- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huahong

-

Dimension(L*W*H):

-

1667*1545*1020mm

-

Weight:

-

3.6 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Favorite

-

After sale Service:

-

Overseas

-

Installation:

-

Under Engineer's Guide

-

The Machines classification:

-

Small Stone Machine

-

Product name:

-

Widely-used Mining Equipment

-

Spare parts supply:

-

12 Months Guarantee

-

Max feed lump size:

-

125mm

-

Adjustment range:

-

10-40mm

-

Maine shaft speed:

-

300r/min

Quick Details

-

Application:

-

Mining,building,chemical,highway

-

Capacity(t/h):

-

5-15m3/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huahong

-

Dimension(L*W*H):

-

1667*1545*1020mm

-

Weight:

-

3.6 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Favorite

-

After sale Service:

-

Overseas

-

Installation:

-

Under Engineer's Guide

-

The Machines classification:

-

Small Stone Machine

-

Product name:

-

Widely-used Mining Equipment

-

Spare parts supply:

-

12 Months Guarantee

-

Max feed lump size:

-

125mm

-

Adjustment range:

-

10-40mm

-

Maine shaft speed:

-

300r/min

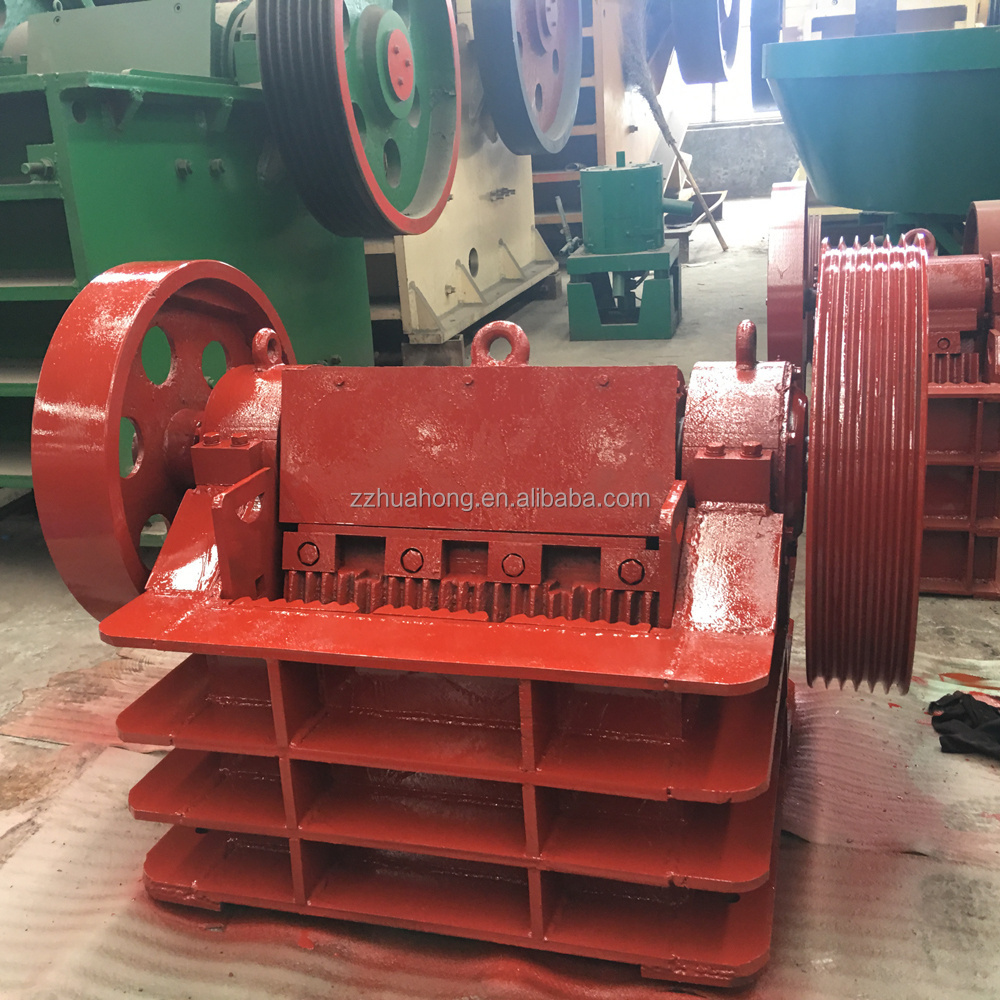

Jaw crusher for secondary crushing

1.Stone Crushers is mainly used for the medium and fine crushing of hard ores and rocks in metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry and ceramic industry and other sectors.

2. Stone Crushers is suitable for crushing all kinds of hard and soft ores with less than 320MPa compressive strength, such as pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, ore, glass, cement clinker, etc.

3. We have improved the design of V-shape jaw crusher. Its front wall is changed to taper type, the feeding inlet is changed into V-shape. The movement is also changed slightly, thus the crushing stroke is increased, and the output capacity is also increased 20%.

Our advantages:

-The deep crushing cavity increases the feeding capacity and output capacity;

-High ratio of crushing, homogeneous final product size;

-Adjusting the discharge opening through gasket, more convenient, it can meet different customers’ requirement

-system is safe and reliable, easy to change the spare parts;

-Simple structure, easy maintenance, consumption cost is lower;

-Energy-saving, for one set saving about 15%-30%;

-Less noise and dust.

Detailed parameters of the Jaw Crusher:

|

Model

|

Power

(Kw)

|

Capacity

(t/h)

|

Rotor Speed

(r\min)

|

Max Feeding

Size(mm)

|

Discharge Size

(mm)

|

Overall Dimensions

(mm)

|

|

PE250×400

|

18.5

|

5-20

|

280-320

|

220*380

|

30-120

|

1150×1275×1240

|

|

PE300×500

|

22

|

8-40

|

280-300

|

270*480

|

35-130

|

|

|

PE400×600

|

30

|

12-50

|

280-300

|

320*530

|

35-140

|

1700×1732×1653

|

|

PE400×600

|

30

|

15-60

|

280-300

|

350*580

|

40-150

|

|

|

PE500×750

|

55

|

30-112

|

250-280

|

450*730

|

50-180

|

2035×1921×2000

|

|

PE600×900

|

55-75

|

50-190

|

250-275

|

550*850

|

80-200

|

2290×2206×2370

|

|

PE750×1060

|

110-132

|

100-280

|

250-275

|

650*1010

|

90-250

|

2620×2302×3110

|

|

PE900×1200

|

132-160

|

200-500

|

220-250

|

750*1100

|

120-300

|

3789×2826×3025

|

|

PE1000×1200

|

132-160

|

300-600

|

200-250

|

850*1100

|

200-320

|

3335×3182×3025

|

|

PE1200×1500

|

160-185

|

400-800

|

180-220

|

1020*1400

|

200-350

|

4200×3750×3820

|

|

PEX150×750

|

22

|

12-35

|

280-350

|

210

|

25-60

|

1667×1545×1020 |

|

PEX250×1000

|

37

|

16-50

|

280-350

|

210

|

25-60

|

1560×2104×1415

|

|

PEX250×1200

|

45

|

20-60

|

280-350

|

210

|

25-90

|

1550×1964×1380

|

|

PEX350×750

|

37

|

16-50

|

280-350

|

300

|

30-100

|

|

|

PEX150×250

|

5.5

|

2-5

|

350-400

|

130*230

|

10-40

|

896×745×935

|

The working principle of jaw crusher

The motor drives the eccentric shaft to rotate by the V-belt & the slot wheel, then the movable jaw moves back and forth to break the materials in the crushing cavity which is composed of fixed jaw plate & movable jaw plate and side guard plate. When the movable jaw rises, the angle between the fixed jaw and movable jaw gets larger, and the materials can be broken to reach the crushing target. When the movable jaw is moving down, the angle between the fixed jaw and movable jaw becomes smaller .the end products slide from the discharge opening at the bottom.

|

|

|

Pre-sales service:

Be a good consultant and assistant to customers, to ensure our customer's investment rewarded with great profit.

1.Enough details about the materials shall be learned, sometimes a test is needed for some materials.

2. Equipment of right model is selected for customers.

3. Customized products and processing flow sheet can be designed and developed to meet customer's special needs,

4. Engineer could be sent to observe customer's working site to come up with an optimized solution accordingly.

On-sales service:

Every customer is respected and convenience and reliability will be provided. We are devoted to helping you to benefit as much as possible.

1. Inspection is a must before delivering of the goods.

2. Assistance to make a construction plan by supplying all drawings and data needed.

3. Most favorable scheme for you with the guaranteed quality.

4. Timely communication to make sure improvement of project and your requirement met.

After-sales service:

1. Installation, adjustment, and testing of equipment is available.

2. Train of technicians and workers at site is promised.

3. Service engineers will not leave until ensuring the whole line running well after the installation & adjustment is finished.

4.If any failure or question about the machines or the processing line, contact us and we are available at any time.

1. Over 12 years experience in jaw crusher and mining field.

2. CE ISO SGS certificates from official govement.

3. Fisrt-class pre-sales service and after-sales service.

4. 12 months warranty for complate machine.

5. Trade arrurance service.

6. Proffssional engineers team , design as your demands.

More details PLS click on http://zzhuahong.en.alibaba.com/

F A Q:

1.How is the quality of your product?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2.Guaranteed:

If product quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about Price?

Yes, we are factory and be able to give you the lowest price than market one, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.