- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

65 rpm

-

Place of Origin:

-

Qingdao City,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

12mx3mx2m

-

Power (kW):

-

40

-

Weight:

-

2000 KG

-

Name:

-

Extrusion Machine

-

Final product:

-

single wall corrugated pipe

-

Pipe diameter:

-

6-300

-

Usage:

-

PP/PE/PVC single-wall corrugated pipe extrusion machine

-

Raw material:

-

PP PE PVC

-

After-sales Service Provided:

-

Video technical support, Free spare parts,Training

-

Key words:

-

Pipe Machine Production Line

-

Motor:

-

SIEMENS Brand

-

Processing Type:

-

Pipe Exturding Machine

-

Product Type:

-

Single Wall Corrugated pipe

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

45,65,90,120

-

Screw Speed (rpm):

-

65 rpm

-

Place of Origin:

-

Qingdao City,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

12mx3mx2m

-

Power (kW):

-

40

-

Weight:

-

2000 KG

-

Name:

-

Extrusion Machine

-

Final product:

-

single wall corrugated pipe

-

Pipe diameter:

-

6-300

-

Usage:

-

PP/PE/PVC single-wall corrugated pipe extrusion machine

-

Raw material:

-

PP PE PVC

-

After-sales Service Provided:

-

Video technical support, Free spare parts,Training

-

Key words:

-

Pipe Machine Production Line

-

Motor:

-

SIEMENS Brand

-

Processing Type:

-

Pipe Exturding Machine

-

Product Type:

-

Single Wall Corrugated pipe

Product Description

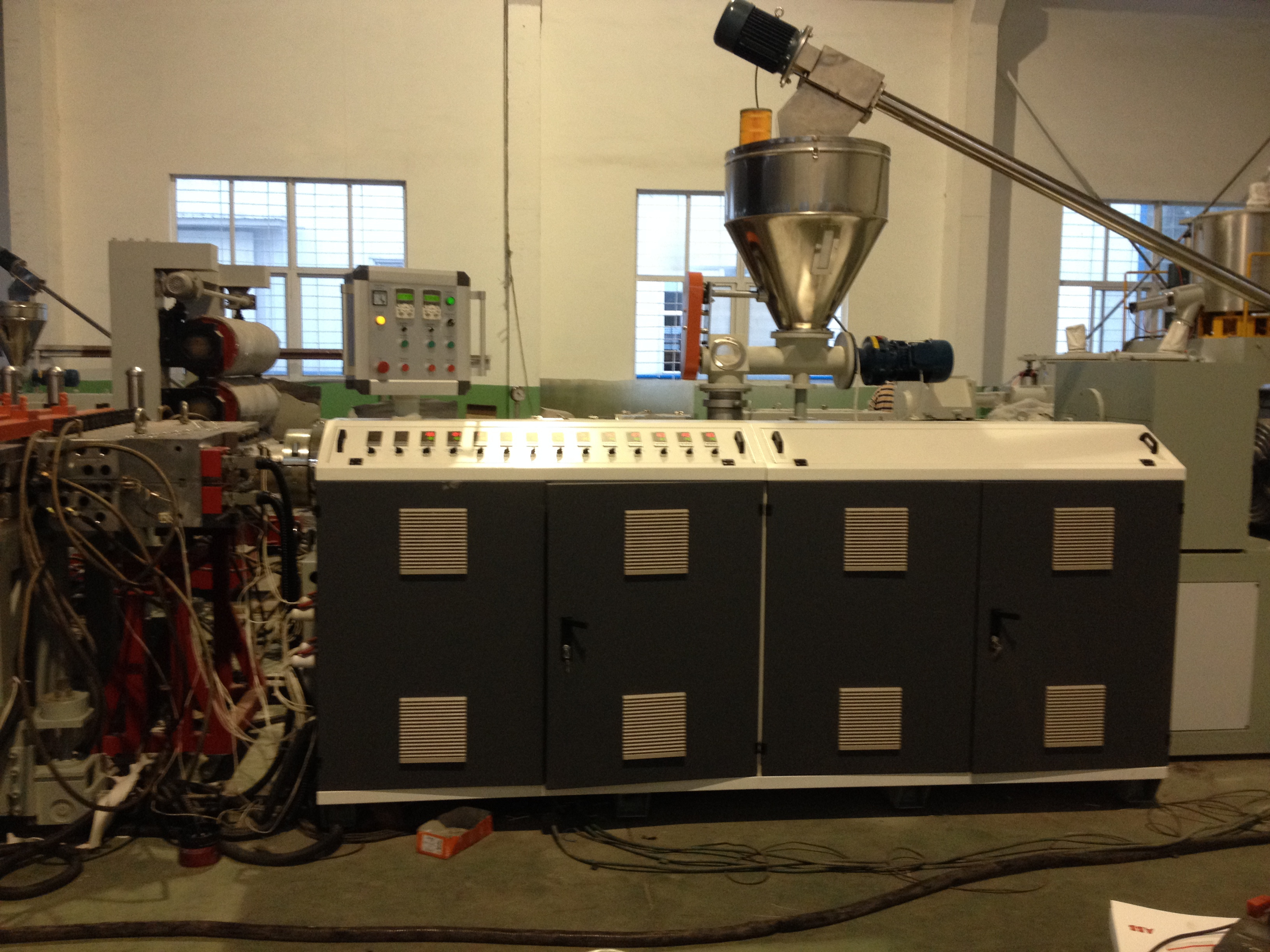

---High Speed Plastic Corrugated Pipe Making Machine/pe Pp Pvc Single Wall Corrugated Pipe Making Machine

---Depending on the type of raw material to be used, this extrusion system offers either single or twin screw extruder,PVC used to It can continuously extruding various sizes of corrugated pipes.

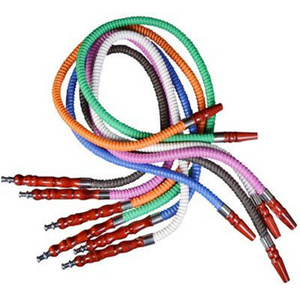

---These corrugated pipes are especially used as wires of up-market cars,cable protection pipe,water smoking pipe and so on.

--- Performance characteristics:

1.High speed single/twin screw extruder with channeled cylinder, high efficiency extrusion guaranteed. Strong cooling waved shaping system is installed within the extrusion system, provide high speed extrusion, size precision and stable quality;

2.High quality of mold alloy to make the molds, high hardness and toughness, abrasion resistance, and great heat dissipation;

3.Varity of shaping molds to choose from,uncommon shape can be specifically designed.

4.Advanced on-line opening enlarging machine, pipes not be enlarged during the extruding process.

5.Fully automatic control system

---Production speed :20-35m/min.

|

NO

|

Name

|

Qty

|

|

1

|

Vacuum feeder and hopper dryer

|

1set

|

|

2

|

SJ65/30 Single Screw Extruder

|

1set

|

|

3

|

New Design Die head

|

1set

|

|

4

|

Mouth mould、core bar、gas nose and pull rod

|

1set

|

|

5

|

Corrugated pipe forming mould

|

1set

|

|

6

|

High speed forming machine

|

1set

|

|

7

|

Double station winding machine

|

1set

|

Application

Plastic single wall corrugated pipes have features of high temperature resistance, resistant to corrosion and abrasion, high

intensity, good flexibility. Which are widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine.

intensity, good flexibility. Which are widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine.

Specification

|

Model

|

Pipe Diameter(mm)

|

Extruder Model

|

Hall-off speed(M/min)

|

Total Power(Kw)

|

|

DBG-10

|

6-10

|

SJ-45/28

|

1-20

|

45

|

|

DBG-25

|

8-20

|

SJ-45/28

|

1-15

|

50

|

|

DBG-63

|

16-90

|

SJ-65/30

|

1-10

|

70

|

|

DBG-200

|

110-200

|

SJ-90/30

|

1-5

|

88

|

|

DBG-300

|

160-300

|

SJ-120/30

|

0.5-4

|

130

|

Detailed images

Products process:

Single screw extruder---

Die head---

Vacuum calibration cooling tank---

Spraying water tank---

Caterpillar Hall-off machine---

Automatic pipe cutting machine---

Stacker

Single screw extruder

The extruder is consist of screw, barrel, vacuum automatic feeder, hopper dryer, gearbox and motor. Spiral screw with mixing section, which improve the output and plasticization quality. Special for PE\PP\PET\ABS material efficient extrude. Water cooling system with automatic temperature control is at the material inlet port of the barrel. The vacuum automatic feeder adopts inductive design with material shortage alarm function. The hopper dryer adopts drying and storing material integrated design,also with automatic temperature control and intelligent display. The gearbox equips with force lubrication system and external cooling water circulation system. It connects with motor directly, so better deceleration effect. Long service span, low noise and low heating. All the parts be made by reputed manufacturer and provided by reputed supplier.

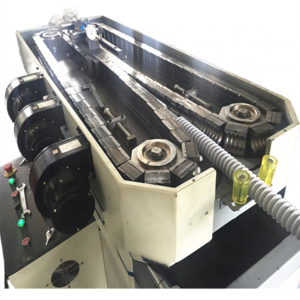

Corrugated pipe molds

----We can design and process normal corrugated pipe mold blocks, joint corrugated pipe mold blocks and other types corrugated pipe mold blocks according to customer's requirements.

----All the modle blocks are specialized mold steel, which is of high hardness and strong wear resistance.

Forming machine and Forming mould

----High speed forming speed:20-35 m/min.

----The forming machine plate and high speed forming mould use 38CrMoAIA material,has high hardness, high wear resistance.and the forming mould can carve customer logo,can choose double cavity or three cavity in one set mould,when change the size,just up and down forming machine,no need put out all set mould. it can save more long time for customer.

----

The forming machine equips with one set vacuum bump and vacuum system. Specially designed for shisha hose/magic pipe/joint corrugated pipe.

----Forming machine adjustment:manual control left and right,Electric control up and down.

Corrugated pipe automatic coiler

----It includes single position automatic coiler and double position automatic coiler.

Double station winding machine

----

Automatic wiring device,balance the speed match rewinding speed,help winding machine adjust the speed,when the pipe production slow,will stop rewinding,prevent pipe too tight disconnect.

Hot Searches