- Product Details

- {{item.text}}

Quick Details

-

Function:

-

Printing Slotting Die Cutting Optional

-

Automatic grade:

-

Full-Automatic

-

Plate Type:

-

Letterpress

-

SPEED:

-

200PCS/min

-

Feeding way:

-

Lead Edge Feeder

-

Voltage:

-

220/380/400/440V

-

Printing color:

-

123456 colors

-

Usage:

-

Paperboard Corrugated Carton Box Making

-

Printing Plate Thickness:

-

7.2mm

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HUALI

-

Application:

-

anvil cover die cutting machine

-

Function:

-

Printing Slotting Die Cutting Optional

-

Automatic grade:

-

Full-Automatic

-

Plate Type:

-

Letterpress

-

SPEED:

-

200PCS/min

-

Feeding way:

-

Lead Edge Feeder

-

Voltage:

-

220/380/400/440V

-

Printing color:

-

123456 colors

-

Usage:

-

Paperboard Corrugated Carton Box Making

-

Printing Plate Thickness:

-

7.2mm

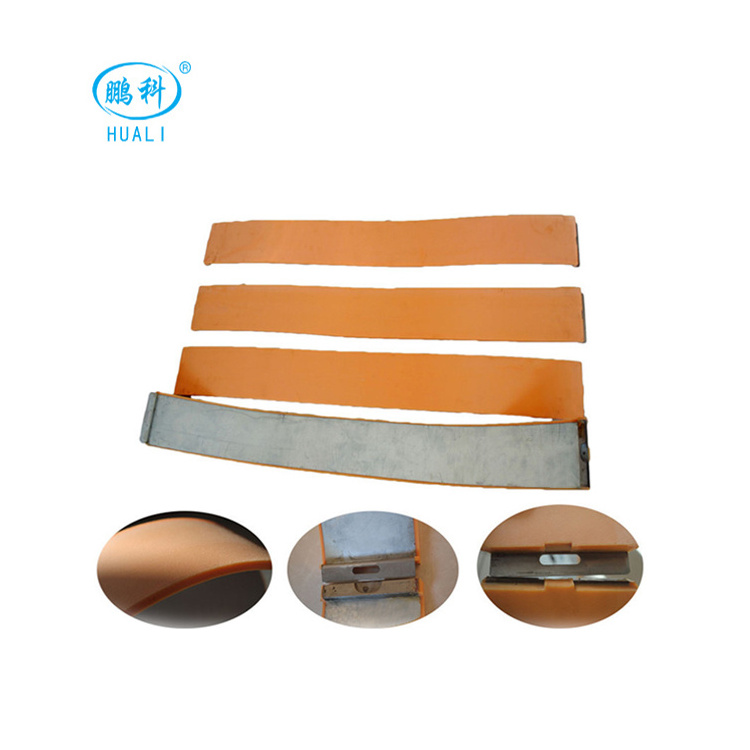

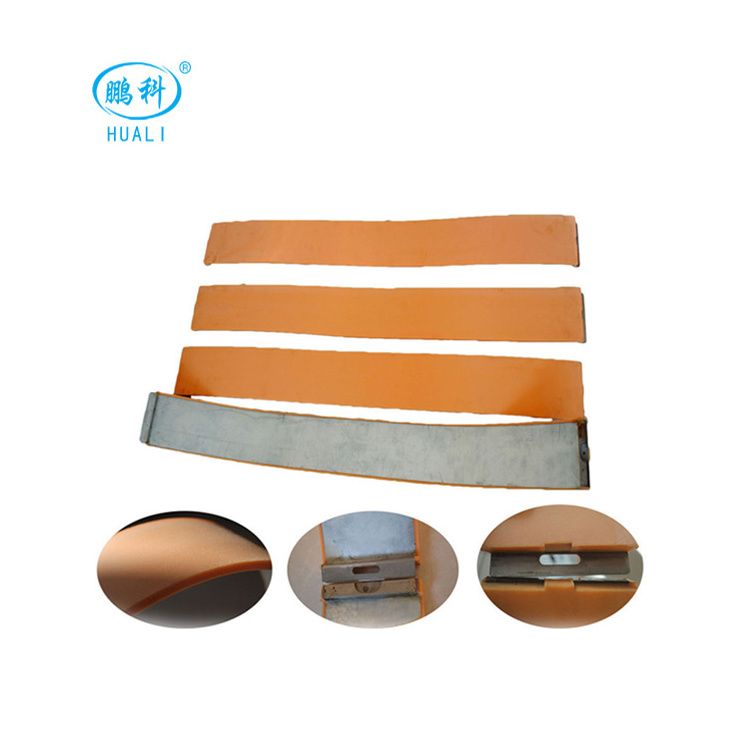

Maxdura Rubber anvil cover die cutting roller machine

Product Features:

1, with a strong die-cutting surface, in the process of die-cutting is not easy to produce scratches, in the process of high-speed die-cutting operators only need to minimize the die-cutting Pressure, you can get clean die-cutting products, so as to improve the service life of die-cutting machine and rubber pad.

2. The surface is ground and has a uniform thickness, so as to ensure the precision of the rubber pad after installation and its fitting character and stability in the process of use.

3, the inner steel plate structure, avoid in the process of high speed die-cutting rubber pad deformation, to ensure the quality of die-cutting.

4, with a variety of different specifications, can meet the needs of customers in the shortest time.

5, with double width rubber pad choice, can reduce joints, improve the precision of die cutting.

Usage Suggestion:

1, choose high quality imported knife, according to die cutting products choose die cutting knife tooth shape.

2, choose high-quality waste sponge, according to the die-cutting products to match the height and thickness of the indentation steel line.

3, every time after the replacement of a new rubber pad, the distance between the die-cutting cylinder and the rubber pad cylinder must be adjusted to the initial position. Gradually increase the pressure until just enough to cut the whole piece of paper. The lower the pressure, the longer the life of the rubber pad.

4. There are some places that are not easy to cut off for the newly installed rubber mat and the replacement mold, so excessive pressure should not be added. The bottom pad of the mold blade should be raised to cut off.

5, in the process of using the die cutting high-speed operation, auxiliary die cutting accessories easy to lose need to replace or supplement in time.

6, the mold can be changed according to the actual situation and die cutting product requirements, die cutting board replacement die cutting knife times can not be more than twice.

7, die cutting knife and spring pad need to be replaced in time, life in 150,000 to 300,000 times need to be replaced, and make a good record every time.

| Rubber width | 125mm |

| Rubber width | 250mm |

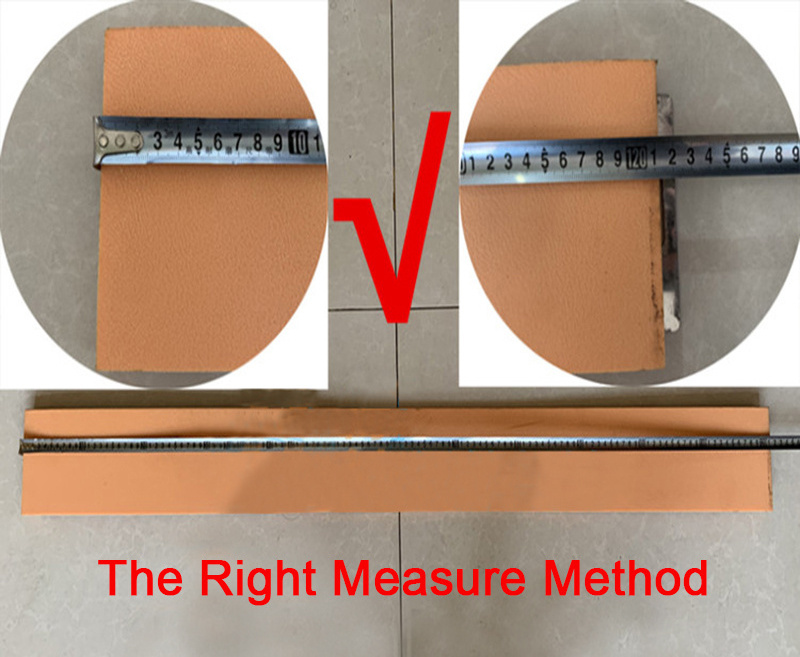

How to measure my size?

Answer: the best and most accurate method is to put the rubber mat down on the ground tile, (pay attention to must tile, warping can not) measure the net length of the rubber surface, (not steel plate surface is not the total length of the buckle, is the total length of the glue surface, horse tooth buckle measurement method is also different, consult customer service understanding. Then measure the width can be, general four-die cutting width 125mm rotary die-cutting width 250mm, some four-die cutting after a long time to use the measured width is 130m, the actual purchase of 125mm width can, because after a long time to press and cut both sides wide a few millimeters is a normal phenomenon!

The Die cutting anvil cover used on ourself machine: