- Product Details

- {{item.text}}

Quick Details

-

Working speed:

-

2m/mm

-

Supply voltage:

-

Three phase four wire,380V/50Hz

-

Certification::

-

PCB etching machine

-

Height:

-

1100mm

-

Control cabinet:

-

Touch screen and PLC

-

Transfer Direction:

-

Left to right

Quick Details

-

Place of Origin:

-

Beijing, China

-

Product name:

-

PCB machine

-

Transfer speed:

-

0.6~5Meter/minute(Adjustable)

-

Working speed:

-

2m/mm

-

Supply voltage:

-

Three phase four wire,380V/50Hz

-

Certification::

-

PCB etching machine

-

Height:

-

1100mm

-

Control cabinet:

-

Touch screen and PLC

-

Transfer Direction:

-

Left to right

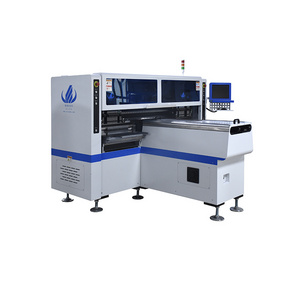

Full Automatic chemical metal PCB manufacturing machine

PCB machine

1. Process

Load Þ develop ing Þ fresh chemical rinse Þ flush sewage Þ pressure rinse 1,2,3,4 Þ fresh water rinse Þ inspection Þ Etching Þ fresh chemical rinse Þ pressure rinse 5,6 Þ fresh water rinse Þ inspection Þ Stripping Þ flush sewage Þ pressure rinse 7 Þ acid rinse Þ pressure rinse 8,9 Þ fresh water rinse Þ drying Þ unload

2.Basic Specifications

|

1) |

Dimensions: |

19126mm (L) X 2682mm (W) X 2500±25mm (H) |

|

|

2) |

Workpiece size: |

i) 610 X 610mm |

[maximum] |

|

|

|

ii) 200 X 200 mm |

[minimum] |

|

|

|

iii) 0.075 (No copper)~2.5 mm |

[thickness] |

|

3) |

Transfer speed: |

0.6~5Meter/minute(Adjustable) |

[preset speed: 1.5Meter/minute] |

|

4) |

Conveyor height: |

1100±25mm |

|

|

5) |

Conveyor width |

700mm |

[work width: 610mm] |

|

6) |

Wheel diameter: |

Æ32mm |

|

|

7) |

Wheel base: |

25mm |

|

|

8) |

Power supply: |

3phase 380V AC 50Hz 83 KW |

|

|

9) |

power consumption: |

<40Kw.h/When (board power consumption per square meter to do:0.80 / m²) |

|

|

10) |

Water Consumption: |

18~36 L / min (11.0L / m²) |

[fresh water] |

|

11) |

Exhaust: |

12.6 m3 / min |

[Non-dry section] |

|

|

|

8.4 m3 / min |

[Dry section] |

|

12) |

Control cabinet: |

Touch screen and PLC |

|

|

13) |

Transfer Direction: |

Left to right |

[Viewed from front] |

|

14) |

Number of drainage | 3 for chemical 1 for sewage, total 4 | |

|

15) |

Drain direction |

load or unload |

|

|

16) |

note |

if no plate, machine will be stop, power saving function |

3.Chemical reaction time:( To work speed 1.5m / min)

|

Development: 52S |

(Effective length: 1293mm,Operating temperature: 30℃) |

|||

|

Etching: 90S |

(Effective length: 2250mm,Operating temperature: 50℃) |

|||

|

Stripping: 80S |

(Effective length: 2050mm,Operating temperature: 50℃) |

|||

4.Capacity calculation:( To work speed1.5m / min)

|

1) Workpiece size: |

18 "× 24" (460 × 610) |

|

|

|

2) put plate distance: |

The distance between each of the circuit board 50mm |

||

|

3)Speed of work: |

1.5m / min |

|

|

|

4) Capacity (pieces/hour) |

1500 ÷(460 + 50)mm × 60minute |

approximately176PCs/hour |

|

|

5) Capacity (pieces/day) |

176 × 20hour |

approximately 3520PCs/day |

|

|

6) Capacity (pieces/month) |

3520 × 26day |

approximately 91520Item/month |

|

|

7) Capacity (sq. Ft./month) |

94520 × 3Sq.ft× 80% |

About219 648Sq.ft/month |

|