Brake lining production process:

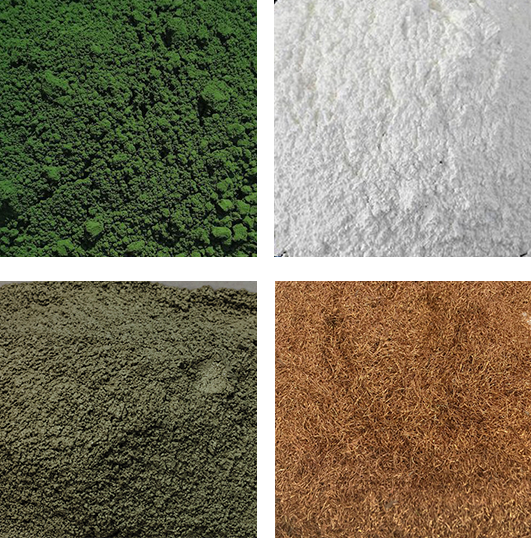

Raw material mixing

Basically the brake skin is composed of steel fiber, mineral wool, foundation, wear-resistant agent, resin and other chemicals, and the friction coefficient wear-resistant index and noise value are adjusted through the proportion distribution of these raw materials.

Hot forming stage

Pour the mixed raw materials into the mold, and pressure molding

Plate treatment

according to different models of iron village after cutting, but also need to pass bead to the surface hardening treatment, in order to glue ready to stick on the brake prototype.

Hot pressing stage

The use of mechanical plate and brake pads high heat pressure, so that the two can be more closely combined, and the manufactured product is called Brake Rough Embryo

Heat treatment stage

In order to make the brake pad village mass energy more stable, heat resistance more painful, so it is necessary to penetrate the heat treatment, the brake rough embryo heating for more than 6 hours, in order to continue processing.

Grinding and Cutting Stage

After heat treatment of the brake pads, the surface still needs to be hairy, so it needs to be polished and cut to be smooth