- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Patron 2000C (4000W and below) Patron 2000S (6000W)Z

-

Cutting Thickness:

-

1-20mm

-

Place of Origin:

-

Shandong, China

-

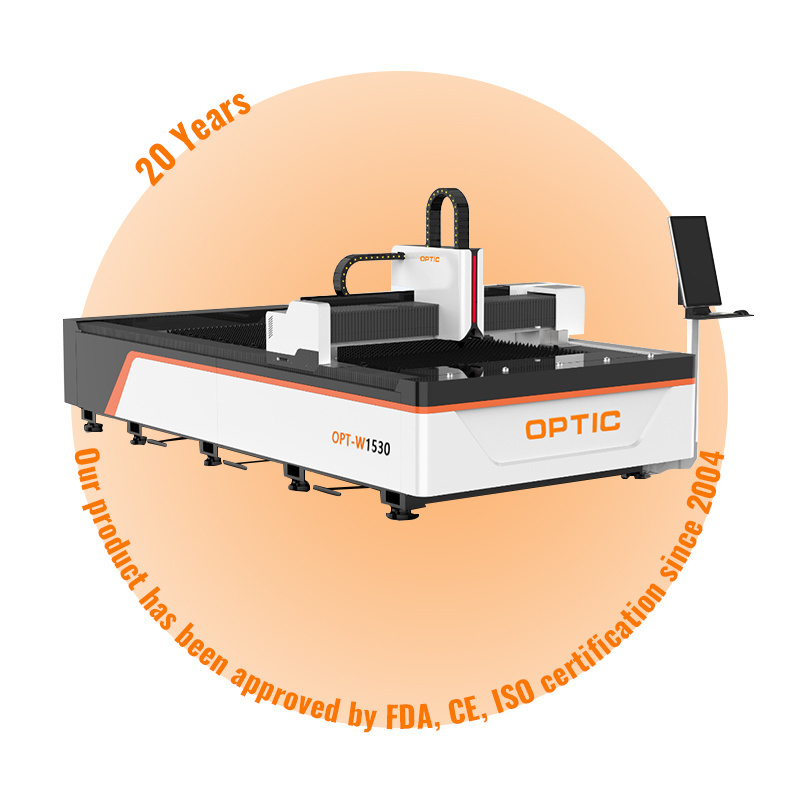

Brand Name:

-

OPTIC-XT

-

Weight (KG):

-

4600 KG, 4600kg

-

Control Software:

-

OPTIC-XT

-

Max.Acceleration:

-

1.5G

-

Working area:

-

1530mm*3050mm

-

Power supply:

-

1000W / 2000W / 3000W/4000W / 5000W/6000W

-

Platform fastest exchange time:

-

25s

-

Product name:

-

Fiber Laser Cutter

-

Maximum linkage speed:

-

120m/min

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

120m/min, 120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Patron 2000C (4000W and below) Patron 2000S (6000W)Z

-

Cutting Thickness:

-

1-20mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OPTIC-XT

-

Weight (KG):

-

4600 KG, 4600kg

-

Control Software:

-

OPTIC-XT

-

Max.Acceleration:

-

1.5G

-

Working area:

-

1530mm*3050mm

-

Power supply:

-

1000W / 2000W / 3000W/4000W / 5000W/6000W

-

Platform fastest exchange time:

-

25s

-

Product name:

-

Fiber Laser Cutter

-

Maximum linkage speed:

-

120m/min

Product Description

Application Materials

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Fiber Laser Cutting Machine Advantages

1. High quality laser beam: The focusing spot is smaller, with a diameter between 0.1 and 0.3 millimeters,

2. More precise cutting lines, higher work efficiency, and better processing quality

3. High energy density: million watts per square centimeter

4. Fast cutting speed: twice the same power CO2 laser cutting machine

5. Strong stability: Stable performance, with a service life of up to 100000 hours for key components

6. High electro-optical conversion efficiency: The photoelectric conversion efficiency of the fiber laser cutting machine is about 25%, which is three times that of the CO2 laser

cutting machine. It is energy-saving and environmentally friendly.

7. Low usage cost: The power consumption of the entire machine is only 20-30% of that of CO2 laser cutting machines

8. Low maintenance cost: no laser working gas; Fiber optic transmission without the need for reflective lenses; Can save a lot of maintenance costs

9. Easy to operate: Fiber optic transmission, no need to adjust the optical path

10. Strong flexible light guiding effect: compact in size, compact in structure, easy to meet flexible processing requirements

Main Components

1. Working table

2. Motors (XYZ axis): high efficiency, strong power

3. Transmission structure: high accuracy, high efficiency

4. Computer control system

5. Laser source, smallest laser spot to 0.1mm, meeting requirements for super accurate cases

6. Laser cutting gun/head

7. Optional: red light, makes lsaer visible

8. Optional: idler wheel, clamp

Specification

|

OPT-H1530

|

|

|

||

|

SYSTEM CONFIGURATION

|

ITEM

|

PARAMETERS

|

||

|

Overall Information

|

Cutting Area

|

1530x3050

|

||

|

|

Bearing Weight by Thickness

|

800kg

|

||

|

|

Machine Dimension

|

4920*2280*2000mm

|

||

|

|

Machine Weight

|

2200kg

|

||

|

|

Maximum Driving Speed

|

100m/min

|

||

|

|

Maximum Accelerating Speed

|

0.8g

|

||

|

|

Positioning Accuracy

|

±0.03mm/m

|

||

|

|

Re-Positioning Accuracy

|

0.02mm

|

||

|

Machine Power Input

|

Total Power/Current with a 6KW Laser Source

|

Unavailable

|

||

|

|

Total Power/Current with a 4KW Laser Source

|

30KVA/50A

|

||

|

|

Total Power/Current with a 3KW Laser Source

|

25KVA/42A

|

||

|

|

Total Power/Current with a 2KW Laser Source

|

22KVA/35A

|

||

|

|

Total Power/Current with a 1.5KW Laser Source

|

18KVA/28A

|

||

|

|

Total Power/Current with a 1KW Laser Source

|

15KVA/25A

|

||

|

Cuuting Accuracy, 1mm Stainless Steel

|

φ30mm, Circular Degree

|

±0.1mm

|

||

|

|

30mm Difference Value of Adjacent Side

|

±0.05mm

|

||

|

|

190mm Difference Value of Adjacent Side

|

±0.05mm

|

||

|

|

190mm Difference Value of Diagonal Line

|

±0.1mm

|

||

|

Machinery Configuration

|

Cutting Bed Structure

|

Stainless Steel

|

||

|

|

Transom Structure

|

Enhanced Aluminum

|

||

|

|

Liner

|

PEK

|

||

|

|

Rack

|

T-win brand from Taiwan

|

||

|

|

Auto Lubricating

|

Yes

|

||

|

|

Rotary Console

|

Yes

|

||

|

Electric Configuration

|

Servo Motor&Driver

|

2. >1000W VEICHI Bus Servo Motor(X:1KW Y:1KW Z:0.4KW)

|

||

|

|

Reduction Box

|

TFO

|

||

|

|

Electric Proportional Valve

|

SMC Cutting Gas Circuit(≤3KW) Aventics Cutting Gas Circuit(≥4KW)

|

||

|

|

Oxygen Controlling Valve

|

|

||

|

|

N2 Controlling Valve

|

Optional

|

||

|

Optical Device

|

Laser Head

|

OPTIC&XT

|

||

|

|

|

≤1000W Manual Focusing

|

||

|

|

|

≥1500W Auto Focusing

|

||

|

Operating System

|

Control System

|

Powered by OPTIC&XT

|

||

|

|

Cutting Software

|

Powered by OPTIC&XT

|

||

|

|

Laser Cuuting Parameters Guiding

|

Yes,preinstalled

|

||

|

|

Format Supported

|

G file, DXF, PLT, ENG

|

||

|

Intelligent Auxiliary System

|

Color Monitor Size

|

21.5"

|

||

|

|

Monitor Function

|

User Interaction

|

||

|

|

Remoter

|

Yes

|

||

|

|

|

≤3000,oxygen

|

||

|

|

|

4000, oxygen/N2

|

||

|

|

Cutting Gas Pressure Auto Controlling

|

Yes, oxygen

|

||

|

|

|

N2, optional

|

||

|

Security Configuration

|

Abnormal Laser Source Warning

|

Yes

|

||

|

|

Abnormal Laser Cutting Warning

|

Yes

|

||

|

|

Abnormal Cooling System Warning

|

Yes

|

||

|

Auxiliary Device

|

Water Cooling System

|

Yes

|

||

|

|

Dust Removing System

|

Yes

|

||

|

Optional Device

|

Dust Collector, Default without Centrifugal Fan

|

|

||

|

|

WIFI

|

|

||

|

|

Secure Light Curtain

|

|

||

|

|

Air Compressor

|

|

||

|

|

Voltage Stabilizer

|

|

||

|

|

Air Conditioner in Electrical Control Cabinet

|

|

||

|

|

Protection Glasses

|

|

||

|

|

Relief Valve for Oxygen&N2

|

|

||

|

|

Protection Board on Material Loading Side

|

|

||

|

|

Base Anchor

|

|

||

|

|

Expansion Bolt

|

|

||

|

ITEM

|

VALUE

|

|

Application

|

LASER CUTTING

|

|

Applicable Material

|

Acrylic, Glass, Leather, MDF, metal, Paper, plastic, Plexiglax, Plywood, Rubber, Stone, wood, Crystal

|

|

Condition

|

New

|

|

Laser Type

|

Fiber Laser

|

|

Cutting Area

|

1500*3000mm/4000*2000mm/6000*2000mm

|

|

Cutting Speed

|

120mm/min

|

|

Graphic Format Supported

|

AI, PLT, DXF, BMP, LAS, DXP

|

|

Cutting Thickness

|

0-30mm

|

|

CNC or Not

|

YES

|

|

Cooling Mode

|

WATER COOLING

|

|

Place of Origin

|

China

|

|

Province

|

Guangdong

|

|

Brand Name

|

OPTIC

|

|

Certification

|

ce, ISO

|

|

Laser Source Brand

|

RAYCUS/IPG

|

|

Weight (KG)

|

2900KG

|

|

Key Selling Points

|

Easy to Operate

|

|

Warranty

|

2 years

|

|

Aftersale

|

Online support, Video technical support

|

|

After Warranty Service

|

Video technical support, Online support

|

|

Applicable Industries

|

Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works , Other

|

|

Local Service Location

|

None

|

|

Showroom Location

|

None

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Marketing Type

|

New Product 2023

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

laser source

|

|

Laser power

|

500W / 1000W / 2000W / 3000W/4000W

|

|

Product name

|

Fiber Laser Metal Cutting Machine

|

|

Function

|

Cutting Metal Nonmetal Materials

|

|

Cutting materials

|

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

|

|

Working area

|

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

|

|

Model

|

1390/1625/2030/More

|

|

Laser source

|

Raycus IPG NLIGHT Laser Source

|

|

Control system

|

CNCControl

|

|

Keyword

|

Laser Cuting Machine

|

|

Max cutting speed

|

80mm/min

|

Cutting Samples

OPTIC EXHIBITION

Certifications

Hot Searches