. if it is placed within a system that uses large amounts water, it attracts the corrosion away from other components.

Our magnesium anode all manufactured and tested according to latest international standards, such as ASTM B843 and ASTM G97,It ’ s available from both M1C( high Potential)or AZ63B(standard Potential)magnesium anode.

♦ Application :

High Potential Magnesium anode fight corrosion effectively and economically, and are commonly used in marine environments , soil environment,etc.. They protect a variety of steel structures in salt, brackish and fresh water, including: Buried Oil gas Pipelines, Storage tanks, Boats, Ballast tanks, Bulkheads, Pilings, Heat exchangers, etc.

² Boats ² Ballast tanks ² Bulkheads ² Water storage tanks

² Pilings ² Pipelines ² Heat exchangers

Magnesium anodes corrode much more easily than the materials they are protecting, drawing the corrosion away from equipment.

♦ Chemical compositions of High Potential Magnesium Anode :

|

Type |

Al (Max) |

Mn |

Cu (Max) |

Ni (Max) |

Si (Max) |

Fe (Max) |

Single impurity (Max) |

Total Impurity (Max) |

Mg |

|

M1C |

0.01 |

0. 5-1.3 |

0.005 |

0.001 |

0. 05 |

0.01 |

0.05 |

0.3 |

Remaining |

♦ Electrochemical properties of High Potential Magnesium Anode:

|

Type |

Open-circuit voltage (-V) |

Close-circuit voltage (-V) Zn |

Actual capacitance (A·h/ k g) |

Current efficiency (%) |

|

M1C |

1.70-1.75 |

1. 58 -1. 62 |

≥1 100 |

≥50 |

* We can do according to customized size and requirements .

♦ Structure & Dimension

* The above specification only are small part of our products list, we have much more specification size, and also special shape, size and chemical composition anodes can be manufactured according request, please contact us for more information.