Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

45 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380V,50HZ,3P

-

Dimension(L*W*H):

-

depend on model

-

Weight:

-

2.5 KG

-

Diameter of screw:

-

45,65

-

Number of screw:

-

1

-

Length and diameter ratio:

-

Customized

-

Material of wcrew:

-

38CrMoA1A

-

center height:

-

1000mm or Customized

-

Screw edge surface roughness:

-

0.4μm

-

barrel inside surface roughness:

-

0.8μm

-

Depth of nitride for cylinder and screw:

-

0.5~0.7mm

-

gearbox:

-

hard teeth face inclined gear reducer

-

application:

-

PP melt-blown fabric

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw diameter (mm):

-

45 mm

-

Screw Speed (rpm):

-

45 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380V,50HZ,3P

-

Dimension(L*W*H):

-

depend on model

-

Weight:

-

2.5 KG

-

Diameter of screw:

-

45,65

-

Number of screw:

-

1

-

Length and diameter ratio:

-

Customized

-

Material of wcrew:

-

38CrMoA1A

-

center height:

-

1000mm or Customized

-

Screw edge surface roughness:

-

0.4μm

-

barrel inside surface roughness:

-

0.8μm

-

Depth of nitride for cylinder and screw:

-

0.5~0.7mm

-

gearbox:

-

hard teeth face inclined gear reducer

-

application:

-

PP melt-blown fabric

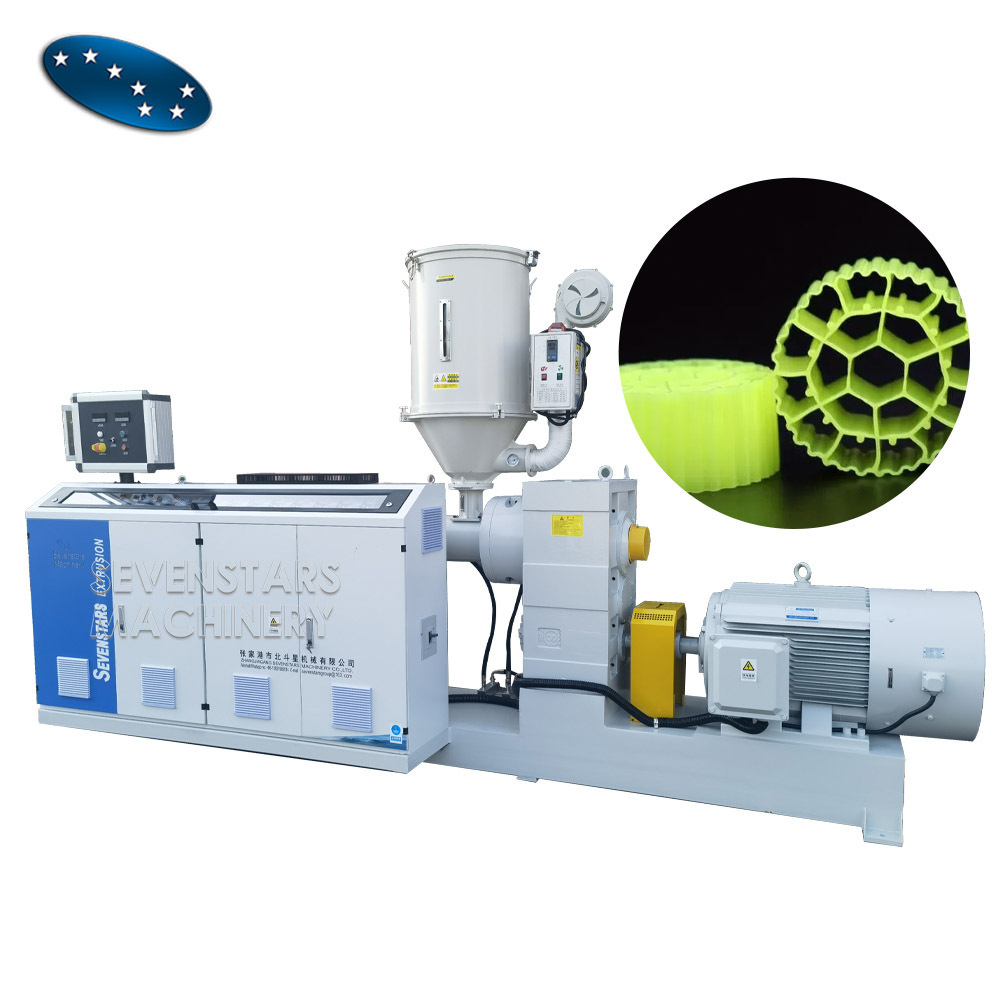

Single screw plastic extruder production line

Working principle

The polypropylene raw material is put into the extruder, after melting between the screw and the barrel, it is transported to the melt pump and the filter, after filtering, it is quantitatively sent to the spinneret assembly. At this time, the hot air flow on both sides of the spinneret hole blows out the melt material at a speed close to the speed of sound, so that it is quickly thinned, and in the falling process, it is cooled and solidified by the traction air flow on both sides.

Main model

| Item | Power | output |

| SJ45 | 15KW | 30kg/h |

| SJ65 | 37KW | 80kg/h |

Hot Searches