- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YIHUI

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

2250*1910*4000mm

-

Weight (T):

-

16 T

-

Model Number:

-

YHA3

-

Motor Power (kw):

-

31 kw

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Power Source:

-

Hydraulic

-

Speed:

-

Adjustable

-

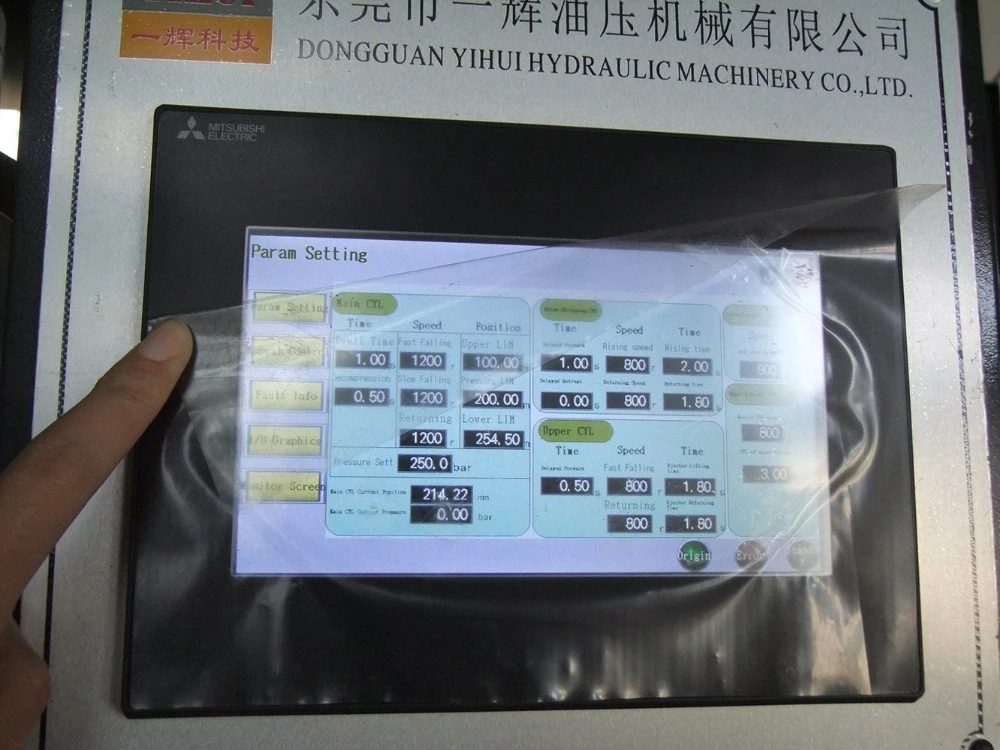

Parameter set saving:

-

20 groups

-

Precision:

-

0.02mm

-

Save energy:

-

60%

-

Mould:

-

provide

-

process technology:

-

provide

-

compelete solution:

-

provide

-

Customer local language:

-

show on touch screen

Quick Details

-

Machine Type:

-

Hot Forging Hydraulic Press

-

Return Force (kN):

-

8000 kN

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YIHUI

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

2250*1910*4000mm

-

Weight (T):

-

16 T

-

Model Number:

-

YHA3

-

Motor Power (kw):

-

31 kw

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Power Source:

-

Hydraulic

-

Speed:

-

Adjustable

-

Parameter set saving:

-

20 groups

-

Precision:

-

0.02mm

-

Save energy:

-

60%

-

Mould:

-

provide

-

process technology:

-

provide

-

compelete solution:

-

provide

-

Customer local language:

-

show on touch screen

The newest /CE Certification/ 800 Ton hydraulic press/H Frame type gantry forging press

Why so many famous brand company cooperate with us ?

1.Our factory have specialized in independent development and producing hydraulic press for 19 years.

So the product is stable and high quality.

2. Machine body, we use bending structure , much stronger than the common welding structure .

3. Oil pipe, we use Clip-on structure , much tight than common welding structure. Prevent oil leakage.

4. We take integrated oil manifold block, much easier to check machine and repair machine.

5.The main components are imported from Germany, Italy and Japan . So the quality is near the Japan production, but the unit price is lower than Japan production.

6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.

Work piece Samples

Work piece Samples

100Ton Hydraulic Press Cnc Machining Stainless Steel Balls Flat Forging Machine Shaft

steel balls forging machine

cnc machining stainless steel forging shaft

flat forging machine

1) Fine blanking metal parts

2) Cold extrusion molding and stamping for LED radiator, auto spare parts, cellphone casing and hardware tools, etc.

3) Molding and stamping for metallic and non-metallic.

YIHUI Hydraulic press with servo system, can bring you 10 kinds Advantages as below:

1.

Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.

English and customer country local language, bilingual operation interface, easy to operate.

3.

Can save 50% - 70% energy.

4.

Parameters and Speed can be adjusted on the touch screen, easy to operate.(Machine without servo system, speed can not been adjusted.)

5.

Can be 3 to 5 years longer service life than the common machine.

it means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.

Ensure safety and easy to know error,easy to do after service. Because of Automatic alarm and auto troubleshooting system.

7.

Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.

Very quiet , do not have noise.

9.

Much stable than common machine.

10.

Much high precision than common machine.

Dongguan Yihui Hydraulic Machinery Co., Ltd, is experienced in designing and manufacturing various types of hydraulic press machines and stamping machines,especially specialized in

manufacturing servo hydraulic press machine, cold Forging press machine, hot forging press machine, powder compacting press machine, heat hot hydraulic press machine, stamping hydraulic press.

The plant is established in 1999 ,covers an area of 5,000 square meters.

We are strictly implement the

ISO9001 , CE, and SGS

management standards.

YIHUI brand presses have been exported to

over 40 countries, such as Germany, USA, UK, Sweden, Japan, Slovenia, Saudi Arabia, Oman,

Russia, Serbia, Georgia, France, Finland,

El Salvador, Togo, Malaysia, Singapore, Australia ,

Thailand,

Vietnam, Pakistan, South Africa,

and so on.Hydraulic press machine mainly applied to hardware, automotive, die casting, electronic, cookware, paper and other industries.

We can provide total solutions, including machines, molds, product processing technology, automated production lines .

Options:

Digital Control, Common Control;

Slow Speed, Medium Speed, Fast Speed;

Water Cooler, Air Cooler, Forced Chiller;

Die Change/Die Clamp Device;

Interval Lubrication, Cycle Lubrication;

Upper Ejector, Bottom Ejector;

Right/Left Mould Opening Cylinders;

Die Change Trolley, Lower Moving Bolster;

With Mould Core-pulling & Ejecting Oil Circuit;

Mould Heating & Cooling System.

Overseas Exhibitions

Overseas Customers

Customers brand show