- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

Porcelain processing factory

-

Product name:

-

Ceramic roller press

-

Application:

-

Ceramic Tableware

-

Function:

-

Multifunctional

-

Name:

-

Ceramic roller press

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

220~380

-

Keyword:

-

Ceramic roller press

-

Model:

-

JR-200

-

Type:

-

Autamtic Working

-

Feature:

-

High Efficiency

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JR-200

-

Weight (KG):

-

2200

-

Applicable Industries:

-

Porcelain processing factory

-

Product name:

-

Ceramic roller press

-

Application:

-

Ceramic Tableware

-

Function:

-

Multifunctional

-

Name:

-

Ceramic roller press

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

220~380

-

Keyword:

-

Ceramic roller press

-

Model:

-

JR-200

-

Type:

-

Autamtic Working

-

Feature:

-

High Efficiency

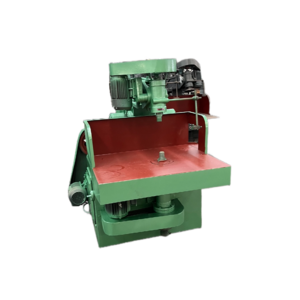

Products Description

Ceramic product molding and production machine

JR series ceramic rolling forming machine.

The rolling molding tool is a silicone roller head, which is a rotating body, and the bus bar of the rotating body of the rolling head is the same as the bus bar of the forming surface of the billet. When forming, the roller head mainly has relative rolling in addition to relative sliding for the mud. Rolling molding is widely used because of its good quality and simple operation. Rolling molding equipment is rolling molding machine, due to the wide variety of ceramic products, shapes and sizes are different, so with the different products, rolling molding has different structural forms, to the 10-inch disc single-head molding machine as the design object.

1.2 Ceramic technology and Market conditions Ceramic technology for the prepared blank, through a certain method or means, the billet deformation, into a certain shape of the body, forming the blank fineness, water content, plasticity, fluidity, etc., molding performance requirements, the line should meet the green dry strength, density of the body. The raw body is still a semi-finished product after forming, which needs to be dried, glazed and assembled, and operated by multiple processes. Therefore, high enough green strength can reduce the damage of green as much as possible, which is of great significance for improving the efficiency of forming production.

Therefore, the green billet should meet: (1) The shape and size of the green billet that meet the requirements of the drawings and product samples. (2) The forming blank has the mechanical strength required by the process to adapt to the subsequent operation. (3) The body structure is uniform and has a certain density.

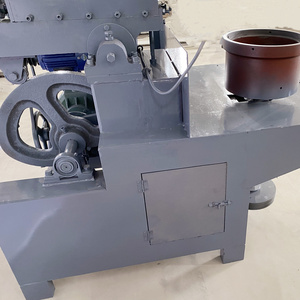

The machines are divided into different models and can produce different maximum sizes

Roll forming:

When forming, the rolling head and the model of holding mud are rotated in the same direction about their own axis and are close to each other. The method by which the mud is stretched along the working face of the model under the action of rolling compaction.

1. The forming body has high density, high strength and is not easy to deform.

2, uniform body specifications, high production efficiency, reduce labor intensity.

3, do not need high operation technology, easy to form semi-automatic production line.

Main control of the machine: roller head up/forward/down/backward/upper mold switch/lower mold switch/machine

working mode (single or continuous)

Product Paramenters

|

Machine model

|

JR-200

|

|

Voltage

|

110/220/380. Customizable single-phase or 3-phase

|

|

Material

|

Thickened 304 stainless steel&carbon steel

|

|

Applicable to

|

Ceramic mugs/plates/flower pots/wine jars/irregular porcelain, etc

|

|

Size&Weight

|

1660*1360*2500mm 2T

|

|

Output

|

3-4pcs/H

|

Details Images

Hot Searches