Model Selection Table

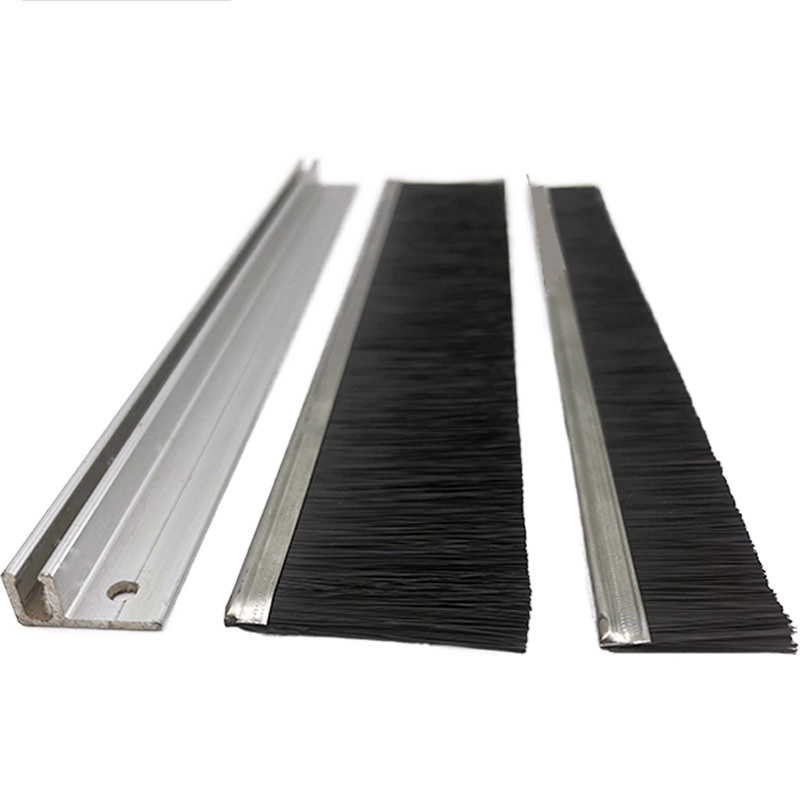

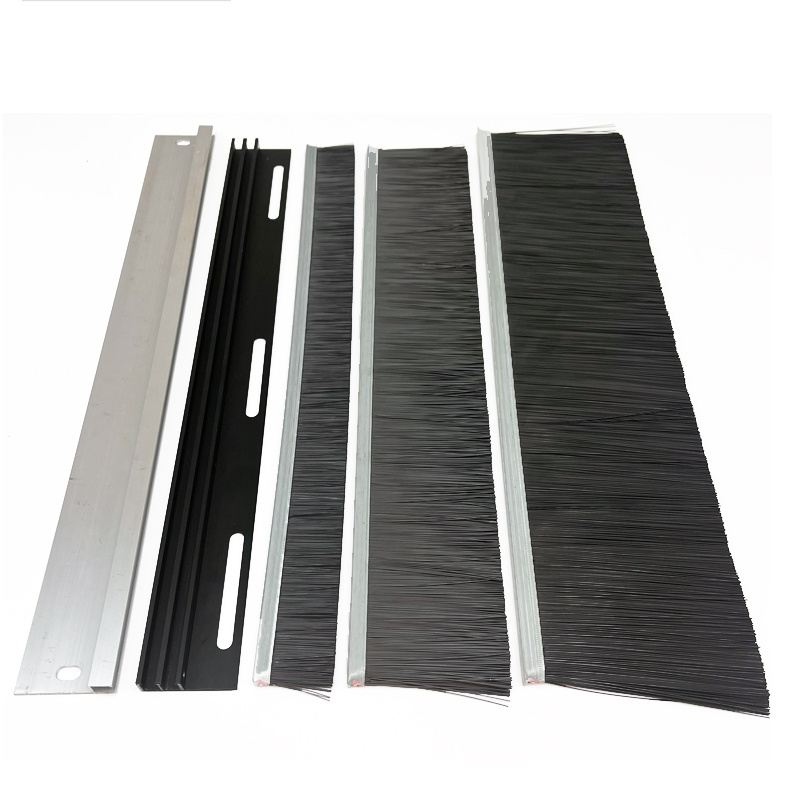

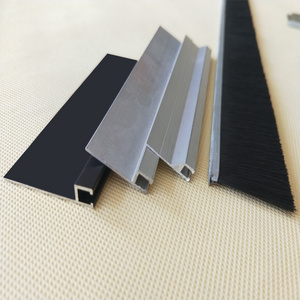

Note 1: If the iron brush is inserted into a slot for use (aluminum slot or plastic slot),

it is better to provide a sample of the slot to ensure that the produced brush can be

inserted into and suitable for this slot.

Eg: D A-5-5-40-398-03 A B S

①②③④ ⑤ ⑥ ⑦ ⑧⑨⑩

Description and Selection:

① Design No

D

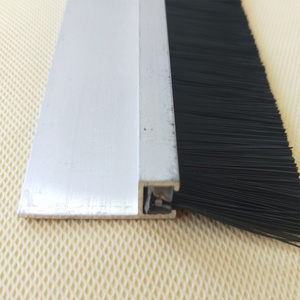

D: Iron backing strip brush

② : Brush backing material

A: Electrolytic galvanized plate B: 304 stainless steel

③ : Bottom width of brush backing

Note: Please fill in the bottom width of the brush backing as required (as shown in ③ above figure, the most commonly used ones are 3, 3.5, 4, 4.5, 5, 6, 8, 9, 10, 11, 12mm)

④ : Side height of brush backing

Note: Please fill in the side height of the brush handle as required (as shown in ④ in the above figure, the most commonly used is 3, 4, 5, 6, 8, 9, 10, 11,12mm, generally 1mm wider than the bottom of the brush backing, or the same width as the bottom of the brush backing)

⑤ : Total height of brush

Note: Please fill in the total height of the brush as required (as shown in ⑤ in the above figure, 5-200mm is commonly used)

⑥ : Total brush length

Note: Please fill in the total length of the brush as required (as shown in ⑥ in the above figure, 20-3000mm is commonly used)

⑦ : Bristles diameter

015:0.15mm 020:0.2mm 025:0.25mm 030:0.3mm 040:0.4mm 050:0.5mm 060:0.6mm

⑧ : Brush material and performance

A: Common nylon PA6 (low cost, high recovery)

B: UL94-V0 flame retardant PA (nylon) (high recovery, high flame retardant)

C: Anti static nylon PA6 (high recovery,

resistance value:

1E10-1E12Ω,1E8-1E10Ω

)

D: common PBT (low cost, high recovery, high hardness)

E: UL94-V0 flame-retardant PBT (high recovery, high flame retardancy and high hardness)

F: Common PP (low cost, high hardness)

G: UL94-V2 flame retardant PP wire brush (low cost, high flame retardancy, high hardness)

H: Brass wire

J: stainless steel wire

K: animal hair

L: plant fiber

M: abrasive wire

N:electric conduction PA6(nylon6,

resistance value:

1E3-1E5Ω

)

O:High temperature resistant PA66 bristles(170℃)

P:Low temperature resistant PA66 bristles(-40℃)

Q:High temperature resistant PEEK bristles(220℃)

R:Food grade PP

S:Corrosion resistant PPS

T:Corrosion resistant PVDF

U:Common nylon66 PA66 (high recovery)

V:UL94-V0 flame retardant PA66 (nylon66) (high recovery, high flame retardant)

W:Common PET(low cost,high hardness)

X:Food grade PA610

Y:Food grade PA612

(PA6 nylon , PP ,and PBT bristles are commonly used)

⑨Brush color

B: Black BL: blue W: white R: red Y: yellow G: green O: orange P: purple T: transparent GR: gray

⑩ : Bristle shape

S: Straight wire W: corrugated wire (straight wire is commonly used)