- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

250000

-

Material:

-

Motor rotor, stator

-

Processing capacity:

-

500-2000kg/h

-

Recovery rate:

-

>98%

-

The purity of the output:

-

>99.8%

-

Application field:

-

Resource recycling industry

-

Equipment configuration:

-

conveying system, crushing system, magnetic separation system

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

SHUGUANG

-

Power (kW):

-

100

-

Weight (KG):

-

250000

-

Material:

-

Motor rotor, stator

-

Processing capacity:

-

500-2000kg/h

-

Recovery rate:

-

>98%

-

The purity of the output:

-

>99.8%

-

Application field:

-

Resource recycling industry

-

Equipment configuration:

-

conveying system, crushing system, magnetic separation system

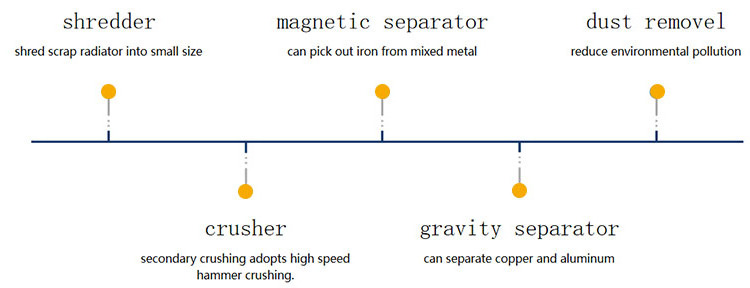

The new copper-aluminum water tank crushing and separation production line of waste air-conditioning radiator copper-aluminum separator is to recycle the copper-aluminum radiators dismantled from air-conditioners, generators, etc., and sort out the copper, iron, and aluminum among them. The radiator copper and aluminum water tank crushing and separation equipment is a combination of a series of equipment such as shredders, vertical composite crushers, magnetic separators, air separators, specific gravity separators, etc., to recover copper, iron, and iron in the radiator. aluminum. The radiator is put into the shredder, the shredded material is separated into iron by the magnetic separator, and then the remaining material enters the pulverizing system, and the pulverized material passes through the sorting system to separate copper and aluminum. The equipment is equipped with covered dust removal equipment, and the entire recycling process is clean and pollution-free. The separation rate of copper>98%, the separation rate of iron>99%, the separation rate of aluminum>98%

|

Processing diameter |

1m-1.5m |

|

Overall dimension(LXWXH) |

13mx16m |

|

Machine weight |

about 20t |

|

Motor voltage |

380V/220V |

|

Output/hour |

1000-2000kg |

|

Motor Power |

100-130kw |

Working principle:

1. Double-shaft shredder is a kind of low-speed and high-torque crushing equipment, which can squeeze, tear, and crush the radiator put into it to 5CM width and uneven length strip material. The shredded material can be Put it evenly into subsequent crushing equipment to improve crushing efficiency and increase output.

2. Through the high-speed rotation of the blades, the vertical crusher can produce impact and shear forces on the materials put into it, so that the materials can be crushed and crushed, and the materials of uniform particle size can be provided for subsequent sorting.

3. The air sorting machine can sort out most of the aluminum in the material to improve the sorting efficiency of the whole system. The air sorting machine is equipped with a fan. After the crushed material enters the air sorting machine, the density and the wind Under the action of, the lighter aluminum will fall farther inside the air separator, thereby separating most of the aluminum in the material.

4. The specific gravity separator is based on the specific gravity and suspension speed of the material. Under the action of airflow and vibration, the material is separated by the inclined surface of the material with certain movement characteristics. When the materials fall into the sorting machine, they are subjected to the effect of the inclined airflow, so that the materials with lighter specific gravity are automatically classified and kept in the upper layer, and the materials with heavier specific gravity are in the lower layer. Under the action of the exciting force, the two materials with different specific gravities are This kind of medium flows separately, thus realizing the separation of copper and aluminum.

Process flow:

Raw material And final product:

Click here for more information

1. The production line involves pretreatment, crushing, screening, and sorting in one go, and the connection is reasonable.

2. The waste radiator copper-aluminum water tank separator adopts PLC control, so that the system equipment can work in coordination and feed evenly.

3. Simple structure, reasonable layout; strong processing capacity, stable operation; sturdy and durable

4. High degree of automation and mechanized production can effectively reduce the intensity of manual production and save worry and effort.

5. The added value of treated copper and aluminum water tanks is increased, and iron, aluminum, and copper are sorted and recycled, which effectively improves the quality of materials and increases profit margins.

6. The dust removal rate of the pulse dust removal system reaches 99%, which effectively suppresses the dust overflow, fully meets the environmental protection requirements, and has no secondary pollution.