- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

300 Series

-

Surface Finish:

-

2B

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

RATO

-

Model Number:

-

AISI 304

-

Application:

-

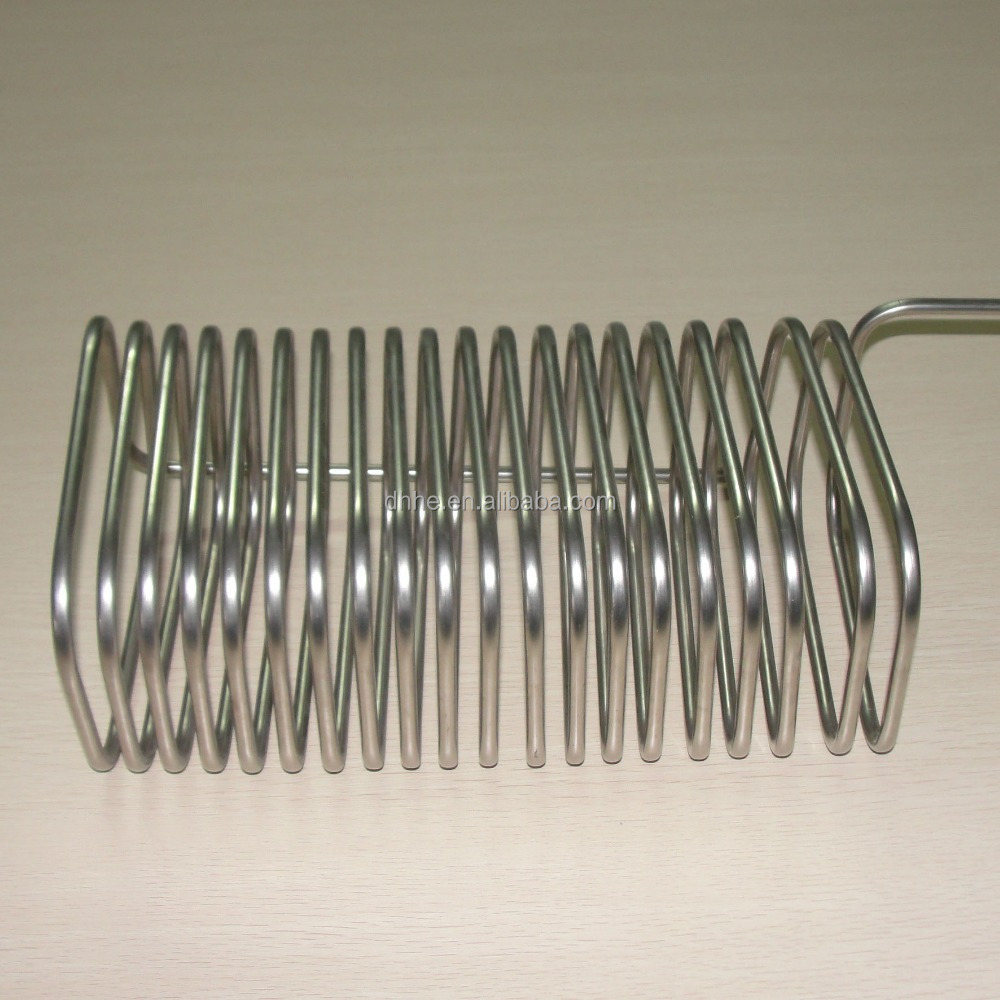

beverage cooling,bear cooling,wort chiller, beer cooling,wort chiller,beverage cooling

-

Outer Diameter:

-

8mm

-

Certification:

-

RoHS

-

Material:

-

AISI304,304L,316,316L

-

Surface:

-

polishing

-

Package:

-

capped the end and packed with cartons

-

End forming:

-

threaded,beads,expension,flaring,swage or welded with fittings

Quick Details

-

Type:

-

Welded

-

Steel Grade:

-

304

-

Tolerance:

-

±5%

-

Grade:

-

300 Series

-

Surface Finish:

-

2B

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

RATO

-

Model Number:

-

AISI 304

-

Application:

-

beverage cooling,bear cooling,wort chiller, beer cooling,wort chiller,beverage cooling

-

Outer Diameter:

-

8mm

-

Certification:

-

RoHS

-

Material:

-

AISI304,304L,316,316L

-

Surface:

-

polishing

-

Package:

-

capped the end and packed with cartons

-

End forming:

-

threaded,beads,expension,flaring,swage or welded with fittings

The tube bending parts are widely used for heat exchangers,cooler,heating in food processing industry, solar energy system and different type of heat recovery application. The tube bending coolers are made according to the customer's design.We can bring stable high precision to the bending dimensions and you can be reassured about the quality and assembly issue after bringing back the parts to use.

OUTSTANDING FEATURES AND ADVANTAGE:

1. We execute ISO9001 fully in the company. Besides the Quality System, we use advance quality controlling tools for our quality management and development, like APQP and SPC. You can be reassured that all of our output is meeting the standard and stable in the quality.

All items are performed testing before delivery. The deliveries to you will go with a quality report for the dimensions & material and leakage testing

2. Basing on our bending technic the bending diameter lose is small, with the least tube ovality the tube coils provide the minimum pressure drop to the flow inside the heat exchanger. You can save material cost by reducing the tube size for the same flowing area in another word.

3. Both the coils' diameters and the pitches can be fixed or variable. This allows you to optimized the heat transferring area to your system and increase the heat transferring efficience.

4.There are different types of tube end forming available, like beads, expansion, flaring, reduction/swage and thread cutting directly to the inlet/outlet of the tube bending coils.

5. We have different type of tube bending machines and production lines to meet your fast delivery request and cost saving strategy. We have CNC bending machines and a number of semi-automatic bending machines which can produce over 10,0000pcs per month. With our tooling ability and technology we can customized the special lines for your high volume orders for the tube bending parts.

QUALITY CONTROLLING:

OUR FACILITIES:

PACKAGING AND STORAGE OF OUR PARTS:

GLOBAL MARKETING: