- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KX-MACHINERY

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1850*1050*1800MM

-

Motor Power (Kw):

-

7.5KW-90KW

-

Power (kW):

-

8.6KW-91.5KW

-

Weight (KG):

-

600 KG

-

Marketing Type:

-

New Product 2024

-

Application:

-

Make Biomass Fuel Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

80-120kg/h

-

Pellet size:

-

6/8/10/12mm Customized

-

After-sales Service Provided:

-

Commissioning

-

Advantage:

-

High Output

-

Length of Wood Pellets:

-

Adjustable Pellet Machine

-

Product name:

-

Wood Pellet Milling Machine

-

Color:

-

Customers' Request

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

80 - 1200 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KX-MACHINERY

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1850*1050*1800MM

-

Motor Power (Kw):

-

7.5KW-90KW

-

Power (kW):

-

8.6KW-91.5KW

-

Weight (KG):

-

600 KG

-

Marketing Type:

-

New Product 2024

-

Application:

-

Make Biomass Fuel Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

80-120kg/h

-

Pellet size:

-

6/8/10/12mm Customized

-

After-sales Service Provided:

-

Commissioning

-

Advantage:

-

High Output

-

Length of Wood Pellets:

-

Adjustable Pellet Machine

-

Product name:

-

Wood Pellet Milling Machine

-

Color:

-

Customers' Request

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

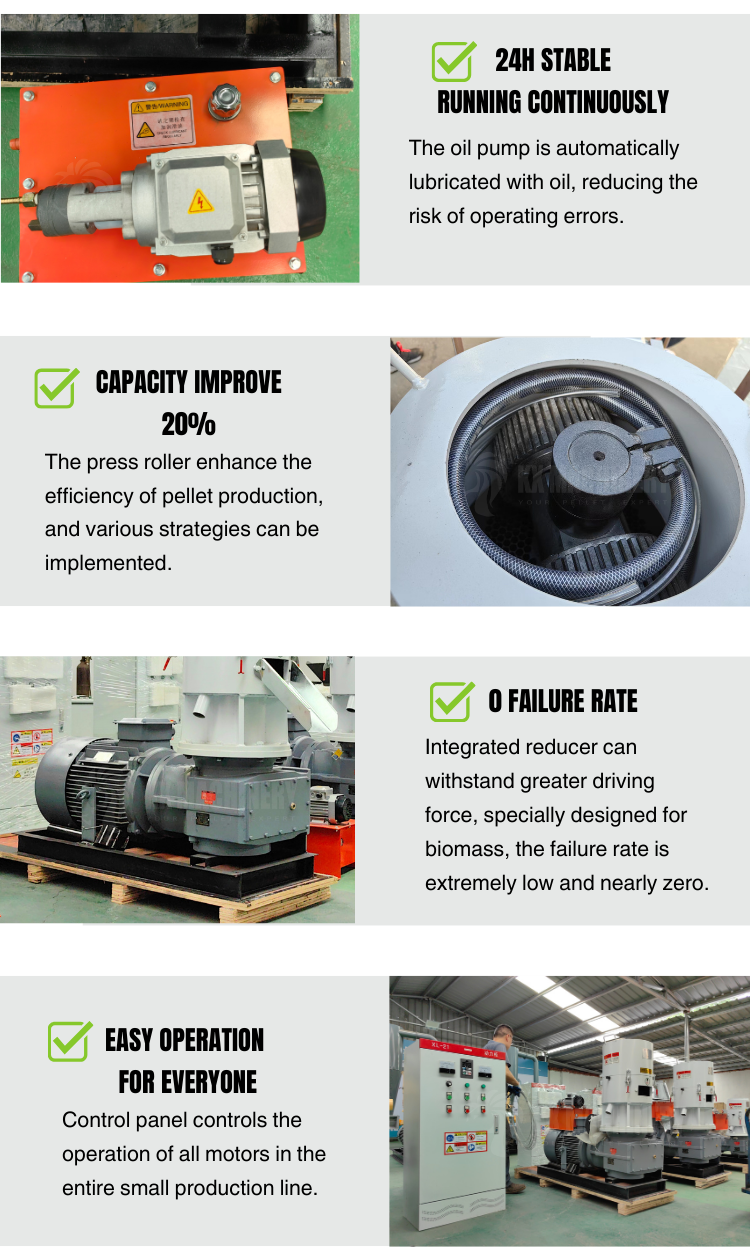

Small Biomass Pellet Machine for Home Use

20%

Capacity Improved

|

MODEL

|

MOTOR

|

CAPACITY

|

WEIGHT

|

|

F200

|

7.5KW

|

80-150kg/h

|

420kg

|

|

FD260

|

15KW

|

100-200kg/h

|

500kg

|

|

FD300

|

22KW

|

200-300kg/h

|

800kg

|

|

FD350

|

30KW

|

300-400kg/h

|

900kg

|

|

FD400

|

37KW

|

400-600kg/h

|

1000kg

|

|

FD450

|

45KW

|

600-800kg/h

|

1500kg

|

|

FD550A

|

55KW

|

700-1000kg/h

|

1800kg

|

|

FD550B

|

75-90KW

|

1000-1200kg/h

|

2300kg

|

Our biomass pellet machine is a versatile and robust solution designed to process a wide range of raw materials, including wood sawdust, oak sawdust, bagasse, fiber palm, straw, rice husk, grass, horse manure, chicken manure, and more. This advanced machine is engineered to efficiently convert these diverse feedstocks into high-quality pellets suitable for fuel, animal bedding, or other uses.

Adaptability

The machine can handle a variety of raw materials, from wood and agricultural residues to various types of manure, offering flexibility for different production needs.

High Efficiency

The machine is designed for optimal performance, ensuring high output rates and consistent pellet quality across different materials.

Energy Efficiency

With its advanced design, the machine minimizes energy consumption during operation, contributing to cost savings and environmental sustainability.

Durability

Constructed with high-quality materials and precision engineering, the machine offers long-lasting performance and reliability.

Ease of Operation

The machine features user-friendly controls and settings, making it simple for operators to adjust parameters for different types of feedstocks.

Customizable Pellet Sizes

The machine allows for adjustable pellet sizes, enabling users to tailor the output to their specific needs.

Our factory has a robust production capacity tailored to meet a variety of demands in the biomass industry. Utilizing advanced technology, we efficiently process various raw materials such as wood sawdust, oak sawdust, bagasse, fiber palm, straw, rice husk, grass, horse manure, chicken manure, and more.

Our facilities enable high-volume production of consistent, high-quality biomass pellets. A skilled workforce and rigorous quality control ensure all products meet industry standards. We excel in handling large orders and providing prompt delivery, making us a trusted partner for global customers with diverse needs.

Our

wood pellets machine 500- 1000kg hours

have garnered international acclaim, proudly exported to a multitude of countries, including Romania, Greece, India, Indonesia,Germany, New Zealand, and Chile and ect. Renowned for its exceptional quality and reliability, our product has earned the trust of customers worldwide. From the lush landscapes of New Zealand to the industrious markets of Germany and the dynamic energy sector of Chile, our pellet machine stands as a testament to superior engineering and craftsmanship. Its versatility and efficiency make it a sought-after solution for diverse biomass processing needs across continents. With a commitment to excellence and customer satisfaction, we continue to expand our global reach, delivering innovative solutions to every corner of the world.

1.

Do you provide after-sale service?

Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to solve your problems promptly and thoroughly.

2.How does a small home use pellet machine work?

A small home use pellet machine works by compressing raw materials, such as sawdust or wood chips, into compact pellets using pressure and heat generated within the machine.

3.What energy-saving features does your large pellet machine incorporate?

Our

home wood pellet machine

is engineered for optimal energy efficiency, minimizing power consumption while maximizing pellet output, resulting in both cost savings and environmental benefits.

4.How is the maintenance of the large pellet machine handled, and what support is available post-purchase?

We provide clear maintenance guidelines, and our after-sales support team is readily available to assist with any maintenance needs, ensuring ongoing efficient operation.

5.What types of raw materials can I use with a small home use pellet machine?

You can use various biomass materials such as sawdust, wood chips, straw, grass, agricultural residues, and even some types of animal feed.

6.What are the benefits of using pellets produced from a small home use pellet machine?

Pellets produced from a small home use pellet machine are eco-friendly, renewable, and can be used for heating, cooking, or as animal bedding. They are also convenient to store and transport, making them an ideal choice for home use.

Hot Searches