- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Lianding

-

Application:

-

Plastic Recycling

-

Production Capacity (kg/h):

-

300 - 2000

-

Voltage:

-

380v 50hz 3phase

-

Dimension(L*W*H):

-

60M*3.5M*4.5M

-

Power (kW):

-

150-500kw

-

Weight (T):

-

30

-

Keywords:

-

Plastic PET Bottle Recycling Machine Line

-

Equipment material:

-

stainless steel

-

Manufacturer:

-

Lianding

-

Raw material:

-

PET Waste Plastic Bottle/Flake

-

Final product:

-

Clean PET Flakes

-

Contactor:

-

Schneider

-

Motor:

-

SIEMENS Motor

-

Function:

-

Crushing Washing Drying

-

Final Flakes Size:

-

8-14mm

-

Final moisture:

-

1-2%

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

2000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Lianding

-

Application:

-

Plastic Recycling

-

Production Capacity (kg/h):

-

300 - 2000

-

Voltage:

-

380v 50hz 3phase

-

Dimension(L*W*H):

-

60M*3.5M*4.5M

-

Power (kW):

-

150-500kw

-

Weight (T):

-

30

-

Keywords:

-

Plastic PET Bottle Recycling Machine Line

-

Equipment material:

-

stainless steel

-

Manufacturer:

-

Lianding

-

Raw material:

-

PET Waste Plastic Bottle/Flake

-

Final product:

-

Clean PET Flakes

-

Contactor:

-

Schneider

-

Motor:

-

SIEMENS Motor

-

Function:

-

Crushing Washing Drying

-

Final Flakes Size:

-

8-14mm

-

Final moisture:

-

1-2%

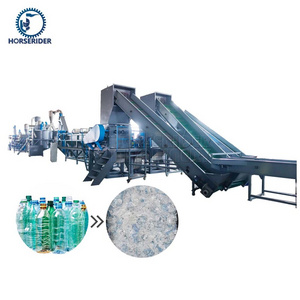

Waste Plastic PET Bottle Recycling Plant Machine Line Plastic Bottle Recycling Machine Price

Features

1. Automatically working, conveying material, crushing, washing, drying, collecting.

2. Finished product size: <16mm(customizable)

3. Moisture content: <3%.

4. High efficiency, safety control, large capacity.

Process flow:

Belt conveyer → Metal separator →Sorting platform → Belt conveyer → Label Separator→ Crusher → Screw loader → washing tank → Friction washing machine → Screw loader→ Hot Washer→ Screw loader → Dewatering machine→ Washing tank 2 → Dewatering machine →Pipe b lower dryer system →Zigzag label separator → Storage silo → Finished product packing

Specifications of machine:

| Input capacity | 500kg/h | 1000kg/h | 2000kg/h |

| Workshop(M*M*M) | 40 (L)×10(W)×6(H) | 55(L)×15(W)×6(H) | 70(L)×18(W)×6(H) |

| Ancillary staff | 4Persons | 6Persons | 8Persons |

| Installation power | 156kw | 307kw | 420kw |

| Water Consumption | 2Ton/h | 3Ton/h | 4Ton/h |

| Final product | Moisture: max 3% | Moisture: max 3% | Moisture: max 3% |

Photos show:

Crusher : can crushing with water, cut plastic pet bottles into small pieces.

Washing tank: separate the sand, soil and other dirties

Hot washer: with hot & chemical water washing to remove glue and greasy dirt from flakes

Vertical dewatering machine: remove water from pet flakes, making flakes dry.

More pictures of machine:

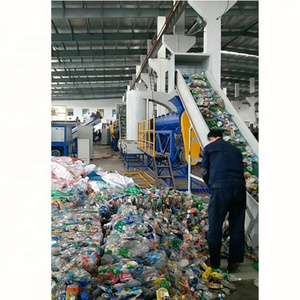

Feedback of our clients: