- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380V, 220V, 240V

-

Weight (KG):

-

1000 kg

-

Raw material:

-

sand, gypsum, lime, cement, flyash, etc

-

Product Name:

-

aac block making machine

-

capacity:

-

10,000~6,000,000m3/ year

-

Application:

-

Buliding Construction

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Type:

-

Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Clay, cement, gypsum, sand, lime, etc

-

Production Capacity (Pieces/8 hours):

-

Other

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380V, 220V, 240V

-

Weight (KG):

-

1000 kg

-

Raw material:

-

sand, gypsum, lime, cement, flyash, etc

-

Product Name:

-

aac block making machine

-

capacity:

-

10,000~6,000,000m3/ year

-

Application:

-

Buliding Construction

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Field installation, commissioning and training

aac block machine price aac blocks production line manufacturer building blocks making machine

Product Description

AAC block manufacturing machine

Aerated concrete block equipment (gas filling block equipment) is a new type of building materials machinery equipment. Our company has combined domestic and foreign aerated concrete technology to save resources and protect the environment development.

and we can supply complete set of autoclaved aerated concrete plant with 10 000m3, 2

0 000m3,

50 000m3, 100 000m3, 150 000m3, 200 000m3, 250 000m3, 300 000m3 capacity annually, including plant design, equipments installation, technical instruction, personal training, etc, and also can design and manufacture as per clients' requirement.

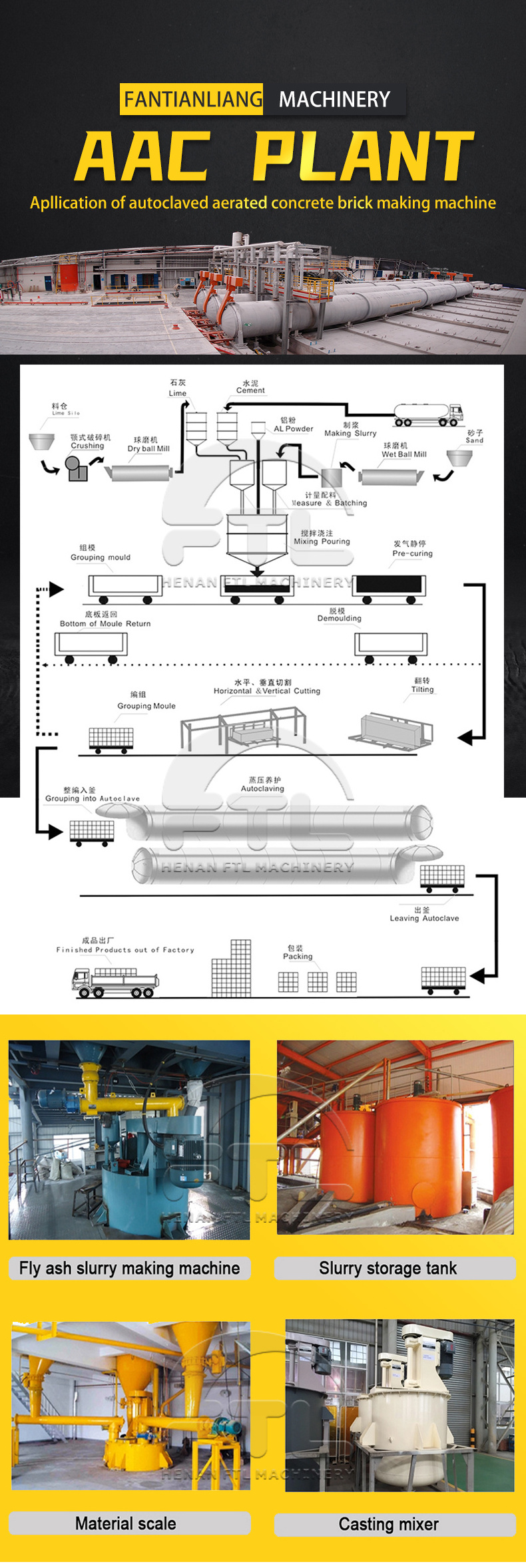

Introduction of AAC Block Production Line

1.Storing and supplying of raw materials of AAC blocks:

All raw materials are carried into factory by trucks, such as Fly ash, sand or lime are gathered in specified raw materials field waiting for use. Sacks of cement and bulk cements stored in cement warehouse.

2.Processing of raw materials:

Fly ash, sand or limestone is sent into ball mills by vibration feeders and belt conveyor.Then fine powders of flyash,sand or lime are pumped into slurry tank.

3.Aerated block ingredients,stiring and casting:

Flyash (or sand or stone powder )and waste slurrry are measured in measuring tank.After the measuring and mould in their place,slurry stirring begins. Slurry temperature should reach about 40°c.

Raw material processing

4. Aerated block’s precuring and cutting

Ingredients pouring

Cutting Section.

After pouring and foaming, the green body is statically stopped to a certain hardness

Autoclave

After cutting the green bodies, they can be marshalled to a certain number by driving and then enter the autoclave for autoclaving.

The normal production capacity:

| Annual Capacity ( 300days ) | Power | Daily Capacity | Cycle Time | No. of Autoclaves |

plant area (m2) |

| 50,000m ³ /year | 400KW | 166 m ³ /day | 8 hours | 2 | 2000 |

| 100,000m ³ /year | 500KW | 333m ³ /day | 8 hours | 4 | 2000 |

| 150,000m ³ /year | 630KW | 500m ³ /day | 8 hours | 6 | 2500 |

| 200,000m ³ /year | 720KW | 666m ³ /day | 8 hours | 8 | 3000 |

| 300,000m ³ /year | 1186KW | 1000m ³ /day | 8 hours | 6(D2.85*32.5) | 3500 |

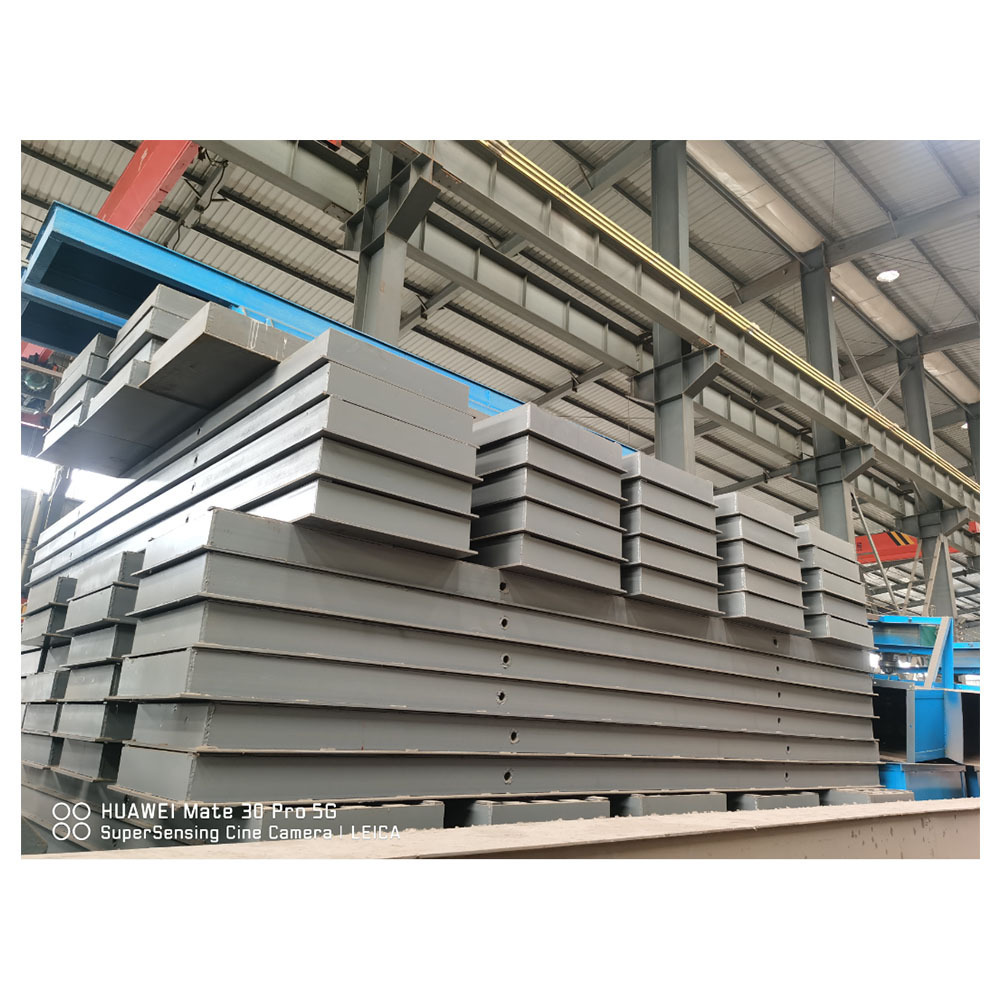

Main equipment

Jaw crusher

It is mainly used for medium and coarse crushing of materials with compressive strength not exceeding 320 MPa. It has the characteristics of large crushing ratio, high output, uniform product size, simple structure, reliable operation, simple maintenance and economical operation. The crusher has been widely used in mining, smelting, building materials, roads, railways,

water conservancy and other departments.

water conservancy and other departments.

Ball mill

It is suitable for grinding various ores and other materials. It is used in mineral processing, building materials and chemical

industries. It can be divided into dry and wet grinding methods. Depending on the method of discharge, it can be divided into two

types: grid type and overflow type

industries. It can be divided into dry and wet grinding methods. Depending on the method of discharge, it can be divided into two

types: grid type and overflow type

Pouring mixer

It is a material mixing machine before the pouring of the steamed and aerated concrete body, which is located above the mold. It is used for stirring slurry, cement, quicklime, gypsum and aluminum powder paste suspension which are injected into the tank

according to a certain ratio, uniformly mixing, fully reacting, and timely injecting the mixed slurry into the mold

according to a certain ratio, uniformly mixing, fully reacting, and timely injecting the mixed slurry into the mold

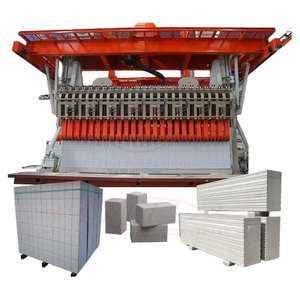

Cutting machine

the AAC block is formed after casting and precuring, as the size is too large, it must be cut to achieve the required product

size.

Cutting process

Using reversal crane carry the mould and block to demould on cutting cart. The cutting cart will take the block to level cutting

machine

size.

Cutting process

Using reversal crane carry the mould and block to demould on cutting cart. The cutting cart will take the block to level cutting

machine

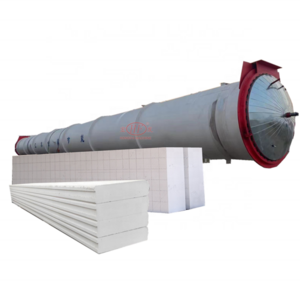

Autoclave

Finished cutting using semi-product crane carry to the front of autoclave grouped, hoisting machine or dragger will drag steam

trolley into autoclave to steam, it need 8-12 hours.

trolley into autoclave to steam, it need 8-12 hours.

Final packing

Using finished block carry hanger clamp the finished product to package line on wooden pallets, after package, then by forklift transport the finished products to piled yard according to specifications to stack.

Automatic control system

Automatic control system adopts famous brand and

supports

Packaging & Shipping

Hot Searches