- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ruika

-

Wheels Standards::

-

AAR, UIC, EN, GOST, IRIS, KSR, BS, JIS,TB

-

Certifications::

-

IISO9001, ISO14001, OHSAS18001,TSI, AAR

-

Application::

-

road-rail vehicles, trppley, cranes

-

Wheel Diameter::

-

100mm to 1250mm

-

Supply Ability::

-

5000 Piece/Pieces per Month

-

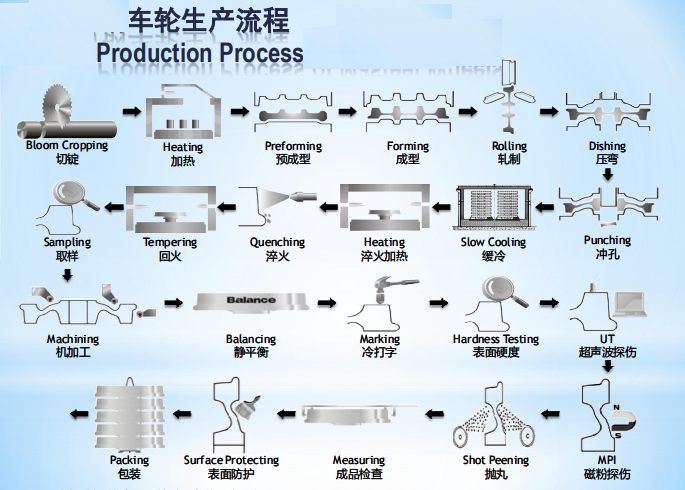

Process::

-

Forging-machining-heat treatment-machining-inspection-package

Quick Details

-

Material:

-

As Customer's Drawings

-

Dimensions (L x W x H) (mm):

-

As Customer's Drawings

-

Place of Origin:

-

China

-

Brand Name:

-

Ruika

-

Wheels Standards::

-

AAR, UIC, EN, GOST, IRIS, KSR, BS, JIS,TB

-

Certifications::

-

IISO9001, ISO14001, OHSAS18001,TSI, AAR

-

Application::

-

road-rail vehicles, trppley, cranes

-

Wheel Diameter::

-

100mm to 1250mm

-

Supply Ability::

-

5000 Piece/Pieces per Month

-

Process::

-

Forging-machining-heat treatment-machining-inspection-package

Product Description

Widely used in logistics, freight wagon, muck car, and other railway transport. It can be designed and manufactured according to user’s requirement, and it also can be manufactured and processed at any time according to customers’ samples and drawings.

| Item | Railway wheel/ Railway Rolling Stock Bogie Wheels |

| Materials | UST provide forged wheels and cast wheels to many international standards |

| Standards | Wheels confirm to every recognized international quality standard: AAR M-107, UIC 811-1, EN13261, GOST 31334, IRIS 16/95, KSR 9220, BS 5892, JIS E4502, TB/T 2945 |

| Type | Freight Wagon Wheels, Passenger Coach Wheels, Locomotive Wheels and many other industrial or mine vehicles wheels |

| Test | 100% inspection before delivery Chemical analysis, Metallographic, Mechnical analysis, Ultrasonic testing, Magnetic testing, Impact testing, Hardness testing, Surface quality and dimension report |

| Certifications | ISO9001,ISO14001, OHSAS18001, AAR, IRIS, TSI |

| Production capacity | 1 million pcs/year |

| Processing | rooled/forging-castingCNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc. |

| Market | United States, Canada, Brazil, Australia, India,South Africa, Russia, Iran, Pakistain, Iraq, Egypt, Germany, Chile, Uzbekistan and others country |

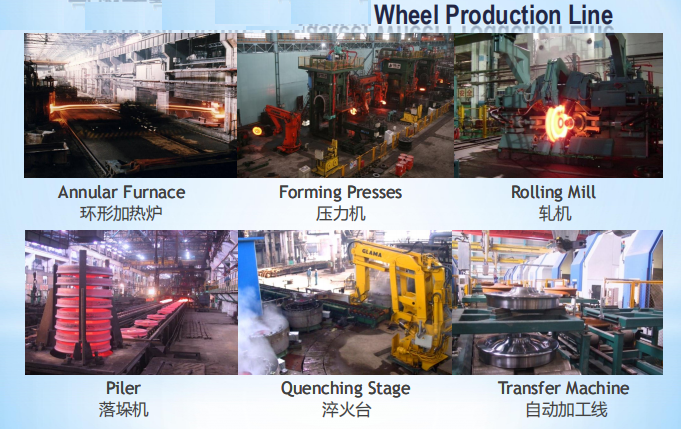

Production process

100% inspection before delivery, guarantee all products are qualified

Packaging & Shipping

Four or five pcs in one bunch, packaged in Nylon Bag or Wooden cases: export wooden cases with fumigation certifications.

Certifications

Certifications

Hot Searches