- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

31 kN

-

Theoretical Shot Volume(cm³):

-

154 cm³

-

Injection Rate (g/s):

-

144 g/s

-

Injection Weight (g):

-

144 g

-

Screw Speed (rpm):

-

1 - 180 rpm

-

Screw diameter (mm):

-

35 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

360*360mm

-

Weight (KG):

-

3100 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

320 mm

-

Brand Name:

-

WATON

-

Power (kW):

-

9 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Screw Diameter:

-

35mm

-

Injection Volume:

-

154g

-

Clamping force:

-

900Kn

-

space between tie bars:

-

360*360MmXmm

-

Oil tank capacity:

-

160L

-

Opening Stroke:

-

320mm

-

Power(W):

-

9kw

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

360mm

-

Distance between Tie Bars(Height)(mm):

-

360mm

-

Mold Height(mm):

-

150 - 360 mm

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

31 kN

-

Theoretical Shot Volume(cm³):

-

154 cm³

-

Injection Rate (g/s):

-

144 g/s

-

Injection Weight (g):

-

144 g

-

Screw Speed (rpm):

-

1 - 180 rpm

-

Screw diameter (mm):

-

35 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

360*360mm

-

Weight (KG):

-

3100 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

320 mm

-

Brand Name:

-

WATON

-

Power (kW):

-

9 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Screw Diameter:

-

35mm

-

Injection Volume:

-

154g

-

Clamping force:

-

900Kn

-

space between tie bars:

-

360*360MmXmm

-

Oil tank capacity:

-

160L

-

Opening Stroke:

-

320mm

-

Power(W):

-

9kw

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

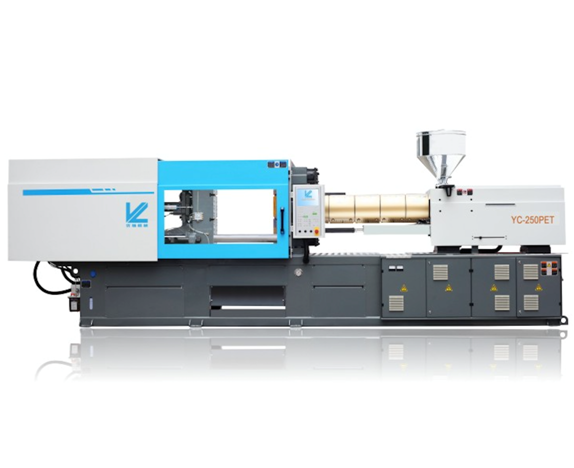

| Device | Item | Model | B | |

| Injection Device | Screw diameter | mm | 35 | |

| Screw L/D ratio | L/D | 20 | ||

| Theoretical shot volume | cm3 | 154 | ||

| Injection weigt | g | 144 | ||

| Injection pressure | Mpa | 179 | ||

| Screw speed range | r/min | 0~180 | ||

| Making-up Device | Clamping force | KN | 900 | |

| Clearance between tie bars | mm | 360×360 | ||

| Opening stroke | mm | 320 | ||

| Max.Mould height | mm | 360 | ||

| Min.Mould herght | mm | 150 | ||

| Ejector force | KN | 31 | ||

| Ejector stroke | mm | 100 | ||

| Other | Pump power | KW | 9 | |

| Heating power | KW | 6.5 | ||

| Oil tank capacity | L | 160 | ||

| Machine weight | t | 3.1 | ||

| Weight dimension | mmm | 4.2×1.1×1.7 | ||

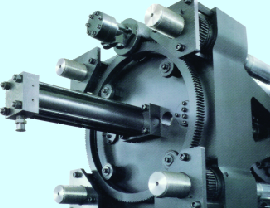

1 Clamping Unit

High rigidity mold platen with enlarged space between tie bar,fit for larger scope of the molds.

Triple secured protection in Mechnical,electrical,hydraulic Systems.

Mold platen with both T-slot & mold mounting holes for different molds installation.

Large moving die stroke with smooth & fast motion.

Four-stage control for pressure,speed,position to lock & open the platen.

Automatic centralized lubrication system.

Gear regulating the mold driven by oil motor.

Electric ruler for open/close mold & ejection.

Automatic adjustment structure.

Adujustable moving platen sliding feet.

2 Control Unit

excellent computer with rapid response,interactive interface.

Regulate barrel temperature deviation automatically.

Multiple-unit plastic molding data memory system.

Famous brand main electric components ensures safety performance of electric devices.

It real-timely monitors various actions & give automatic warning for its defects.

Clamp,injection,ejection action can choose linear Displacement sensor for its control.

Data protection lock for parameters.

Motor safety protection device.

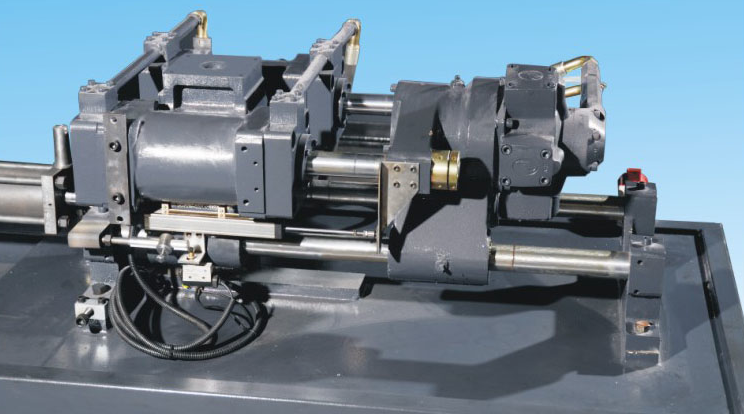

3 Injection Unit

Twin cylinder balanced injection system.

High torque oil motor directly drives screw to complete the pre-injection.

Specific screw & barrel designs are available for processing different material requirements to ensure the production quality.

Multiple-stage control for pressure,speed,position to inject,keep pressure,charge material.

Injection position detection control.

Anti-cold start (prevention) of screw.

3-Mode carriage retreat mode.

Anti flow backward device of screw.

Back pressure regulation.

Nozzle regulation device.

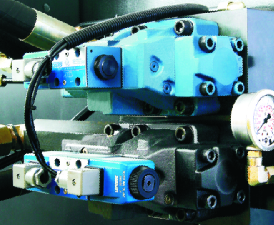

4 Hydraulic Unit

High capacity feedback proportional valve controlling the pressure & flow, stability & high sensitivity speed.

Main hydraulic components with famous brand,ensuring stable qulity of the machine.

Low noise & rapid response oil pump system.

Adopt the cooling water flow distributor,controlling the cooling temperature easily.

High-precision suction filter.

Alarm for oil temperature deviation function.

Oil level monitoring function.

1.How to send my enquiry?

You can contact us by email, phone call, Instant Messenger (Whats APP, We Chat, Skype).

2.How long can I get feedback after enquiry?

We will reply you within 10hrs in working day.

3.Where is your factory located? How can I visit there?

Our factory is located in Huang Yan, Tai Zhou City, Zhe Jiang Province, China. There has flight from Shanghai(one hour), Guang Zhou(2 hrs) and Shen Zhen(2 hrs) to our city. Train from Shanghai to our city is 4 hrs. Welcome to visit our factory.

4.Delivery time

Machines & molds order takes 30 days after pre-payment received. Preform orders depends on the qty. Please inquiry sales.

5.What is the package? Is it suitable for shipment?

Machines will be packed by standard wooden case. It is very much strong for oversea transportation. Preforms are packed by standard double layer carton.

6.Payment term

30% by T/T as down payment, balance 70% by T/T or L/C before delivery. We offer credit to customers, in which case the balance payment could be months after delivery. Welcome to inquiry sales.

7.Can I trust you?

Sure, we’re Alibaba verified supplier & Alibaba Trade Assurance Suppier.

8.How long is the warranty for machines?

Machines warranty is 12 months from installation & commissioning.

9.How' s your after-sale service?

Out after sales support and service is second to none and we urgently respond to your queries, if parts are required they would be sent to you by international courier within 48 hrs upon registering your need

10.Can you engineer come to our place to help with machine installation & commission?

Yes, our engineers are available to travel to your place. Round flight tickets & accommodation will be at your cost.

.