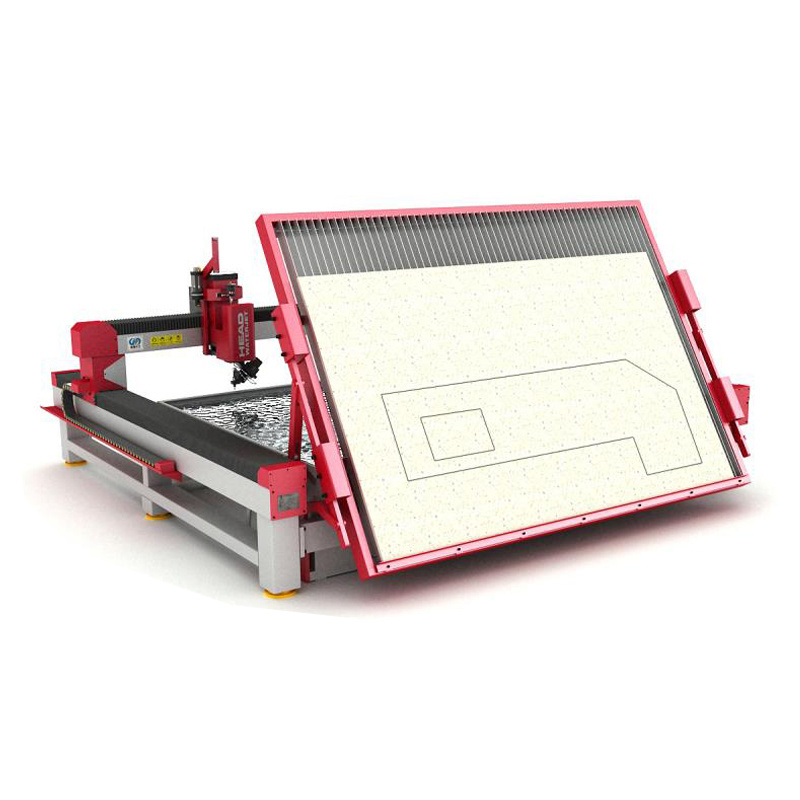

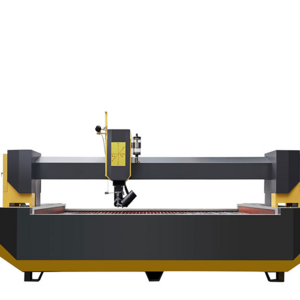

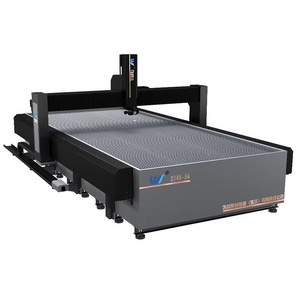

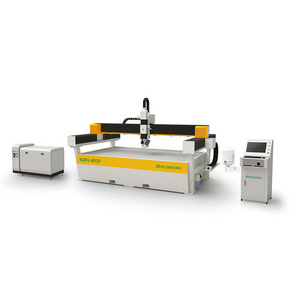

Waterjet Cutting Systems / cnc Waterjet Cutting machine

we produce for our customers the most different waterjet machines – also called waterjet cutters or water jet.

A waterjet cutting system performs demanding tasks in

nearly all industries

. It enables

extremely fine, precise cuts on sensitive

, hard and soft materials as well as on non-metals such as

Stainless steel,

aluminum, copper

,

iron and steel

,

marble

,

alloy metal

,

glass

,

plastic

,

ceramic,

tile

and all kinds of visible

materials that you can see in our daily life .

When mixed with fine abrasive sand, a waterjet cutting system also cuts enormous material thicknesses without changing the material structure in the cutting area.

Why HEAD Waterjet

It is the fastest growing precision machine process that is environmentally friendly with great efficiency and productivity.

Waterjet cutting technology has taken over due to the fact there no limits to what waterjets can cut. It’s a process that does not require tool sharpening and it cuts with great accuracy leaving clean and smooth edges.

Tips:The Cutting platform size and other parts all can be customized