- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

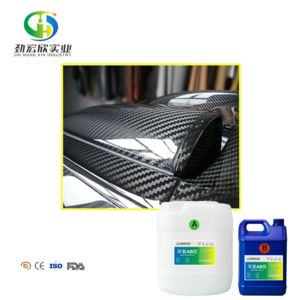

Carbon Fiber laminating Epoxy Resin

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SANDOZ

-

Model Number:

-

SAN-EPC2

-

Type:

-

Liquid Glue

-

Color:

-

Transparent

Quick Details

-

CAS No.:

-

Carbon Fiber laminating Epoxy Resin

-

Other Names:

-

Carbon Fiber laminating Epoxy Resin

-

MF:

-

Carbon Fiber laminating Epoxy Resin

-

EINECS No.:

-

Carbon Fiber laminating Epoxy Resin

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SANDOZ

-

Model Number:

-

SAN-EPC2

-

Type:

-

Liquid Glue

-

Color:

-

Transparent

Our Resin System is a high quality resin which is popular for lamination with fiberglass, carbon fiber, kevlar or any type of reinforcement. The syrup-like consistency will generate fast wet-out and easy application of any reinforcement. We recommend choosing your hardener below based on your temperature, curing thickness, desired working time and desired drying times. This Resin System will produce a low viscosity, crystal-clear, low odor epoxy that is not only ideal for layup use, but also as a sealer of porous substrates such as wood because of its penetrating power. You can easily make an adhesive, fairing putty or filler when combining the Resin System with a product from our selection of powder fillers.

# Resin Viscosity: 600 cps

# Epoxy resins require a hardener to initiate curing which is included in the kit.

# Thin Resin can be used with your choice of 3 different hardeners.

# To Determine Final Volume, add the resin and hardener amounts given

* Non Blushing * Mixing Ratio by Volume: 2:1

* Pot Life: 45-50 Min @ 80F

* Set Time: 5-6 Hours

* Drying Time: 24-28 Hours

Kit Pricing Includes RESIN and HARDENER

Pumps can also be purchased separately

Description of Epoxy Hardeners:

All working times(pot life) are based upon an optimum working temperature of about 80 degrees F. Temperatures variations will greatly affect curing times, and when below 65F can sometimes double curing times. Other factors that affect epoxy curing can be moisture and humidity, as well as the thickness of lamination.

Description of Times Shown:

* Pot Life: Represents the maximum amount of time that the mixture can remain in your pot. Once applied to your working surface(usually in thin layers) this will greatly increase the time you have before the epoxy sets.

* Set Time: This is the amount of time after the epoxy is applied in a thin film that it will arrive at a gel state, still wet, but no longer a liquid. To recoat without sanding between coats you must reapply after this point but before the drying time has completed.

* Drying Time: At this point the epoxy will be ready to sand and has reached about 90% of its cured hardness. Epoxy still might remain a bit flexible at this point but will complete 100% curing over the following 1-5 days.

NOTE: Our slow hardener should only be used at temperatures above 80degrees unless an extremely long curing time is desired. Temperatures below 70F during the cure can result in a 2-3 day drying time.