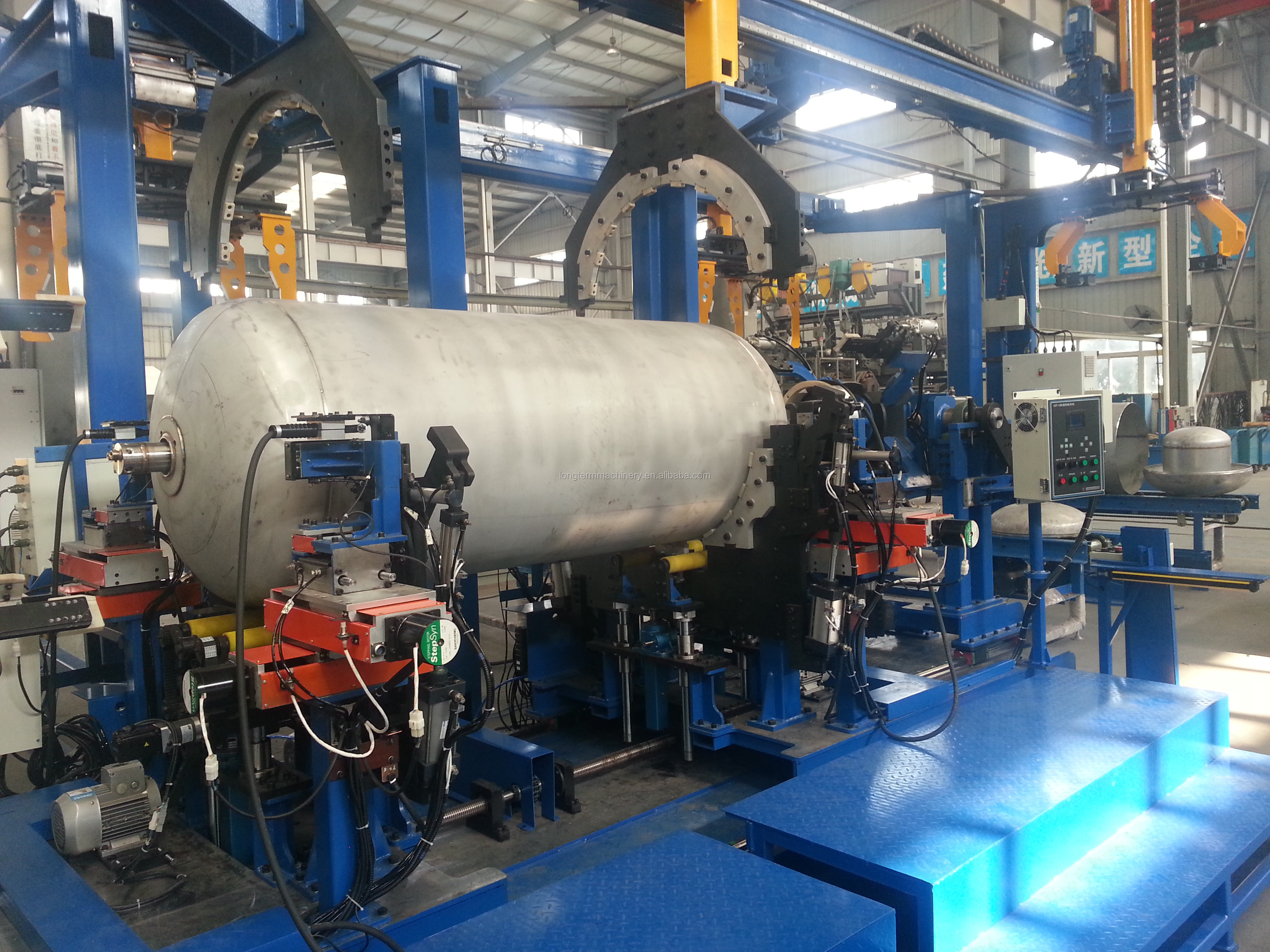

Automatic welding production line for rear Dome attachment

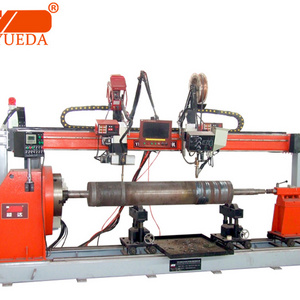

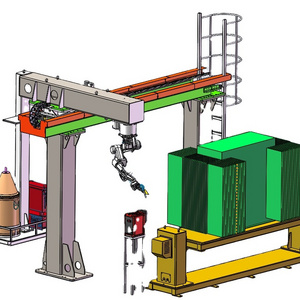

Features: Adopt a reasonable and advanced process layout process, a complete solution for the entire line, automation, and fewer people. Advantages: Automatic welding special machine, handling robot, welding robot are reasonably matched, and cooperate with automatic logistics transmission line to complete automatic logistics transmission and automatic welding of workpieces. The rear head adopts the accompanying tooling plate for positioning and transportation, and the accessories are automatically screened or manually fed. All welding procedures do not require manual participation in welding. It can complete the automatic welding of accessories such as support rods, reinforcing rings, small caps, reserved cylinders and other accessories.