- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depends

-

Weight:

-

Depends

-

Certification:

-

ISO

-

Color:

-

Blue White,Customized

-

Usage:

-

Screening,washing,dewatering,recycling

-

superiority:

-

Manufacturer guards you the good quality and low price

-

Spare parts supply:

-

Life long provide

-

New tech:

-

Combine

Quick Details

-

Capacity(t/h):

-

Depends

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LDHB

-

Dimension(L*W*H):

-

Depends

-

Weight:

-

Depends

-

Certification:

-

ISO

-

Color:

-

Blue White,Customized

-

Usage:

-

Screening,washing,dewatering,recycling

-

superiority:

-

Manufacturer guards you the good quality and low price

-

Spare parts supply:

-

Life long provide

-

New tech:

-

Combine

Product Description

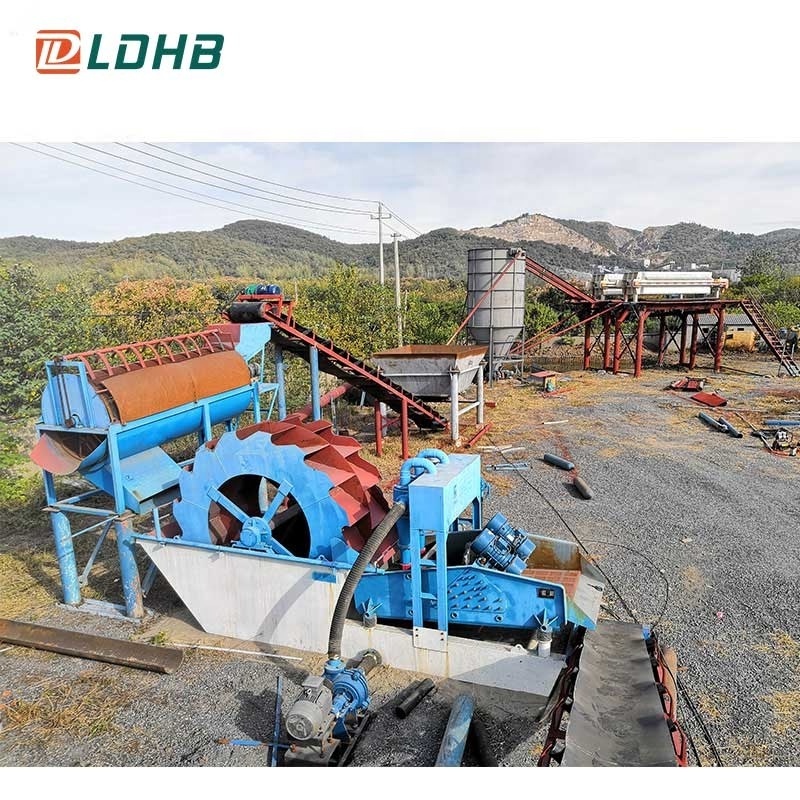

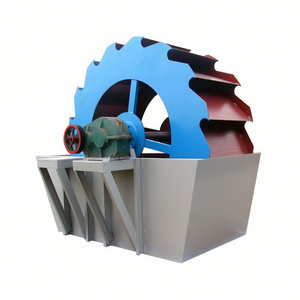

SX series sieve washing and washing machine combines drum sieve, bucket sand washing machine, separator, dewatering screen and other equipment in one, so that the equipment has the functions of screening, washing, dewatering and recycling.

Working Princple

*Screening: The Trommel Screen is also called rotary screen or drum screen, which screening the material into different size.

*Washing: The bucket is driven by the motor through the reducer and rotates in circle. There are many sand storage web grooves and bucket screen for sand storage and primary dewatering. When the bucket moves, sand can be put out by sand storage web groove after being cleaned in the cleaning tank and primary dewatered on the bucket screen. *Recycling: Flowing slurry water is extracted by slurry pump, fine sand is collected by the centrifugal force of the cyclone, then fed to the polyurathane screen from the apex spray. The 0.16-3mm fine sand and water are efficiently separated through the vibration screen.

*Dewatering: coarse sand (3-10mm) and fine sand (0.16-3mm) are fed onto polyurathane vibrating screen for dewatering.

-

Features

1.Flexibility, high production rates, serviceability and low maintenance.

2.Compact structure, saving land area.

3.High efficiency and cost saving.

Size Information

|

Model |

Impeller diameter

(mm) |

Trommel

size (mm) |

Sieve plate size

(mm) |

Productivity (m³)

|

Power

(kw) |

Weight

(kg) |

Overall Dimension

(L*W*H) (mm) |

|

SX10-26-55-1224

|

2600

|

1000*3000

|

1200*3400

|

20-140

|

35.9

|

7700

|

7345*4980*2980

|

|

SX12-30-65-1530

|

3000

|

1200*3000

|

1500*3000

|

40-80

|

525

|

10900

|

7705*5560*3070

|

|

SX15-36-75-1842D

|

3600

|

1500*3000

|

1800*4200

|

80-150

|

68.5

|

18500

|

5800*5560*3662

|

|

SX15-36-75-2442J

|

3600

|

1500*3000

|

2400*4200

|

150-180

|

72.5

|

20000

|

6500*6450*3662

|

Packing & Delivery

|

Packaging

|

|

|

|

Model

|

SX15-36-75-1842D

|

|

|

Size

|

5800(L) * 5560 (W) * 3662 (H)

|

|

|

Weight

|

18500KG

|

|

|

Packaging details |

The normal package is plastic cloth for main machine and wooden for parts.The wooden box will be fumigated, can also pack it according to customers special request. |

|

|

Packaging

|

|

|

|

Model

|

SX15-36-75-2442J

|

|

|

Size

|

6500 (L) * 6450 (W) * 3662 (H)

|

|

|

Weight

|

20000KG

|

|

|

Packaging details |

The normal package is plastic cloth for main machine and wooden for parts.The wooden box will be fumigated, can also pack it according to customers special request. |

|

After Sales Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Servic

e

* Training how to instal the machine, training how to use the machine.

* 24hours for technical Operation Guide and 4hours offer technical proposal for problem shooting.

Company Introduction

Related Products

Hot Searches