- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

4.5kw

-

Dimension(L*W*H):

-

About 1800*1450*2250mm

-

Weight:

-

4500 Aboutkg

-

Capacity:

-

1500 pieces/hour

-

Drying:

-

electric heating

-

Color:

-

Gray-white

-

Forming machine:

-

Reciprocating type

-

Finished products:

-

pulp tableware

-

Mold material:

-

aluminum

-

Forming machine frame and cover:

-

stainless steel

-

Raw material:

-

pure wood pulp

-

Moulds quantity:

-

2 pieces aluminum moulds

-

Tableware mould type:

-

customized as buyer needs

Quick Details

-

Production Capacity:

-

42 pcs/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PFK

-

Voltage:

-

380V 50HZ

-

Power:

-

4.5kw

-

Dimension(L*W*H):

-

About 1800*1450*2250mm

-

Weight:

-

4500 Aboutkg

-

Capacity:

-

1500 pieces/hour

-

Drying:

-

electric heating

-

Color:

-

Gray-white

-

Forming machine:

-

Reciprocating type

-

Finished products:

-

pulp tableware

-

Mold material:

-

aluminum

-

Forming machine frame and cover:

-

stainless steel

-

Raw material:

-

pure wood pulp

-

Moulds quantity:

-

2 pieces aluminum moulds

-

Tableware mould type:

-

customized as buyer needs

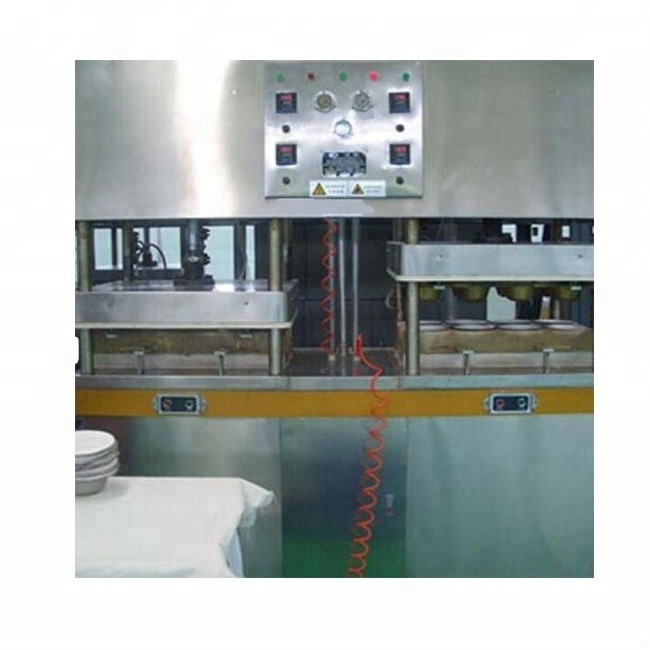

Biodegradable disposable paper pulp tableware molding making machine

Fully automatic production, tableware forming, drying and shaping processes are automatically completed in one machine with high degree of automation.

The application of internationally renowned brand control accessories, the machine performance is stable and reliable, and the failure rate is low.

Wide range of applications, the replacement of molds can produce a variety of pulp plates of different sizes and thicknesses

Production capacity: 1500 pieces/hour

Drying: electric

Required workshop sizes: 200 square meter

Big capacity disposable pulp tableware moulding making machine

Production capacity: 15000 pieces per hour

Raw material: pure wood pulp

Finished products: disposable tableware plate

Drying: electric heating by reforming machine

Vacuum forming machine material: stainless steel

Tableware plate moulds: can be designed as buyer requirement

Paper pulp egg tray vacuum moulding machine

Waste paper recycling egg holder tray vacuum moulding machine used to produce paper egg tray, mainly consist of waste paper recycling pulping system, 8 faces rotary paper pulp moulding machine, egg tray forming moulds, vacuum pumps etc, and the production capacity is 3000-3500 pieces/hour ( other shape paper packaging trays capacity are different); You can chose to match single layer or multi-layer metal drying oven as your workshop sizes.

Whole plant of the biodegradable egg tray production line

2500 pieces/hour disposable egg tray vacuum moulding machine

Related single or multi-layer metal drying oven, waste paper feeding conveyor, hydrapulpers and vaccum pumps are also available from us. And you can also produce egg box tray, paper apple tray, paper shoe tree, paper vegetable trays, cup holder trays etc by changing molds on our egg tray producing machine.

We produce all kinds of paper pulp tray moulding machine ( also known as egg tray machine, or paper tray forming machine ) , turning templates mini egg tray making machine,traditional reciprocating small egg tray forming machine , automatic rotary drum egg tray making machine, etc; For our rotary egg tray making machine, it is developed as Germany technology, and we improved the motors, driving system to get higher production capacity but more energy saving; Depending on the heat drying system can be divided into : diesel oil drying , natural gas drying , electric stove heating and wood or coal drying( brick drying oven) , which can meet the needs of different investors.

(Paper pulp apple tray moulding machine)

Packging of our egg tray vacuum moulding machine

Plastic film wrap the paper egg tray moulding making machine, then load into container directly.

Shipment for our egg tray vacuum moulding machine

Delivery from Tianjin or Qingdao seaport

Shipment of the paper pulp tray molding making machine

| Item | Paper pulp molding tableware making machine without dryer | Paper pulp molding tableware making machine with metal dryer |

| Loading containers | 1*40”HQ | 4*40"HQ |

Pre-sales service for our disposable paper pulp tableware making machine

* any questions about our egg tray forming machines by email/phone will be replied within 24 hours

* according to the customers’ requirements and circumstance to recommend the best egg tray production lines

* cost/benefit analysis according to your budget plan

* to support factory layout design and construction

* design the egg tray/fruit tray mould for you according to your needs ( you need to pay for the new mould develop cost)

In the sale of services for ordered biodegradable pulp tableware making machine

* we are in charge of installing,debugging and training

* technical guidance of frequently asked questions

After-sales service for the installed biodegradable disposable pulp tableware making machine

* one year guarantee for whole machine except of quick-wear part

* 24 hours technical support online

www.pefct.com

Skype: vastsea-777

What's app: 008618561832088

* quick wear parts supply and maintainence instruction.

What you might want to know about our paper pulp tray making machine, disposable fiber pulp tableware plate making machine

* What is the egg tray making machine’s frequency, can it apply 60Hz?

Yes, our machine can use 50Hz and 60Hz; 220V,440V motors can be customized.

* What is the raw material for paper egg tray making ? and how about the material for disposable tableware plates ?

Generally, waste office paper,newspaper,old magazine, carton board and other kinds of waste paper material. You can also make use of waste pulp from paper machine factory; For the tableware plates production, the raw material ususally use sugarcane fiber pulp, straw fiber pulp, bamboo fiber pulp.

* Which kind of fuel can be used in the drying system? What type drying method for the tableware plates production?

Electricity, 0# diesel oil, heavy oil, natural gas, LPG, coal and rice husk for the dried hot press paper pulp trays production. For disposable tableware plates production, the drying is achieved by the wet hot press molds, after molding production, the tableware plates will be dried on the wet hot press machine by the hot press molds.

* What is the main parts of the fiber pulp tableware plates production line ?

Main two parts are pulping system and Tableware forming hot press machine; We design one pulping system to support the require production capacity that you needed per hour, then match the required quantity tableware molding machines; One production line includes more than 2 sets fiber molding machines usually.

* Is there any requirements for the production area of the egg tray's production ?

Different production capacity egg paper tray making machine require different factory layout sizes; For automatic egg tray production line with metal dryer, min required workshop is 45*10*5.0 meter.

* What kinds of other paper tray can be produced by our egg tray production line?

The machine can produce egg tray, egg box tray, fruit tray, cup holder tray, shoe tray, and so on by changing different molds. If you want to produce other paper tray packages, we can design and produce the related molds for you.

* Does is necessary to match the press reforming machine for egg paper tray making ?

Do not need to match hot press reforming machine for egg tray production, but if you want to produce shoe tree, egg carton tray, cup holder tray and other similar trays, need to match the reforming machine and reforming molds to cut the sides and edges after drying.

Working flow of the paper egg tray production line

If any more questions about our biodegradable disposable pulp tableware plates making machine, please contact with us freely !