- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

customized

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Boiler Economizer

-

Model Number:

-

Bare type Economizer

-

Price:

-

Negotiable

-

Surface Treatment:

-

Painted

-

Application:

-

Power Station, Industrial

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HDB Boiler Economizer, HD Boiler

-

Dimension(L*W*H):

-

customized

-

Weight:

-

customized

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Boiler Economizer

-

Model Number:

-

Bare type Economizer

-

Price:

-

Negotiable

-

Surface Treatment:

-

Painted

-

Application:

-

Power Station, Industrial

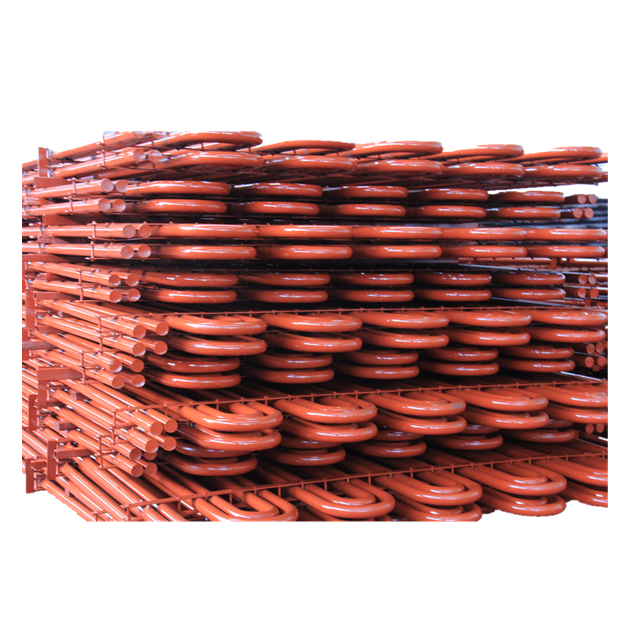

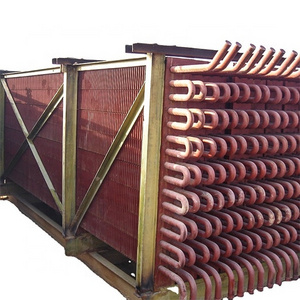

Boiler Economizer

Energy Saving Exhaust Gas Boiler Economizer Equipment for 200MW Coal Fired Steam Boiler

Introduction

Economiser performs a key function in providing high overall boiler thermal efficiency by recovering the low level energy from the flue gas before it is exhausted to the atmosphere. Economiser recovers the energy by heating the boiler feedwater.Economiser are basically tubular heat transfer surfaces used to preheat boiler feed water before it enters the steam drum or furnace surfaces. Economiser reduces operating costs or economise on fuel by recovering extra energy from the flue gas.

Procedure

Economisers also reduce the potential of thermal shock and strong water temperature fluctuations as the feed water enters the drum or waterwalls. Increasingly stringent environmental regulations limiting nitrogen oxides and sulfur dioxide emission can also affect economizer design. The gas-side heat transfer coefficient is much less than water side heat transfer coefficient. To compensate this, outer surface of the tubes may be finned to increase the surface area of heat transfer. The ultimate goal of economizer design is to achieve the necessary heat transfer at minimum cost. A key design criterion for economizer is maximum allowable flue gas velocity. Higher velocity provide better heat transfer and reduce capital cost.

Specifications

|

Name(unit) |

Specification(mm) |

|

Bare pipe(OD) |

25-1650 |

|

Bare pipe(Thickness) |

2-40 |

|

Fin (Thickness) |

0.6-3.0 |

|

Fin (Height) |

5-30 |

|

Fin tube thread pitch |

5-30 |

|

Fin tube length |

≤12000 |

Material:Carbon Steel,Alloy,Austenitic Steel(Nickel and Chromium or Manganese)

Quality Control

1. Impact test and Strength calculation report with applied materials information.

2. 100%NDT(non-destructive inspection) report of steel plate, tube and electrode.

3. X-ray, γ-ray and liquid penetrant test inspection report (welding seam): to ensure the quality of the entire boiler.

4. Hydraulic test report: ensure the standard working pressure and safety.