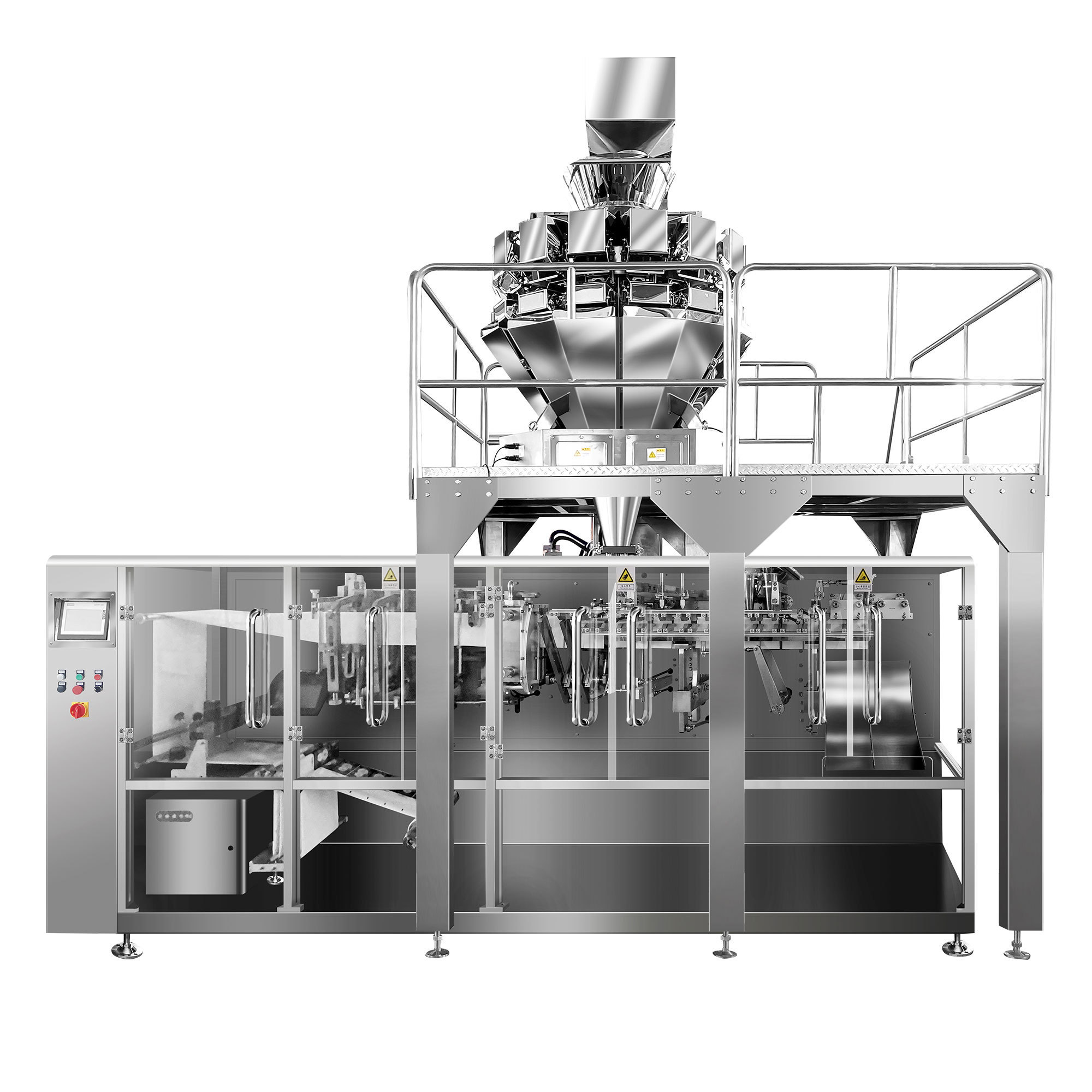

Huacheng HC-NG series is engineered in a simplified design with Linear module to fill Pre-made pouches from top and sealing in same machine.

It is equipped with a stainless steel, low maintenance and easy to change sizes, which moves the pouches through the station in a continuous motion.

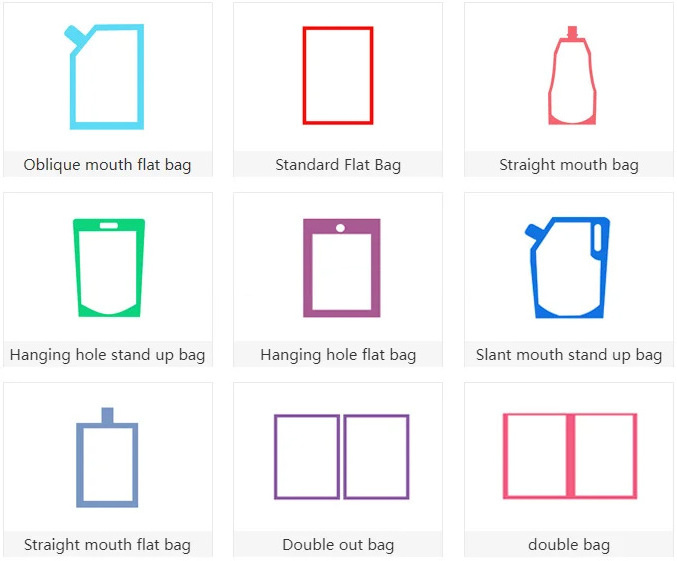

HC premade pouch packing machine has the wide range of different sizes and shapes in the market.

Our machines cover all the applications and are customized to be adapted to our customers' needs.

The design is based on the modular frame construction, composed of three independent modules: bag picking and dosing-sealing.

- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

120bag/min, 60bag/min

-

Weight (KG):

-

2000

-

Voltage:

-

220V/380V 50HZ

-

Place of Origin:

-

China

-

Brand Name:

-

Conoval

-

Dimension(L*W*H):

-

5200*1100*1460 MM

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Film

-

Packaging Material:

-

Plastic, Paper, Metal

-

Production Capacity:

-

120bag/min, 60bag/min

-

Weight (KG):

-

2000

-

Voltage:

-

220V/380V 50HZ

-

Place of Origin:

-

China

-

Brand Name:

-

Conoval

-

Dimension(L*W*H):

-

5200*1100*1460 MM

Products Description

Horizontal flexible premade bag pouch packing machine

Technical Parameters

|

Simplex model

|

180NG

|

210NG

|

240NG

|

280NG

|

330NG

|

|

Min(W*H)

|

65×130mm

|

90×130mm

|

110×140mm

|

120×150mm

|

110×150mm

|

|

Mix(W*H)

|

180×250mm

|

210×330mm

|

240×350mm

|

280×400mm

|

330×500mm

|

|

Packing volume(Max)

|

1000ml

|

1500ml

|

2000ml

|

3000ml

|

4000ml

|

|

Speed(Bag/min)

|

≤60

|

≤60

|

≤60

|

≤45

|

≤40

|

|

Machine sizes

(L*W*H) |

2400×980×1400

|

2550×1100×1400

|

2760×1100×1400

|

2900×1100×1400

|

3475×1215×1600

|

|

Weight

|

1100kg

|

1200kg

|

1400kg

|

1500kg

|

1800kg

|

|

Temperature

|

-10ºC-+55ºC

|

-10ºC-+55ºC

|

-10ºC-+55ºC

|

-10ºC-+55ºC

|

-10ºC-+55ºC

|

|

Moisture

|

below 85%

|

below 85%

|

below 85%

|

below 85%

|

below 85%

|

|

Voltage

|

AC380V,50Hz

|

AC380V,50Hz

|

AC380V,50Hz

|

AC380V,50Hz

|

AC380V,50Hz

|

|

Pressure

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

|

Air

|

300L/min

|

300L/min

|

350L/min

|

350L/min

|

400L/min

|

|

Power

|

3.5Kw

|

4.5Kw

|

5.5Kw

|

5.5Kw

|

5.5Kw

|

Duplex model , packing double bags per time:

|

Duplex model

|

180DG

|

210DG

|

240DG

|

280DG

|

330DG

|

400DG

|

460DG

|

|

Min(W*H)

|

65×130mm

|

65×130mm

|

90×140mm

|

90×140mm

|

90×140mm

|

100mm×200mm

|

100x150mm

|

|

Mix(W*H)

|

90×250mm

|

105×250mm

|

120×330mm

|

140×400mm

|

160×450mm

|

180mm×300mm

|

215x350mm

|

|

Packing volume(Max)

|

300ml

|

400ml

|

500ml

|

700ml

|

1000ml

|

1000ml

|

2000ml

|

|

Speed(Bag/min)

|

≤120

|

≤120

|

≤120

|

≤100

|

≤80

|

≤80

|

40-60

|

|

machine sizes

(L*W*H) |

2400×1100×1400

|

2550×1100×1400

|

2760×1100×1400

|

2900×1100×1400

|

3475×1215×1600

|

4200×1100×1400

|

5360x1050x1500

|

|

weight

|

1100kg

|

1200kg

|

1400kg

|

1500kg

|

1800kg

|

2000kg

|

2500kg

|

|

temperature

|

-10℃—+55℃

|

-10℃—+55℃

|

-10℃—+55℃

|

-10℃—+55℃

|

-10℃—+55℃

|

-10℃—+55℃

|

-10℃—+55℃

|

|

moisture

|

Less than 85%

|

Less than 85%

|

Less than 85%

|

Less than 85%

|

Less than 85%

|

Less than 85%

|

Less than 85%

|

|

voltage

|

AC380V、50Hz

|

AC380V、50Hz

|

AC380V、50Hz

|

AC380V、50Hz

|

AC380V、50Hz

|

3P、AC220V、60Hz

|

AC380V、50Hz

|

|

pressure

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

|

air

|

300L/min

|

300L/min

|

350L/min

|

350L/min

|

400L/min

|

600L/min

|

400L/min

|

|

power

|

3.5Kw

|

4.5Kw

|

5.5Kw

|

5.5Kw

|

5.5Kw

|

8Kw

|

9.5Kw

|

Our Advantages

1) HMI Display includes instruction manual and troubleshooting

2) Parallel motion of the vertical sealing bars enables for improved sealing quality and easier maintenance.

3) Full servo motion : This smart servo-control system allows independent operation between the different stations, offers great reliability and little maintenance.

4) Walking beam: transport system consisting of beams and grippers. They hold the pouches and transport them through the different stations, from the pouch forming to the pouch closing.

5) Multiple steps of sealing are needed to guarantee sealing quality

6) filling : allow hot and cold filling

2) Parallel motion of the vertical sealing bars enables for improved sealing quality and easier maintenance.

3) Full servo motion : This smart servo-control system allows independent operation between the different stations, offers great reliability and little maintenance.

4) Walking beam: transport system consisting of beams and grippers. They hold the pouches and transport them through the different stations, from the pouch forming to the pouch closing.

5) Multiple steps of sealing are needed to guarantee sealing quality

6) filling : allow hot and cold filling

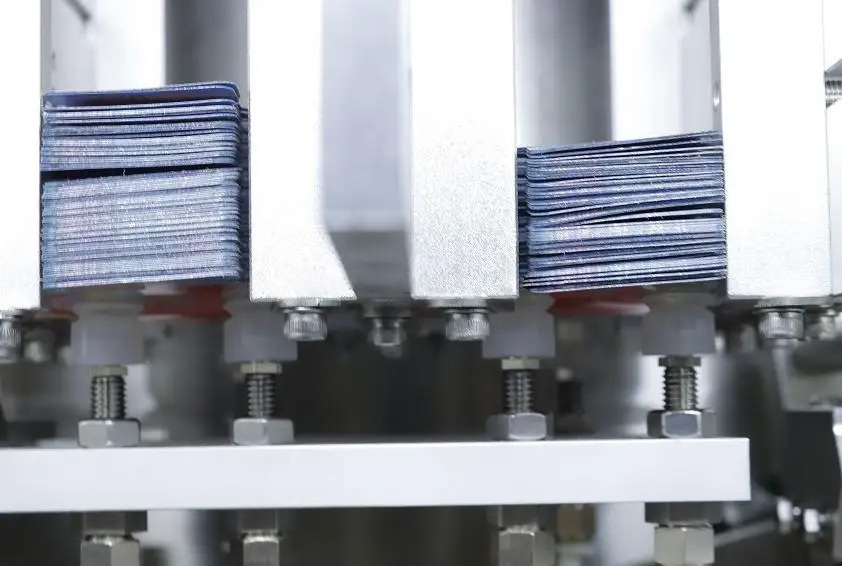

1. Independent bag picking:1.picking fast and stable 2.easy to change sizes 3.non-stop machine adding pouches

2. Bag stretching :1. wrinkle-free. 2. structure compact and easy to adjust.

3. High accuracy,smooth and clean filling for powder,liquid and granule

4.double cold sealing + hot sealing ,sealing tight and smoothing

|

1.coding

|

cold press code or touch code form, date QR code, bar code can be realized

|

|

2.easy notch

|

easy notch cutting

|

|

3 Hanging hole

|

round hole or euro hole

|

|

4.independent film frame

|

Independent doypack bag forming advice

|

|

5.film align(optional)

|

align film automatically

|

|

6.top spout (optional)

|

adding top spout inserting station

|

|

7.corner spout (optional)

|

adding corner spout inserting station

|

|

8.double time filling

|

increase the speed by double-head filling for big package

|

|

9.bag support

|

adding bag support for big package

|

|

10 conveyor

|

select the finished product conveyor belt to transport

|

Hot-selling Product

Our Service

Why Choose Us

Satisfying Your Needs

As a mechanical company with 15 years of manufacturing experience and 10 years of export experience, we have achieved an export volume of over 10 million US dollars, covering more than 30 countries. With a team of over 20 professional R&D talents and multiple national patents, we are committed to technological innovation. As a leading manufacturer in the industry, we strive to provide excellent products and top-notch services, tailored to meet our customers' needs.

Quality and Safety

We are a foreign trade company that specializes in mechanical products and places great emphasis on product quality and safety. Our products are protected by the latest and strictest patent standards and meet various international inspections, certifications, and standards, such as CE, UL, and GMP. With customer needs at the forefront, we strive to provide high-quality products and excellent after-sales service, and work closely with our customers to establish long-term cooperation.

Logistics and Delivery

FAQ

FAQ

If you can't find the answer to your concern, contact us immediately and enjoy our service now.

Q:Do you have any guarantee for the product quality?

A: Yes, we have a sound quality control system and ensure that each product undergoes strict inspection to ensure that the product quality meets our standards and customer requirements. If customers find quality problems after receiving the products, we will promptly handle and compensate.

Q:Do your products meet international quality standards?

A: Yes, our products meet international quality standards and have passed the corresponding certifications. We will list the relevant certification information in the product specifications.

Q:What kind of packaging protection do you provide during transportation?

A: We will adopt different packaging methods to ensure product safety based on different products and transportation methods. Generally, we use durable packaging materials and methods to ensure the products are not damaged during transportation.

Q:What is your general delivery time?

A: The delivery time will vary according to the specific order requirements. We will do our best to ensure that the order can be delivered on time, and communicate the expected delivery time with the customer immediately after order confirmation.

Q:Can you provide customized services if I have specific needs?

A: Yes, we can provide customized services. We will formulate corresponding plans based on the customer's needs

to meet their special requirements.

Q:Do you provide technical support and after-sales services?

A: Yes, we provide professional technical support and after-sales services. We will provide timely and professional assistance to customers for any problems that may arise during product use or for technical support.

Q:What payment methods do you accept?

A: We support multiple payment methods, such as TT, LC, Western Union, etc. We will communicate with the customer and negotiate the most suitable payment method after order confirmation for both parties.

Q:How can I obtain more detailed product information?

A: You can obtain more detailed product information through our official website or by contacting our sales staff. Our sales staff will provide the most professional consultation and advice based on your needs.

Q:Do you have any other customer experience sharing or case introductions?

A: Yes, we can provide other customer experience sharing or case introductions. This information can provide customers with more references and helpful insights.

Hot Searches