Brief introduction:

1. The blending tank equipment adopts single-direction or double-direction wall scraping blending and frequency conversion speed

adjustment to satisfy different technological requirements.

2. Materials can be heated or cooled according to technological requirements. The heating methods such as steam or electric heating can be selected according to customer requirements.

3. Various forms of blending vanes are suitable for production of different types of products.

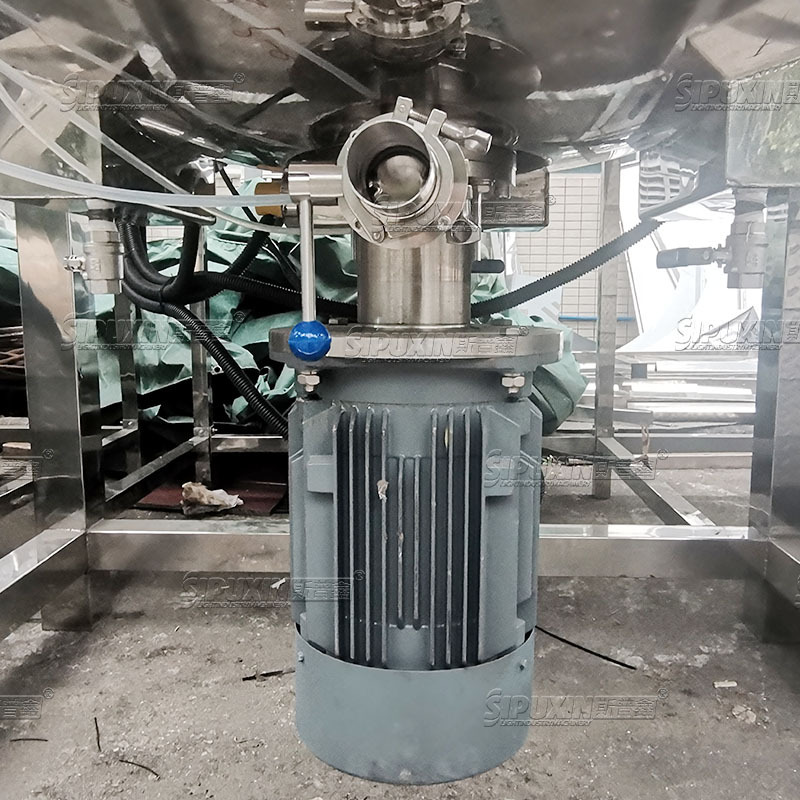

4. Made of imported SUS304 or SUS316L stainless steel. The mixing tank body and pipe are subjected to mirror polishing.

5. Bottom installation type disperse and pipeline type emulsifier are optional to speed up dissolution and emulsification of materials.

6. The stainless steel electric control cabinet can completely supervise the operation of equipment, and display such data as temperature and blending rotation speed etc.

Advantage:

1. High speed disperse can powerfully mix and disperse viscous solid and liquid materials, and rapidly dissolve many indissoluble liquid washing products, and thus, saving energy consumption and shortening production period.

2. The main blending adopts stepless speed variation device, which can reduce the formation of bubbles when the temperature is low and the viscosity is high. 3. The gear pump circulating discharging device can accelerate the forming of products and realize rapid discharging.