Raise the spiral chute and fix it in the proper position, sand pump transport the ore to the feed inlet, adding water to adjust the concentration of the slurry. The slurry naturally swirls from high to low, and generates an inertial centrifugal force in the rotating bevel flow rate. The mineral is separated from the sand by the gravity and centrifugal force of the swirl by the difference in specific gravity, grain size and shape of the ore. The concentrate flows into the concentrate bucket and is connected by the pipeline. The tail sand flows into the tailing sand bucket and is connected to the sand pool by the pipeline, and then drained by the sand pump to complete the whole process of the beneficiation.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customization

-

Dimension(L*W*H):

-

different type

-

Weight:

-

500 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Spiral Chute

-

Application:

-

Silica sand separation

-

Color:

-

As required

-

After sale service:

-

Online support,Field installation,Commissioning,training

-

After-sales Service Provided::

-

Video technical support, Free spare parts, Online support,

-

Certification:

-

ISO

-

Local Service Location:

-

Afica

-

Installation:

-

Technical Guidance

-

Application area:

-

Gravity Separator Machine

-

Factory Visit:

-

Welcomed Warmly

Quick Details

-

Production Capacity:

-

99%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongji

-

Voltage:

-

Customization

-

Dimension(L*W*H):

-

different type

-

Weight:

-

500 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Spiral Chute

-

Application:

-

Silica sand separation

-

Color:

-

As required

-

After sale service:

-

Online support,Field installation,Commissioning,training

-

After-sales Service Provided::

-

Video technical support, Free spare parts, Online support,

-

Certification:

-

ISO

-

Local Service Location:

-

Afica

-

Installation:

-

Technical Guidance

-

Application area:

-

Gravity Separator Machine

-

Factory Visit:

-

Welcomed Warmly

Product Description

High quality sea sand concentrate machine spiral chute

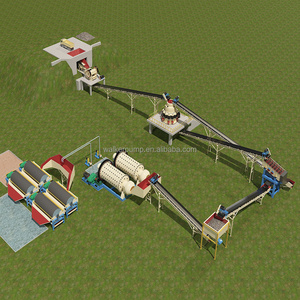

Our factory produce full sets mining equipments for quartz rock chromite ore processing, separation. The equipments including feeder machine, jaw crusher, cone crusher, ball mill, spiral classifier, shaking table, jigger machine, spiral separator, magnetic separator...

Spiral Chute is the best equipment for mining and mineral processing, which combines the characteristics of the spiral concentrator, shaking table and Centrifugal concentrator. It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover, light moisture proof, anti-rust. It is mainly used for separation and recovery of a wide range of minerals: zircon, ilmenite, rutile, iron ore, chromite, manganese, tin, tantalum and tungsten ore, silica sands, gold, copper and base metals and etc., as well as other non-ferrous metals, rare metals and non-metallic minerals.

Features

1.Reasonable structure and small occupation area.

2. High recovery, high efficiency, and precise separation.

3. Light in weight, rust and corrosion resistant.

4. Simple installation and Minimal maintenance requirements.

5. Low operating cost and long operating life.

6. Reliable running with minimal operator attention.

7. Strong adaptability to fluctuation of feeding amount, density, size and grade.

Structure

Working principle

Specification

Our Successful Case

It is applicable for separation of granularity ranged from 4mm to 0.02mm metallic minerals such as iron, ilmenite, chromite, tungsten-tin ore, niobium-tantalum ore, gold placer, seashore monazite, rutile and zircon as well as other metallic and non-metallic minerals with adequate difference of specific gravity. For the seaside, riverside, sand beach, the stream of placer mining, it is the best equipment of all.

Packing & Delivery

Packing

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below:

1. Nude packing.

2. Bundle packing.

3. Grass rope packing.

4. Water proof packing.

5. Wooden pallets packing.

6.Wooden box or carton box packing.

Delivery

Usually the equipments are delivered aboard by tracks,trains,or container(sea transportation). and some spare parts or very small goods also support to send by express, our company have built good relationships with large cargo agent and shipping companies which guarantee our products delivered safely and promptly.Sea transportation includes three delivery ways as below:

1.

40HQ container

: used for goods without over length, over height and overweight;

2.

FR(Flat Rack) container

:suitable for large equipments with over length, over height like ball mill,excavator,etc.

3.

Bulk cargo shipment (LCL)

: used for some goods without loading in full container,normally it requires good packing with marks for safety and easy to be trackable.

Hot Searches