- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Suitable material:

-

CR, HR, stainless steel, galvanized steel, etc

-

Thickness:

-

depends on users

-

Width:

-

depends on users

Quick Details

-

Model Number:

-

SL

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LX

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Suitable material:

-

CR, HR, stainless steel, galvanized steel, etc

-

Thickness:

-

depends on users

-

Width:

-

depends on users

Description

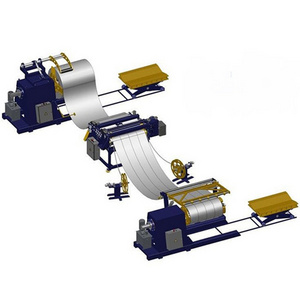

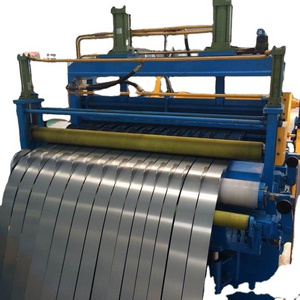

This slitting line is used for slitting raw material coils into strips. This machine can slit raw material coils into specific width. Our company has series of slitting lines, with thickness of 0.1-25mm and width up to 2500mm. The slitting line normally includes loading trolley, decoiler,guiding device (including lead roll, peleer table), coil head shear, centering and calibrating device, slitting machine, scrap rewinder, pre-distribution and tensioning machine, recoiler, and unloading trolley. The machine adopts PLC VF controlling system, DC driving for the slitting and recoiling, Touch screen operating and digital display. The production line is widely used for steel coil servcing for cold rolled steel, hot rolled steel, galvanized steel, stainless steel, etc.

Feature of the Machine

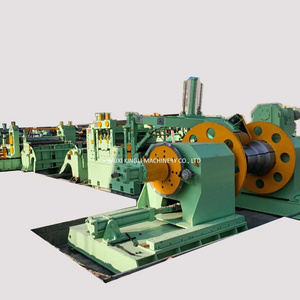

1. Double cone heavy duty decoiler, capacity up to 20, 30, 40 tons(as per need)

2. DC or AC driving for slitting and recoiling

3. Mitsubishi PLC controlling, VF speed control, touch screen operating

4. High speed design depends on material thickness

5. China famous brand products, specialized in the manufacturing slitting line and cut to length line

Work Flow

Material loading -- Uncoiling -- sheet feeding -- sheet head cutting -- center adjusting -- slitting -- tensioning and separating -- recoiling -- product unloading

Main Machine Components

Coil car.......................................................................................................1 set

Decoiler……...............................................................................................1 set

Feeding device..............……..……………...................................................1 set

Center adjusting device………………………..………………………………..1 set

Slittingng machine…..…………….………………………………………….…..1 set

Tensioning and pre-separater………..…………………………………………1 set

Recoiler.......................................................................................................1 set

Unloading coil car........................................................................................1 set

Hydraulic station………………..………………………………………………....1 set

Pneumatic system………………………………………………………………...1 set

Electric control system………….……….......................................................1 set

Main Electric Elements

Motor controller: Eurotherm/ Siemens/Mitsubishi

PLC: Mitsubishi/Siemens

Encoder: Omron

Inverter: Mitsubishi/Yaskawa/Delta

Touch screen: Inovance/Delta

Parameters:

1. Precision high speed slitting line:

| series | material thickness/mm | Material width | speed/mpm |

| 1 | 0.2-3 | 400-2000 | 0-250 |

2. Series of slitting lines:

| series | material thickness/mm | Material width | speed/mpm |

| 1 | 0.2-2 | 400-2000 | 0-50-150 |

| 2 | 0.3-3 | 400-2000 | 0-50-120 |

| 3 | 0.5-4 | 500-2500 | 0-50-120 |

| 4 | 0.8-6 | 500-2500 | 0-50-100 |

| 5 | 2.0-8 | 500-2500 | 0-50-80 |

| 6 | 2.0-10 | 500-2500 | 0-30-50 |

| 7 | 3.0-12 | 800-2500 | 0-30-50 |

| 8 | 3.0-14 | 800-2500 | 0-30-50 |

| 9 | 4.0-16 | 800-2500 | 0-30-50 |

| 10 | 5.0-20 | 800-2500 | 0-30 |

According to the line spec, FCL will be needed for the shipment.

Normally three or more 40 feet containers for shipment

- One stop service for customized machine

- Overseas installation & operating training

- One year warranty of the whole machine

- Life-long technical support

1. Machine installation & commissioning, training:

1-2 technicians will be dispatched to Buyer’s plant for installation & commissioning. Work period: in 5 days

The expense of round trip tickets, accommodation, safety and interpretation shall be covered by Buyer, additional pay allowance to the technicians.

2. warranty: one year

3. Price basis: FOB or CNF or CIF

4. We will provide the foundation drawing to Buyer in 20 days after receiving the down payment.

Foundation Reference