- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

FANUC

-

Cutting Area:

-

2030mm*4050mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

DSP

-

Place of Origin:

-

Shandong, China (Mainland)

-

Brand Name:

-

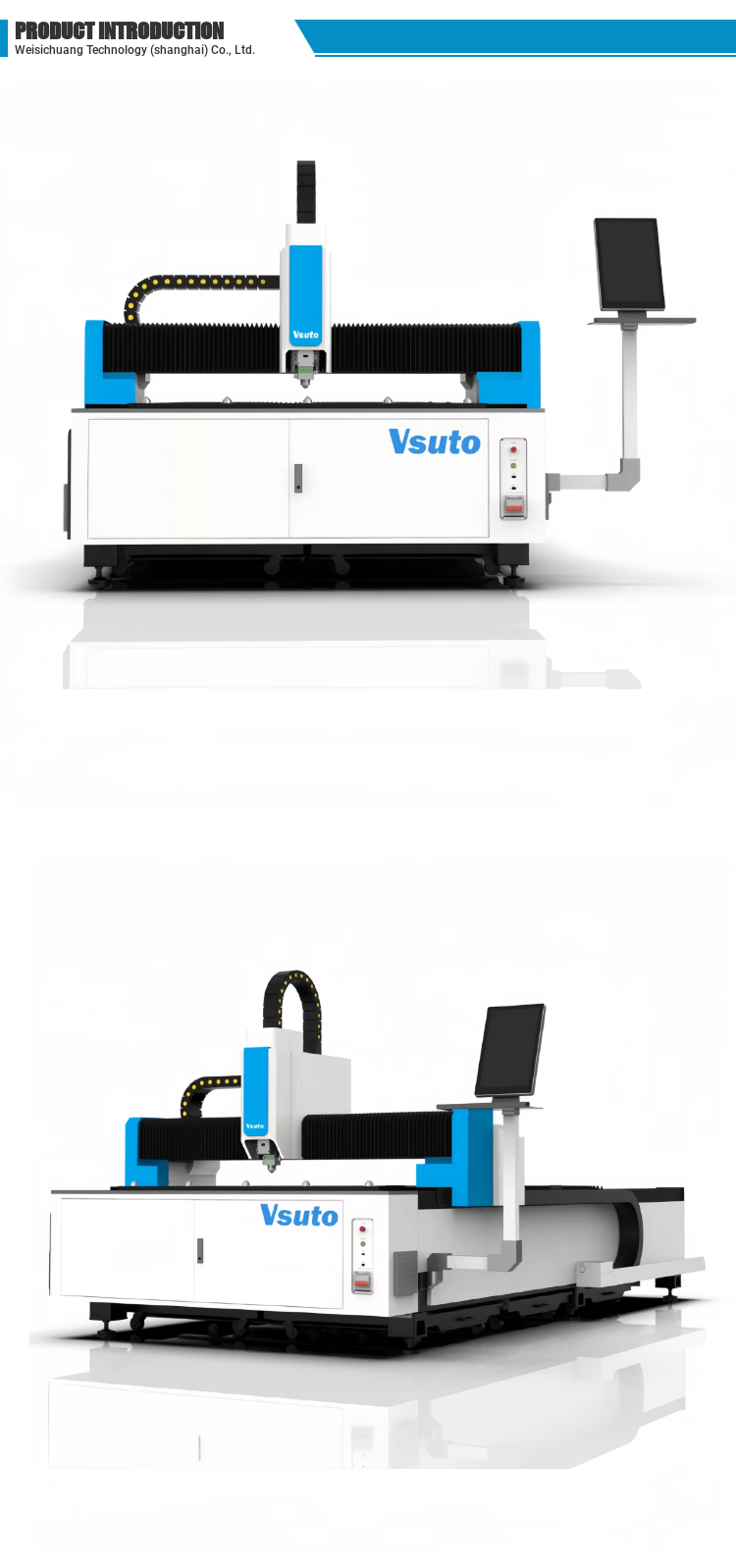

vsuto

-

Weight (KG):

-

1200 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

3000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

FANUC

-

Cutting Area:

-

2030mm*4050mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

DSP

-

Place of Origin:

-

Shandong, China (Mainland)

-

Brand Name:

-

vsuto

-

Weight (KG):

-

1200 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

| laser power | 1000W/1500W/2000W/3000W/6000W |

| Cutting stroke | 3050*1530mm |

| Cutting thickness | 3mm |

| Laser wavelength | 1080nm |

| Adjustment frequency | 5000HZ |

| Fiber length | 15m |

| Positioning accuracy | ±0.05mm |

| Repeatability | ±0.03mm |

| Maximum cutting speed | 100m/min |

| Maximum acceleration | 1.5G |

| 3 axis linkage speed | 115mm/min |

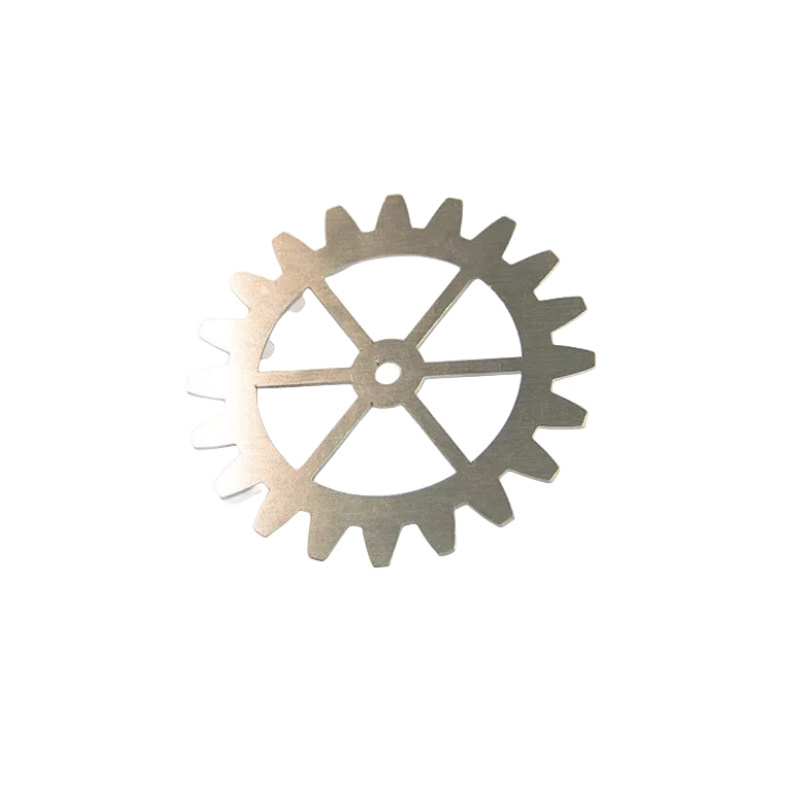

| Processing metal | carbon steel ,stainless,aluminum alloy,abrass |

| Processing format | 3050mm*1530mm,4050mm*1530mm,6050mm*1530mm |

ABOUT US

Vsuto technology Co.,Ltd. is a research and development, production and sales of laser equipment as one of the independent laser brand.The company has been adhering to the "'customer first, excellence" concept, to serve every enterprise every customer. We are the laser industry applidi experts, is your trusted partner, the future we will live up to expectations, as always to provide you with better products and services

With professioal laser exprience and good technical team.the company produces all kinds of laser equipment to meet customer needs. Has formed including laser marking, laser inkjet, laser cutting, laser welding, laser cleaning, laser hardening and other processes including a complete laser processing equipment production line, to provide customers with laser non-standard customized equipment and a set of laser processing solutions, so that laser technology and the manufacturing process of various industries seamless docking