- Product Details

- {{item.text}}

Quick Details

-

Center Height (mm):

-

1000 mm

-

Max.Transformer Capacity(kVA):

-

1600 kVA

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DESG

-

Motor Power (kw):

-

4

-

Weight (KG):

-

800

-

Dimension(L*W*H):

-

2800x800x1300

-

Wire Diameter Range (mm):

-

0.3 - 10 mm

-

Product name:

-

Horizontal Winding Machine

-

Used for:

-

High Frequency Transformer

-

Function:

-

Coil Winding Tool

-

Power supply:

-

Three-phase Four Wire 380v/customized

-

Keyword:

-

Automatic Motor Wire Winding Machine

-

Tailstock adjustment range:

-

1000-1400mm

-

Disc diameter:

-

220mm

-

Speed range:

-

0~200r/min

-

Packaging:

-

Wooden Box

-

Certification:

-

CE ISO

Quick Details

-

Max. Load (KG):

-

1000 KG

-

Coil Type:

-

High and low voltage transformers

-

Length of Axis (mm):

-

1100 mm

-

Center Height (mm):

-

1000 mm

-

Max.Transformer Capacity(kVA):

-

1600 kVA

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DESG

-

Motor Power (kw):

-

4

-

Weight (KG):

-

800

-

Dimension(L*W*H):

-

2800x800x1300

-

Wire Diameter Range (mm):

-

0.3 - 10 mm

-

Product name:

-

Horizontal Winding Machine

-

Used for:

-

High Frequency Transformer

-

Function:

-

Coil Winding Tool

-

Power supply:

-

Three-phase Four Wire 380v/customized

-

Keyword:

-

Automatic Motor Wire Winding Machine

-

Tailstock adjustment range:

-

1000-1400mm

-

Disc diameter:

-

220mm

-

Speed range:

-

0~200r/min

-

Packaging:

-

Wooden Box

-

Certification:

-

CE ISO

Product Description

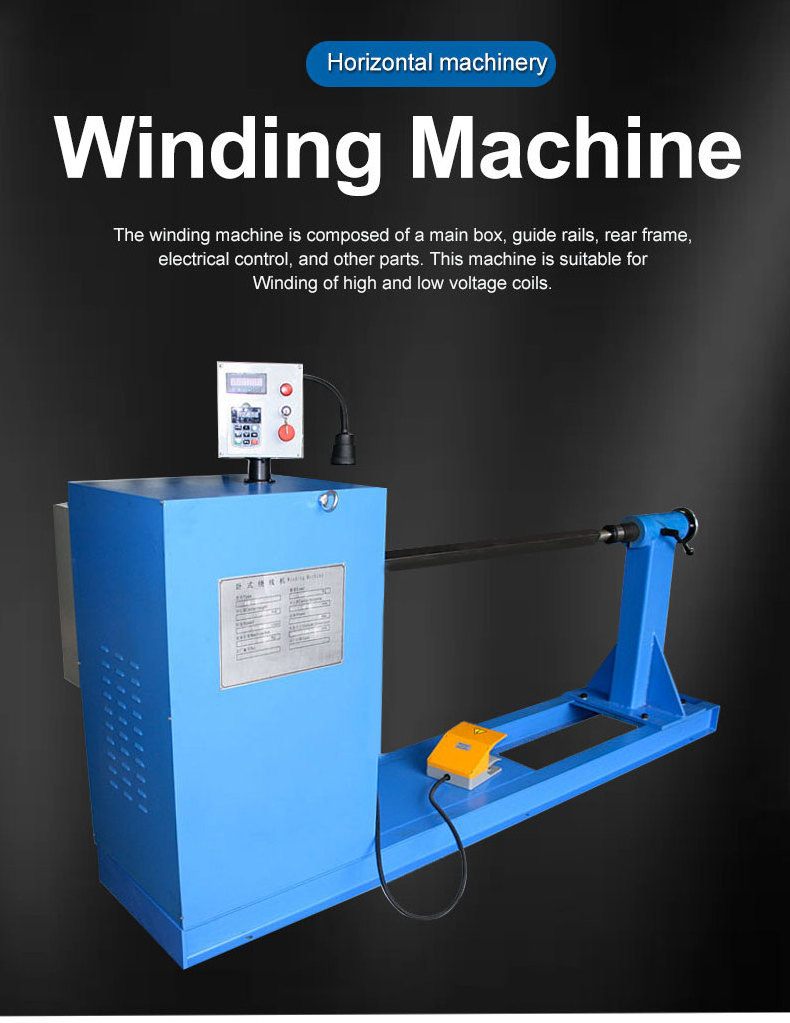

New Technology Toroidal Copper Coil Winding Machine Horizontal Style Transformer Winding Machine

Product composition:

The equipment consists of a main box, guide rails, rear tailstock, and electrical control components.

The equipment consists of a main box, guide rails, rear tailstock, and electrical control components.

Structural characteristics

(1)

The mechanical transmission part of the winding machine is located in the headbox, and the transmission part is installed on the operating side of the headbox. Realize high and low spindle speed changes through the variable speed handle.

(2)

The winding machine adopts a frequency converter to achieve stepless speed regulation, with smooth starting and constant torque. There are three positions for adjusting the gear lever: low speed position, neutral position, and high speed position; Set the number of laps and automatically stop.

(3)

The machine is equipped with an automatic brake system to prevent reverse when the winding stops.

(4)

The machine can preset the number of coil turns and control forward and reverse rotation; The electronic reversible meter has a forward and reverse counting accuracy of 1/10 turn and has a power-off memory function.

(5)

The button station is centrally controlled, and the start and stop of the spindle flower tray are controlled by foot switches or buttons.

Technical Parameters

|

Model

|

DSJYJ-1000

|

|

Center height (mm)

|

1000mm

|

|

Disc diameter (mm)

|

Φ220mm

|

|

Main wheelbase ground high

(mm)

|

1100mm

|

|

Tailstock adjustment range

|

1000-1400mm

|

|

Maximum spindle torque

|

1500N.M

|

|

Motor rating

|

4kw

|

|

Overall dimension

|

2800X600X1200

|

|

Speed range

|

0-200r/min

|

|

Maximum bearing capacity

|

1000kg

|

Technical Description

1. Main box

Composed of a casing, transmission system, variable speed handle, motor, etc. The secondary mechanical variable speed of the spindle box and the stepless speed regulation of the variable frequency motor form the joint speed regulation system of the main engine, ensuring a smooth starting process and accurate and reliable braking of the entire equipment. The motor torque is amplified by the main axle box deceleration, providing winding torque. Mechanical variable speed has two gears, high and low, with variable frequency and stepless speed regulation for each gear.

2. Guide rail and tailstock section

The tailstock is integrated with the main engine box, mainly composed of a tailstock, guide rails, etc. The tailstock can be manually moved axially on the guide rails of the base to meet the needs of different length line molds. By rotating the handwheel, the rear top can be extended or retracted, making it convenient to move the mold up and down and improving strength. The locking handle can lock the roller, tighten the coil, and support its weight.

3. Electronic control system

The electronic control system consists of an electrical control cabinet, frequency converter, electronic counter, foot switch, and other electrical appliances. The speed of the spindle is controlled by a frequency converter, and the spindle speed, number of turns, and can all be displayed. The counter can count both forward and backward, and has the function of power-off memory and automatic parking after setting the number of turns. The electronic counter can operate the entire winding process with a foot switch, with a value range of 0-9999 turns.

Product Details

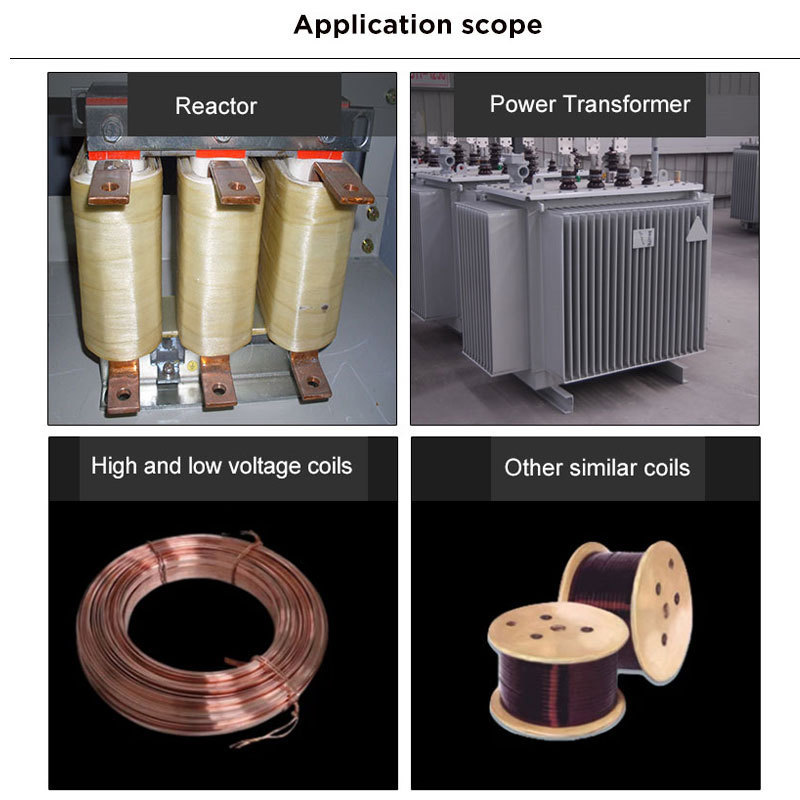

Product applicability

Transformer winding machine is suitable for winding high and lowvoltage coils of reactors , power transformers , and other similar coils.

Packed in standard import and export wooden boxes, free from fumigation and treated with rust prevention.

Hot Searches